Two-section house refuse incinerator capable of regulating bed of material

A domestic waste incineration, two-stage technology, applied in the field of domestic waste incinerators, can solve the problems of difficulty in actively controlling the thickness of the waste material layer, inability to guarantee the load operation of the incinerator, and high equipment investment costs, achieving simple and reasonable structure and convenient adjustment , The effect of economic renewal and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

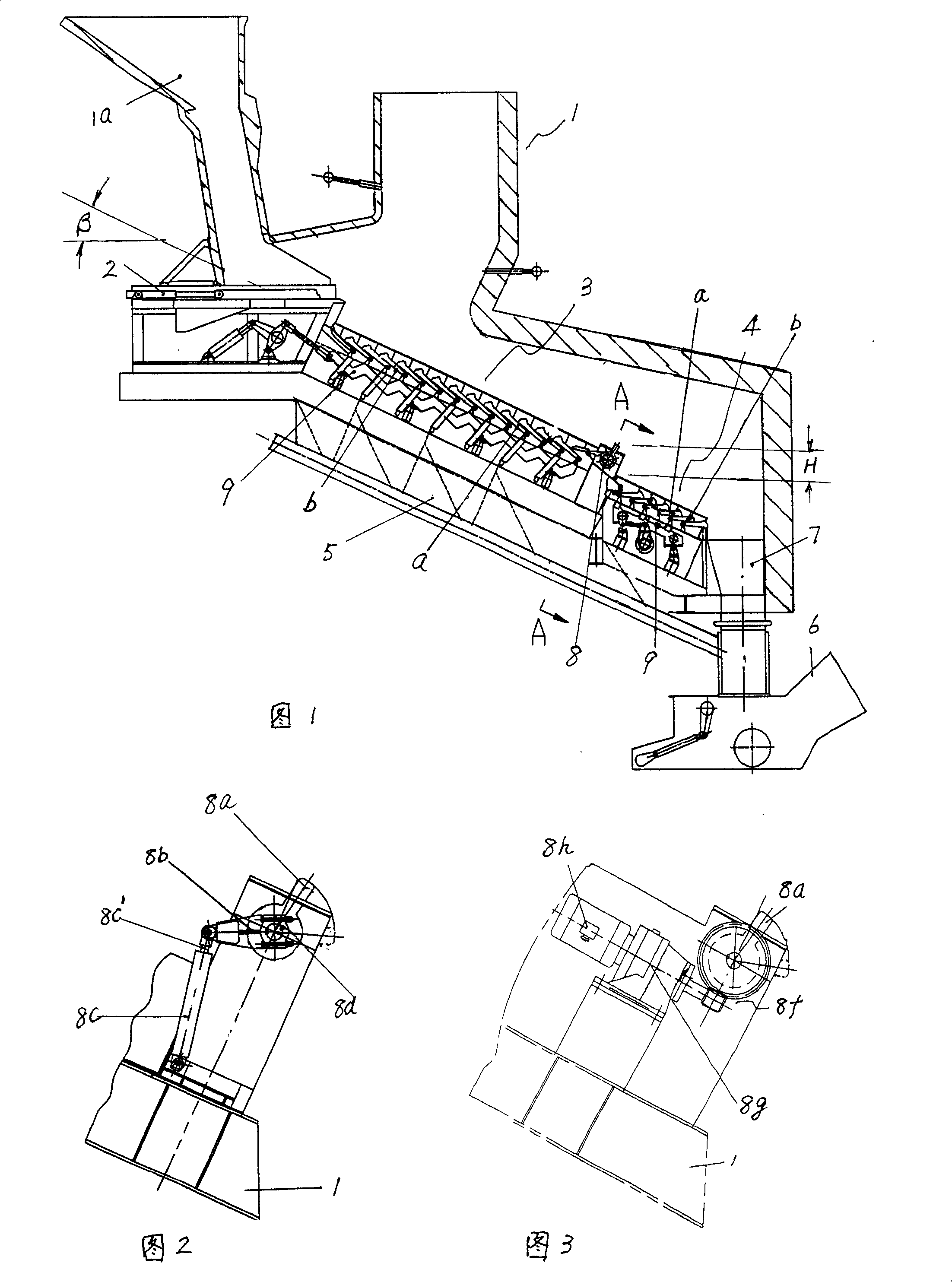

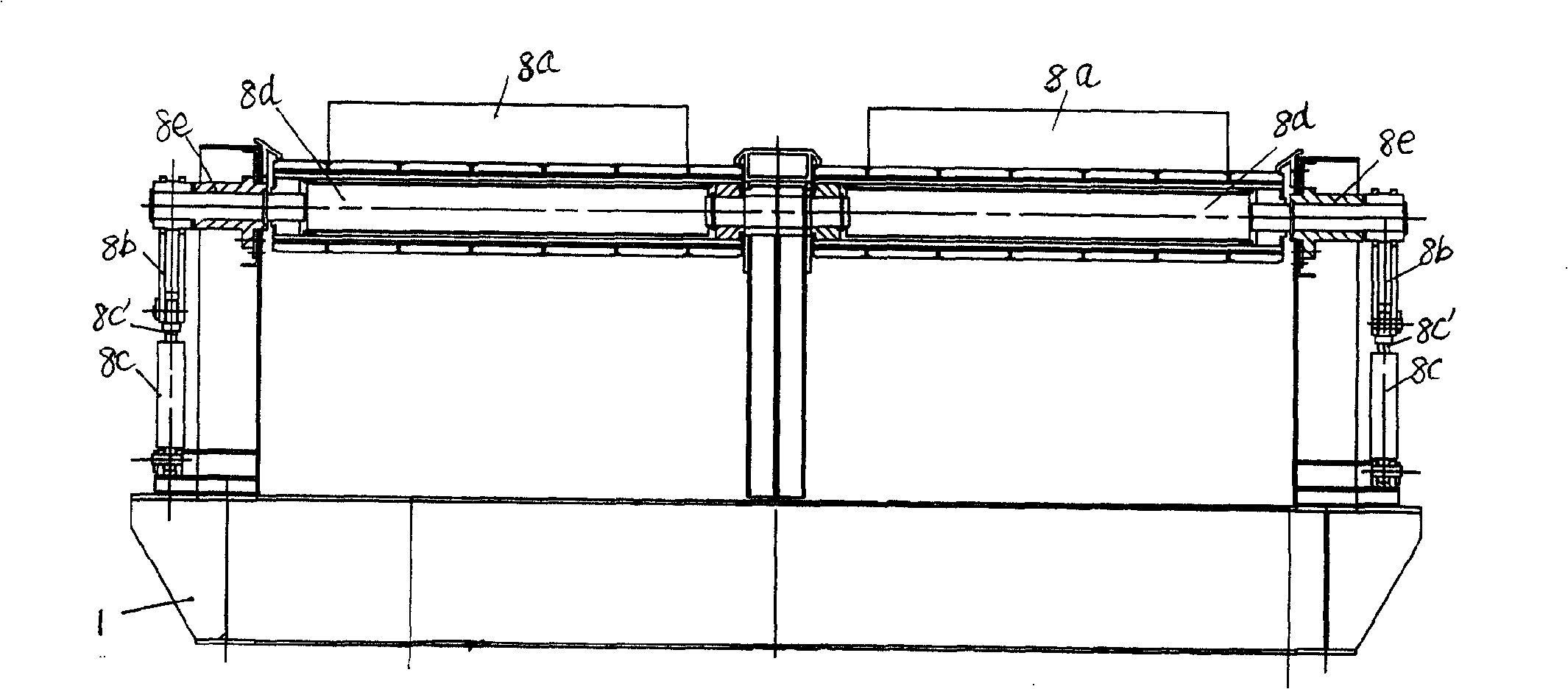

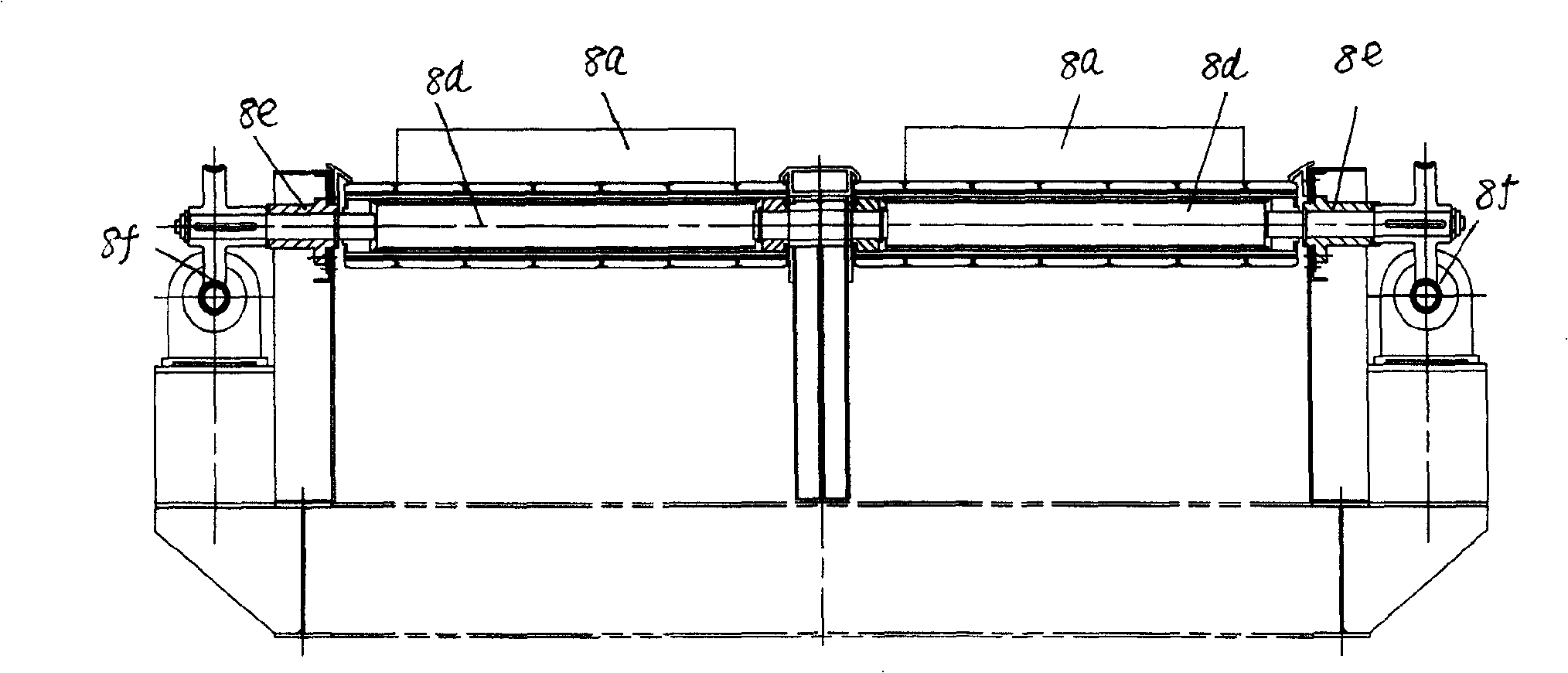

[0014] Embodiment 1, the two-stage domestic waste incinerator with adjustable material layer in this embodiment, its structure can be seen from Figure 1, it contains a furnace body 1 with a blanking groove 1a, a Feeder 2, reverse push type fire grate 3, forward push type fire grate 4, air chamber and ash chamber 5 under the fire grate and slag discharger 6 under the slag discharge channel 7, its fire grate sheet contains solid The fixed piece a bound on the furnace body and the movable piece b arranged between the two adjacent fixed pieces at intervals and connected with the reciprocating rod 9, and the grate is divided into front and rear sections along the running direction of the garbage, close to the falling The front section of the hopper 1 is a downward-sloping reverse-push fire grate 3, and the rear section is a forward-push fire grate 4. A height difference H is provided at the junction of the front and rear two sections of the fire grate; Two rows of two-stage fire gr...

Embodiment 2

[0022] Embodiment 2, the two-stage domestic waste incinerator with adjustable material layer in this embodiment, its structure can be seen from Figure 1, and it differs from Embodiment 1 in that its forward-push fire grate 4 is the best Like the reverse-push grate, it is set to incline to the right and down, and the inclination angle β of the grate to the horizontal direction is 20° to 30°. To ensure that the garbage residue fully incinerated by the reverse-push grate can also stay on the forward-push grate for 10 to 30 minutes, and then leave the grate under the double action of the garbage residue's own gravity and the forward-push grate 4 , into the slag discharge channel 6 and output by the slag discharge machine 7. The slag loss-on-ignition rate of this embodiment is ≤3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com