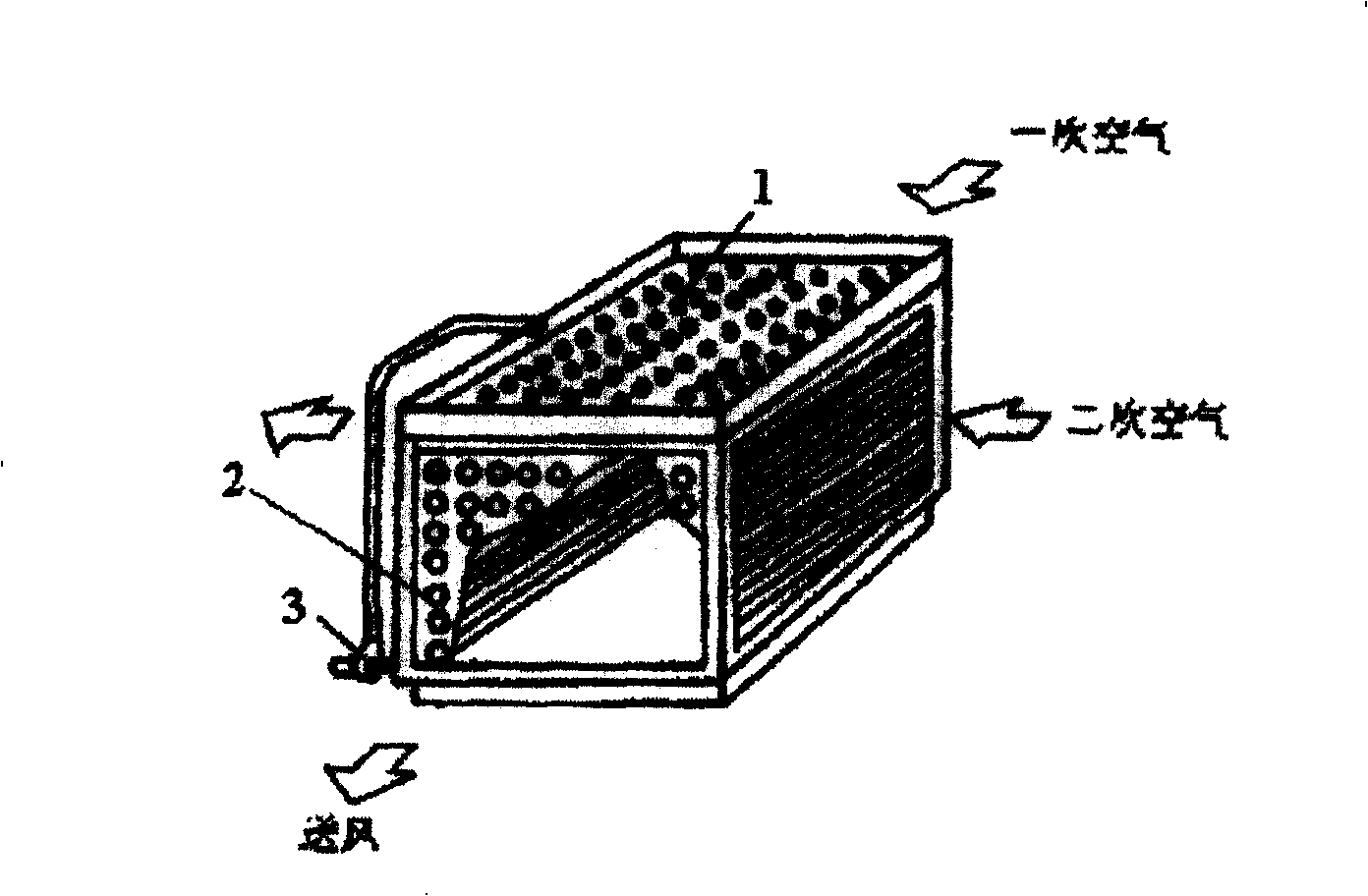

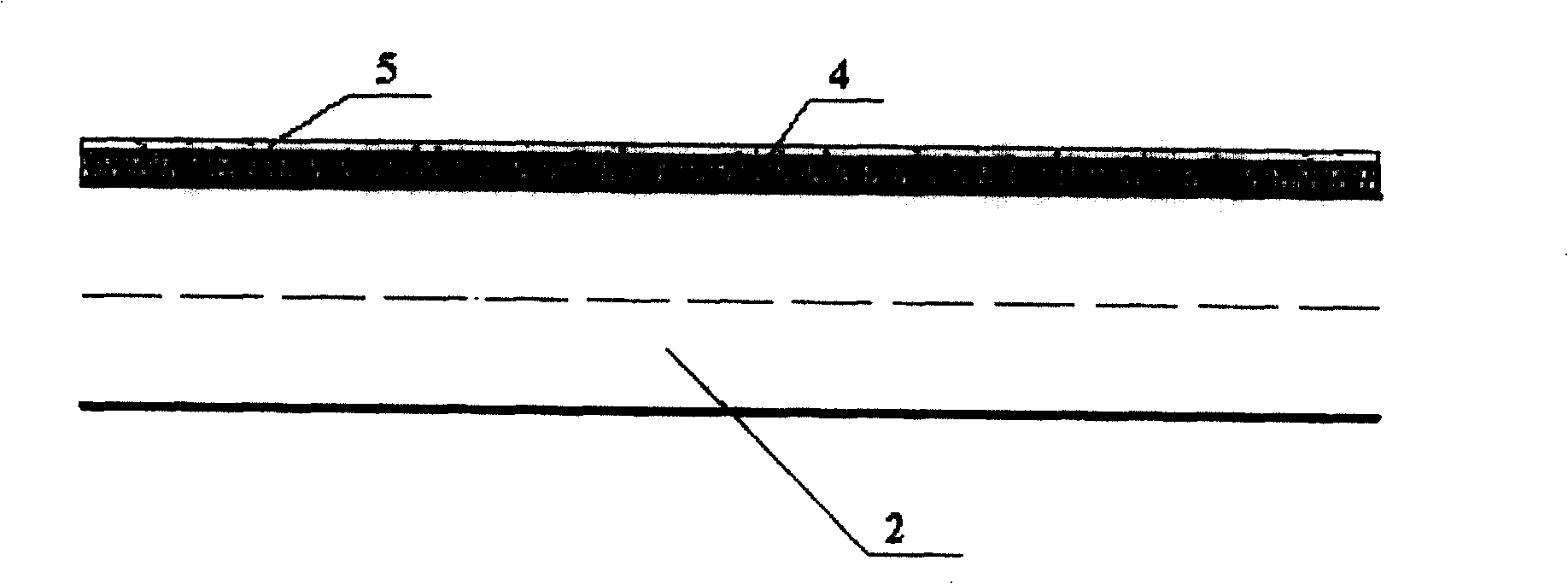

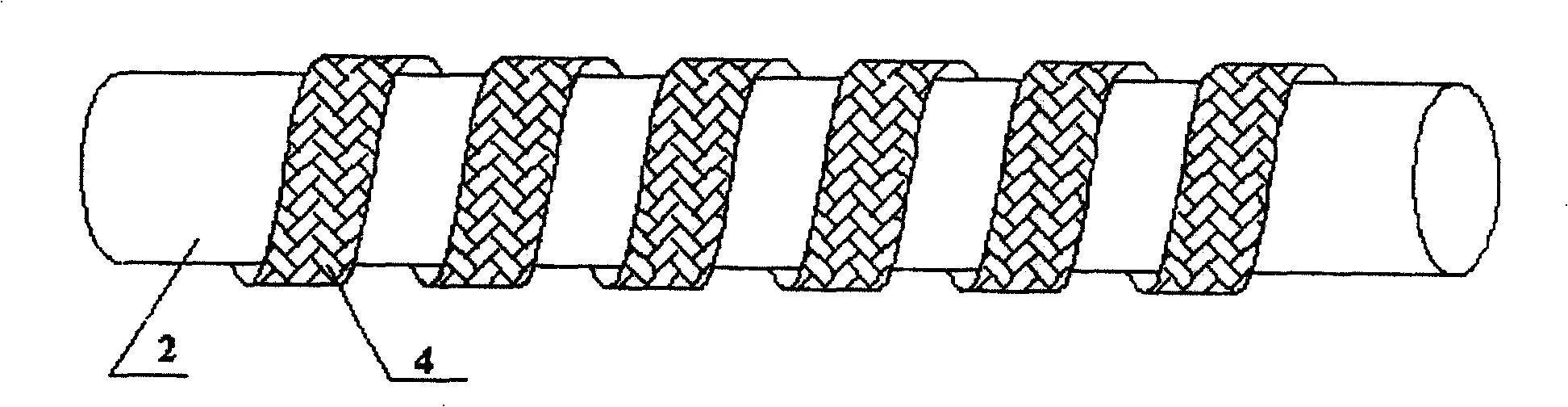

Reinforced tube type indirect evaporation cooler heat exchanging tube outer heat and mass transfer method

An evaporative cooler and heat exchange tube technology, which is applied in heat exchange equipment, lighting and heating equipment, textiles and papermaking, etc., can solve the problems of deformation and decay of fiber sleeves, inconvenient replacement of fiber sleeves, and high requirements for fiber sleeve production processes. To achieve the effect of improving hydrophilicity, increasing the evaporation area outside the tube, and high heat and mass exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Choose rutile titanium dioxide with a particle size of 80-90nm, add it into distilled water to make a suspension with a volume concentration of 10%, add dispersants sodium hexametaphosphate, SiO 2 And cross-linking agent polyethylene glycol diacrylate, the amount of sodium hexametaphosphate added is not more than 1% of the total mass of the dispersion, SiO 2 The amount added is 10% of the total mass of the dispersion liquid, and the amount of polyethylene glycol diacrylate added is no more than 1% of the total mass of the dispersion liquid. Mix and stir, and adjust the pH value of the mixed liquid to 9, and then mix The solution was placed in an ultrasonic cell pulverizer for ultrasonic dispersion for 40 minutes, and the ultrasonic power was controlled at 630W to obtain nano-TiO 2 Hydrophilic dispersion.

[0054] Immerse the Coolplus fiber fabric in the prepared nano-hydrophilic dispersion for 40 minutes, take it out, and then dry it at 50°C to 90°C for 20 minutes.

...

Embodiment 2

[0060] Choose rutile titanium dioxide with a particle size of 80-90nm, add it to distilled water to make a suspension with a volume concentration of 8%, add dispersants sodium silicate, SiO 2 and FH-α cross-linking agent, the amount of sodium silicate added does not exceed 1% of the total mass of the dispersion, SiO 2 The amount added is 40% of the total mass of the dispersion, and the amount of FH-α cross-linking agent added is no more than 1% of the total mass of the dispersion, mixed and stirred, and the pH value of the mixed liquid is adjusted to 10, and then the mixed liquid Put it into an ultrasonic cell pulverizer for ultrasonic dispersion for 20 minutes, and control the ultrasonic power to 450W to obtain nano-TiO 2 Hydrophilic dispersion.

[0061] Immerse 100% stainless steel metal fiber strips in the prepared nano-hydrophilic dispersion liquid for 35 minutes, take it out, and then dry it at 50° C. to 90° C. for 50 minutes.

[0062] Use aluminum foil heat exchange tu...

Embodiment 3

[0067] Choose rutile titanium dioxide with a particle size of 80-90nm, add it to distilled water to make a suspension with a volume concentration of 12%, add dispersants ethylene glycol, SiO 2 and FH-α cross-linking agent, the amount of sodium silicate added does not exceed 1% of the total mass of the dispersion, SiO 2 The amount added is 20% of the total mass of the dispersion, and the amount of FH-α crosslinking agent added is no more than 1% of the total mass of the dispersion, mixed and stirred, and the pH value of the mixed liquid is adjusted to 10, and then the mixed liquid Put it into an ultrasonic cell pulverizer for ultrasonic dispersion for 30 minutes, and control the ultrasonic power to 500W to obtain nano-TiO 2 Hydrophilic dispersion.

[0068] Immerse the metal fiber sintered felt in the prepared nano-hydrophilic dispersion liquid for 35 minutes, take it out, and then dry it at 50° C. to 90° C. for 30 minutes.

[0069] Use aluminum foil heat exchange tubes, wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com