Pneumatic tire

一种充气轮胎、胎面的技术,应用在特殊轮胎、轮胎零部件、轮胎胎面/胎面花纹等方向,能够解决不能充分满足操控稳定性、乘座舒适性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

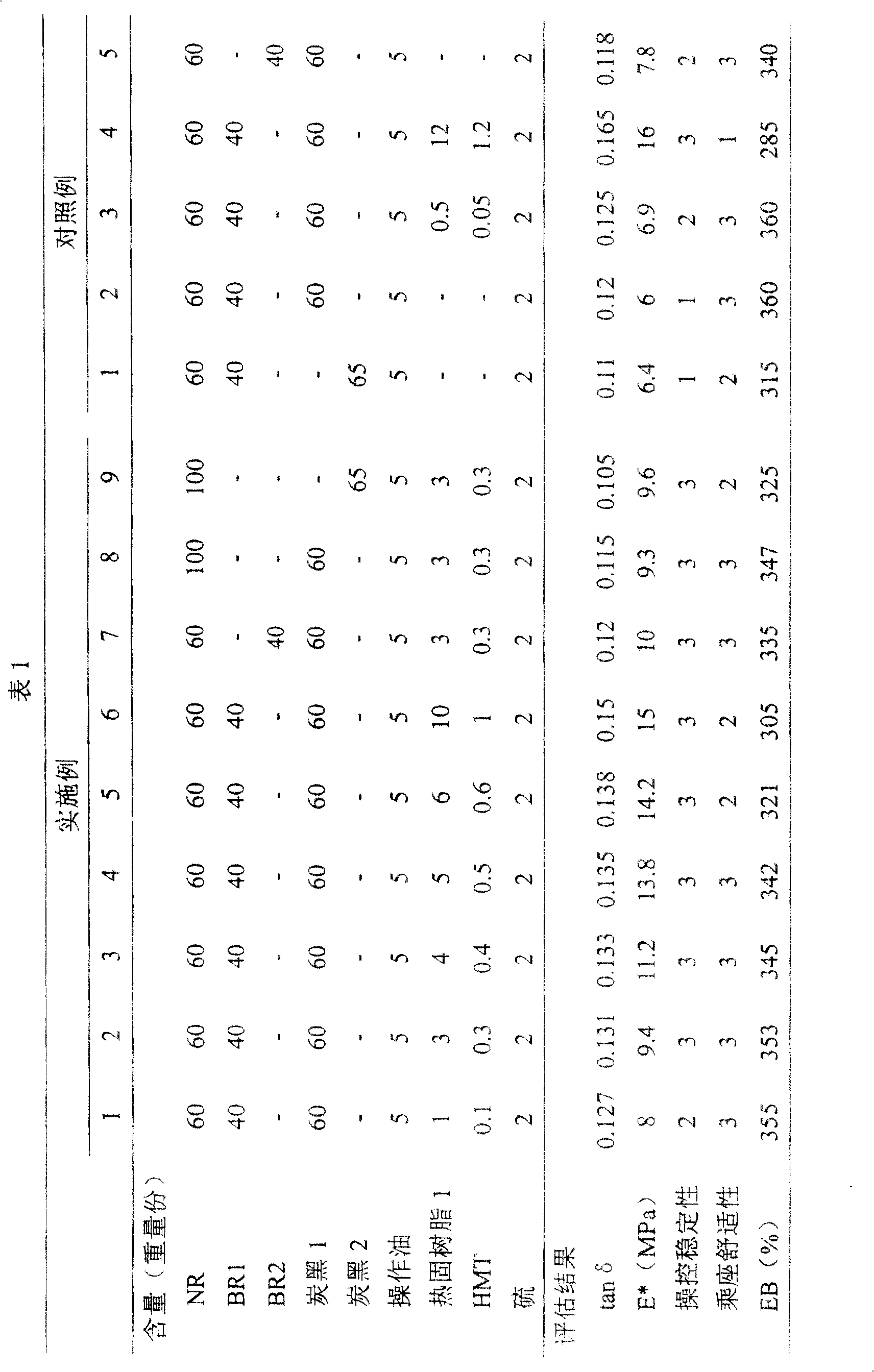

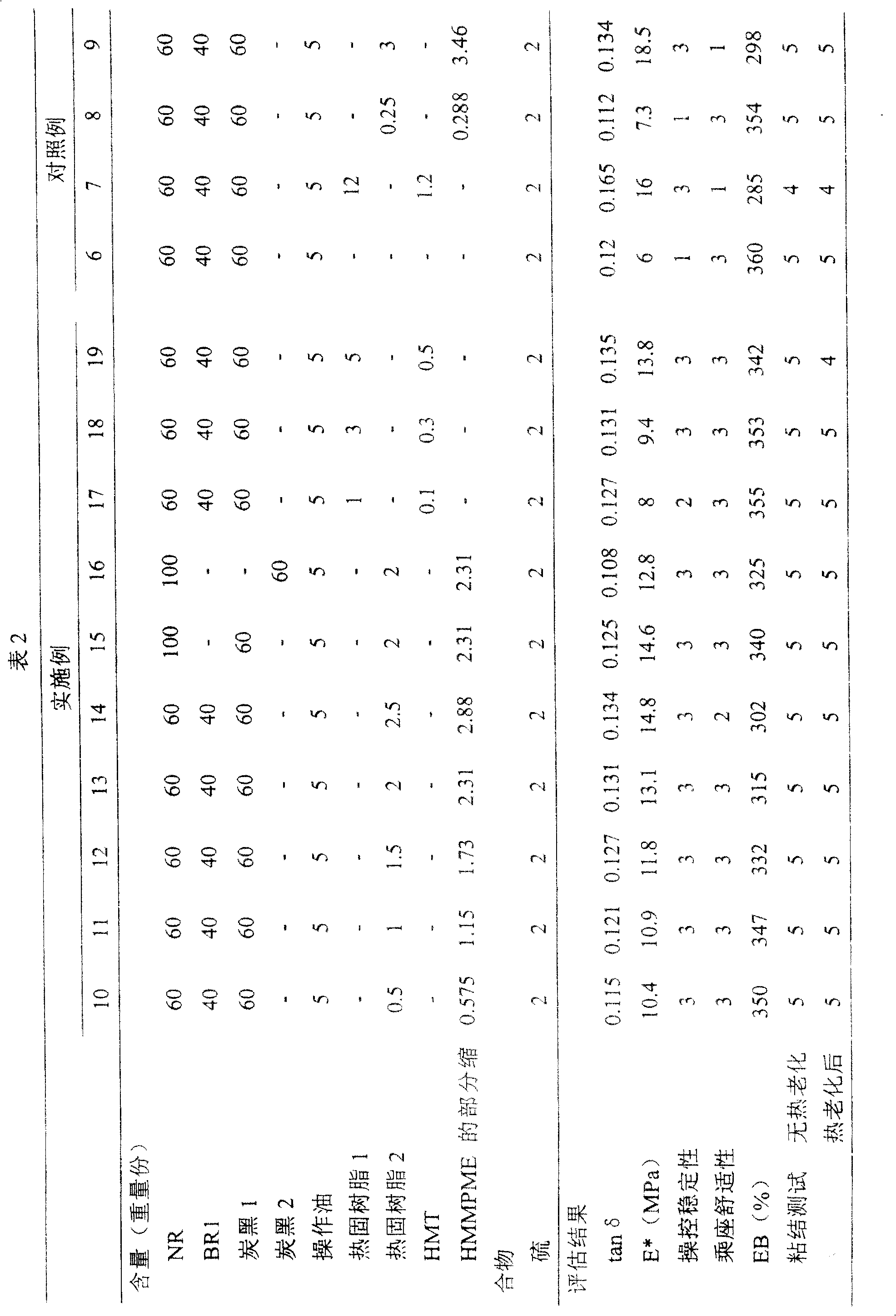

[0036] The present invention will be illustrated by examples, but the invention is not limited thereto.

[0037] Various chemicals used in the examples are described below.

[0038] NR:RSS#3

[0039] BR: BR150B, purchased from Ube Industries Co., Ltd.

[0040] Polybutadiene rubber (VCR) containing syndiotactic-1,2-polybutadiene: VCR412 (syndiotactic-1,2-polybutadiene crystal dispersion), purchased from Ube Industry Co., Ltd.

[0041] Carbon black 1: DIABLACK (N220, N 2 SA: 114m 2 / g), purchased from Mitsubishi Chemical Company

[0042] Carbon black 2: SEAST N (N330, N 2 SA: 74m 2 / g), purchased from Tokai Carbon Co., Ltd.

[0043] Operating oil: DIANAPR CESS AH40, purchased from Idemitsu Kosan Co., Ltd.

[0044] Wax: SUNNOC WAX, available from OUCHI SHINKO Chemical Industry Co., Ltd.

[0045] Antioxidant: OZONONE 6C, purchased from Seiko Chemical Co., Ltd.

[0046] Stearic acid: KIRI, purchased from NOF company

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com