A cabled pipe rack

a cabled pipe and rack technology, applied in the field of cabled pipe racks, can solve the problems of wasting time and arguing, structural engineers are struggling with computer aided load analysis, and delay in project delivery and completion, so as to save time, money, and more benefits for the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

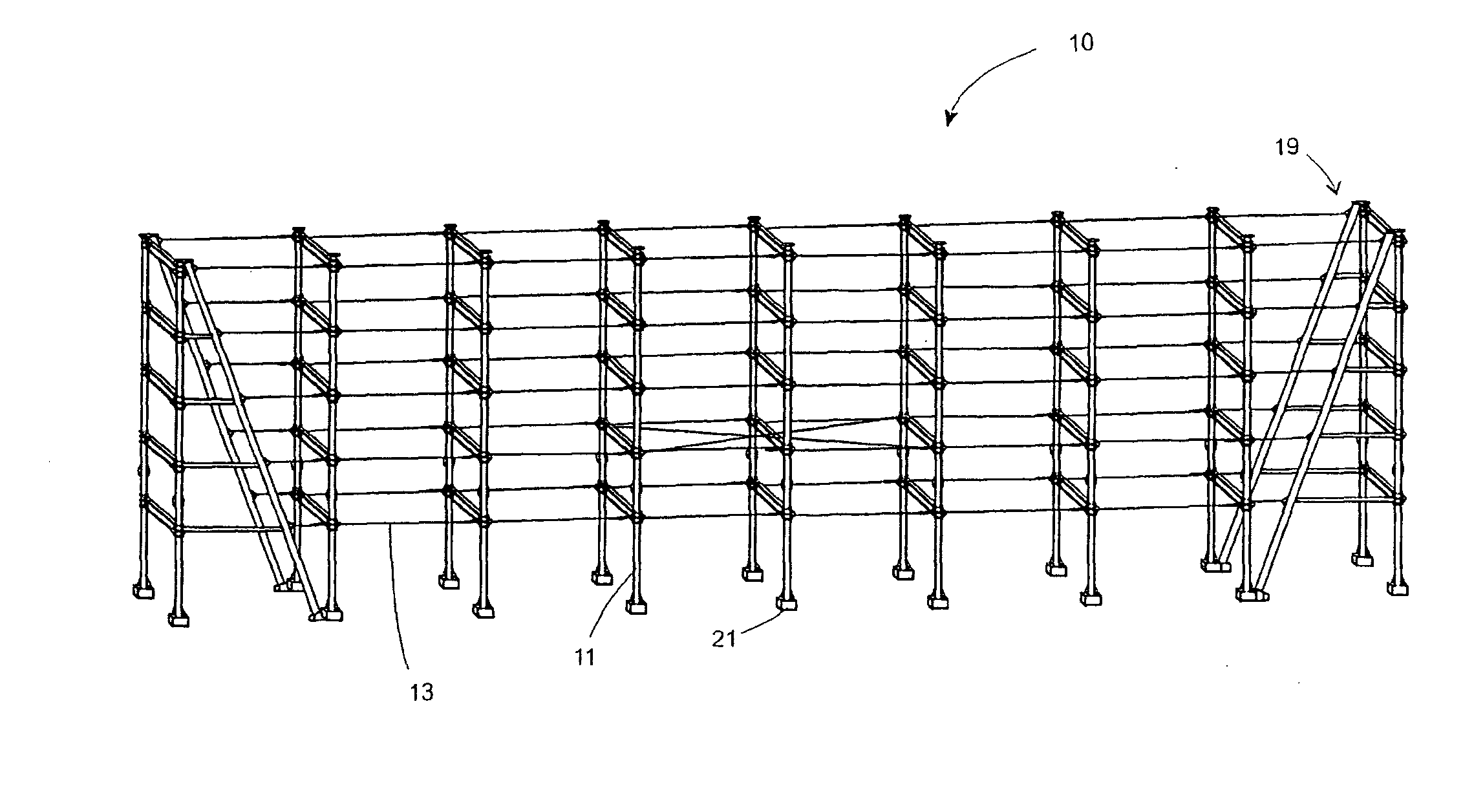

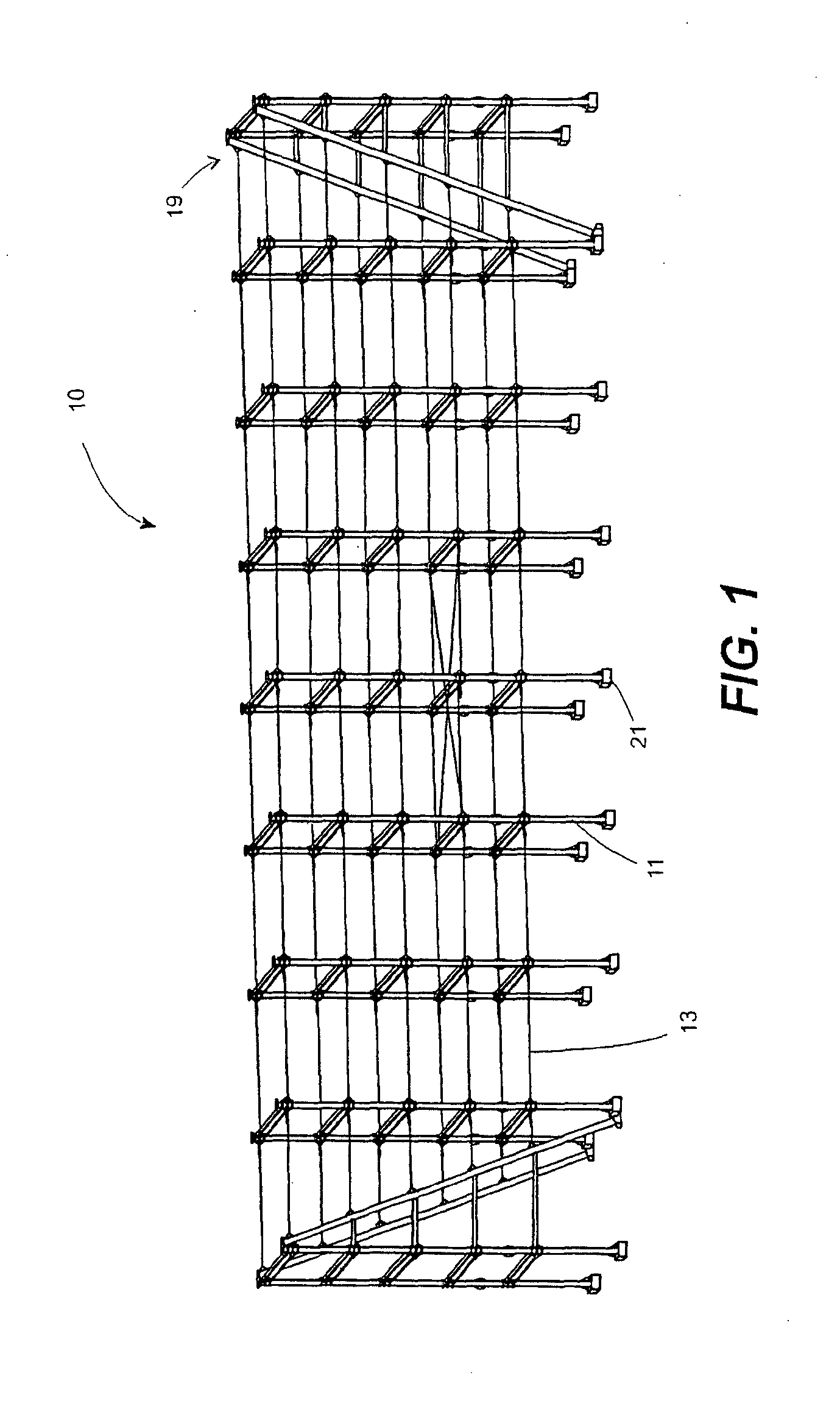

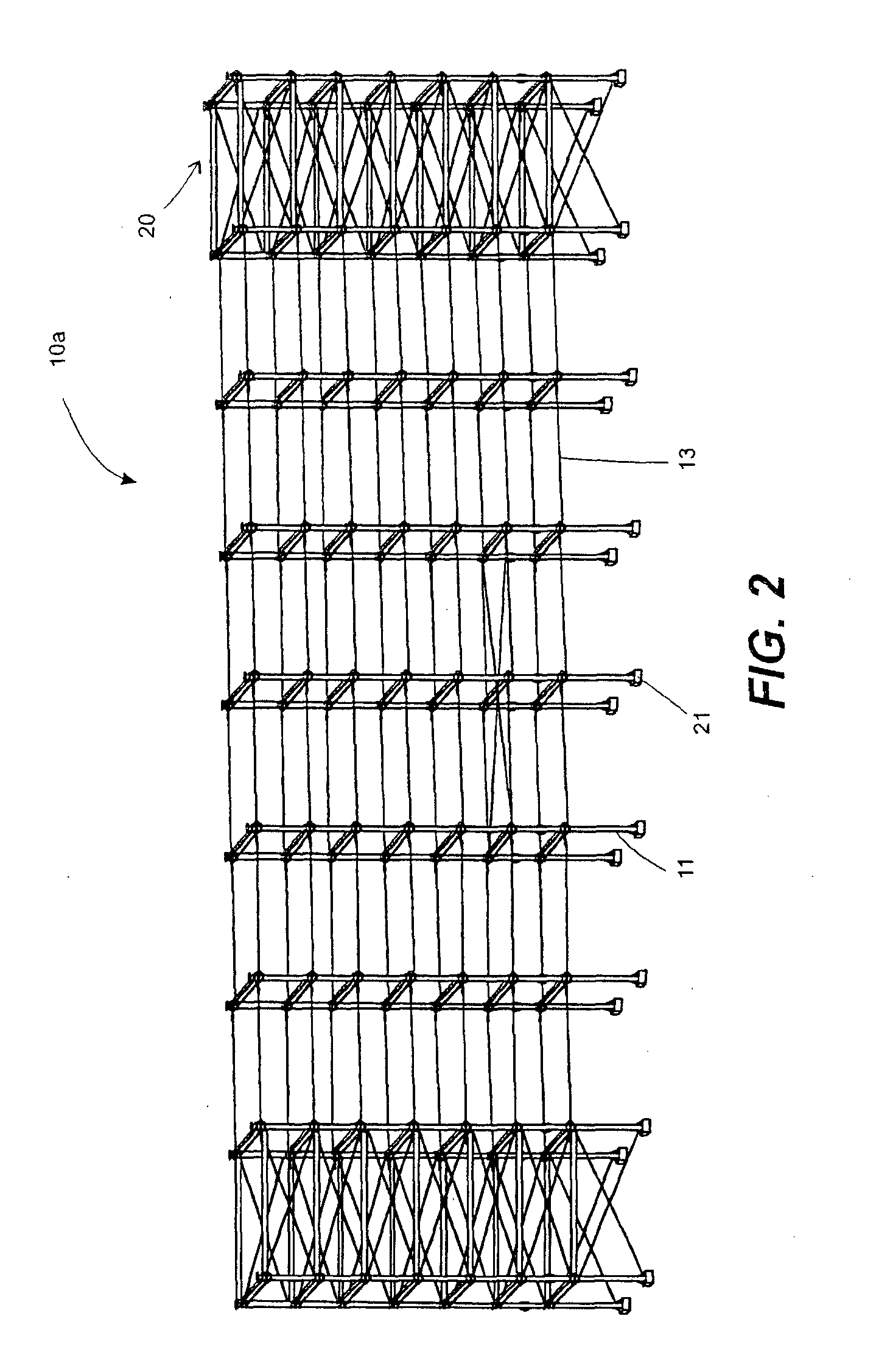

[0039]The invention is directed to rearranging things inside the box. A cabled pipe rack 10 and 10a as shown in FIGS. 1 & 2 will completely function similar to conventional pipe rack but largely of different structural composition, physical appearance and methods of creation.

[0040]The invention is an smart assembly of significant structural elements that have put together to form a robust structural framework simply made up of locally available construction materials, like: tubular hallow steel column 11 (circular, square, and rectangular section), a base plate 12 with a cut-off hole with same size and opening of hallow tubular column, a tension cable rod 13 with shackle 14 at one end and, turn buckle at the other end, an I-beam 15, steel bars 16, and a concrete-mixed material. The above composition of materials, the methods injected and collaborative functions of each element forming the structural system has come up to produce a more robust structural framework of pipe rack struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com