A high-efficiency heat-exchanging, water-saving, demisting wet cooling tower

A wet cooling and cooling tower technology, applied in water shower coolers, heat exchanger types, direct contact heat exchangers, etc. The problem is to reduce the amount of supplementary water, improve the heat and mass exchange efficiency, and enhance the heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

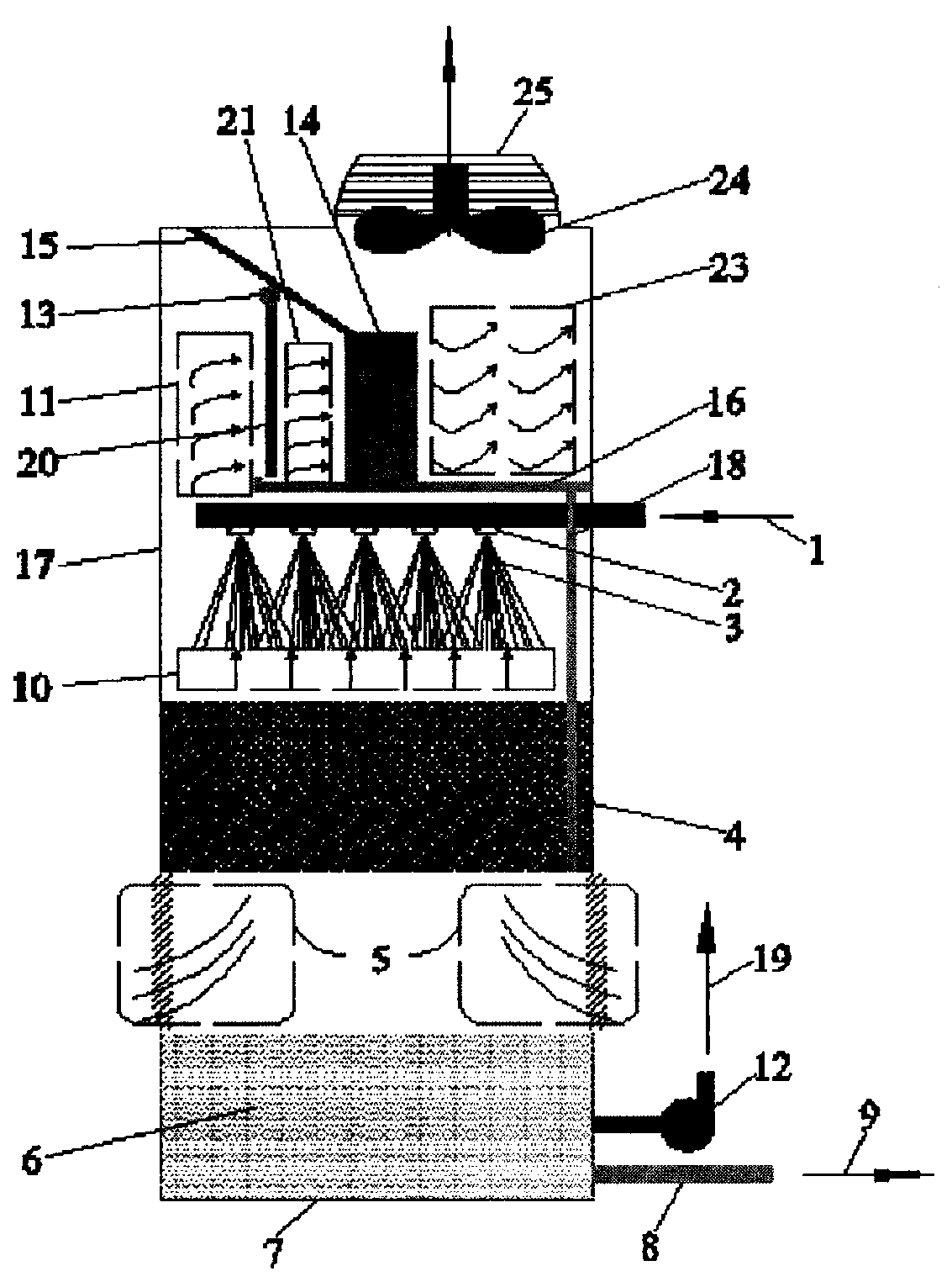

[0049] like figure 1 Shown, a kind of high-efficiency heat-exchanging water-saving water-saving demisting wet cooling tower of the present invention comprises conventional cooling tower structural part, atomizing nozzle (2), waterfall type water collector (13), band baffle plate demister ( 14), sealing wall (15), water collection tank (16), water delivery pipe (18), booster pump (12) and related pipelines;

[0050] The conventional cooling tower structure part mainly consists of tower body (17), packing layer (4), air inlet (5), water storage tank (7), water distribution pipe (1), cooling water outlet (8), fan (24) composition;

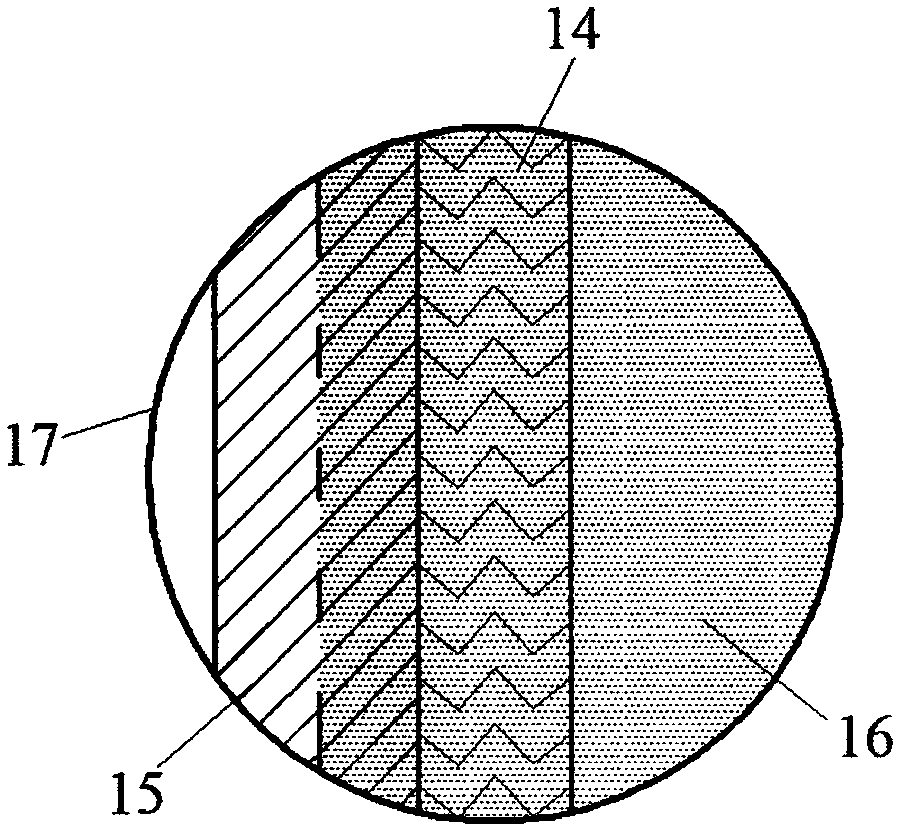

[0051] The tower body (17) is a cylindrical structure, and the tower body (17) is circular in plan view projection;

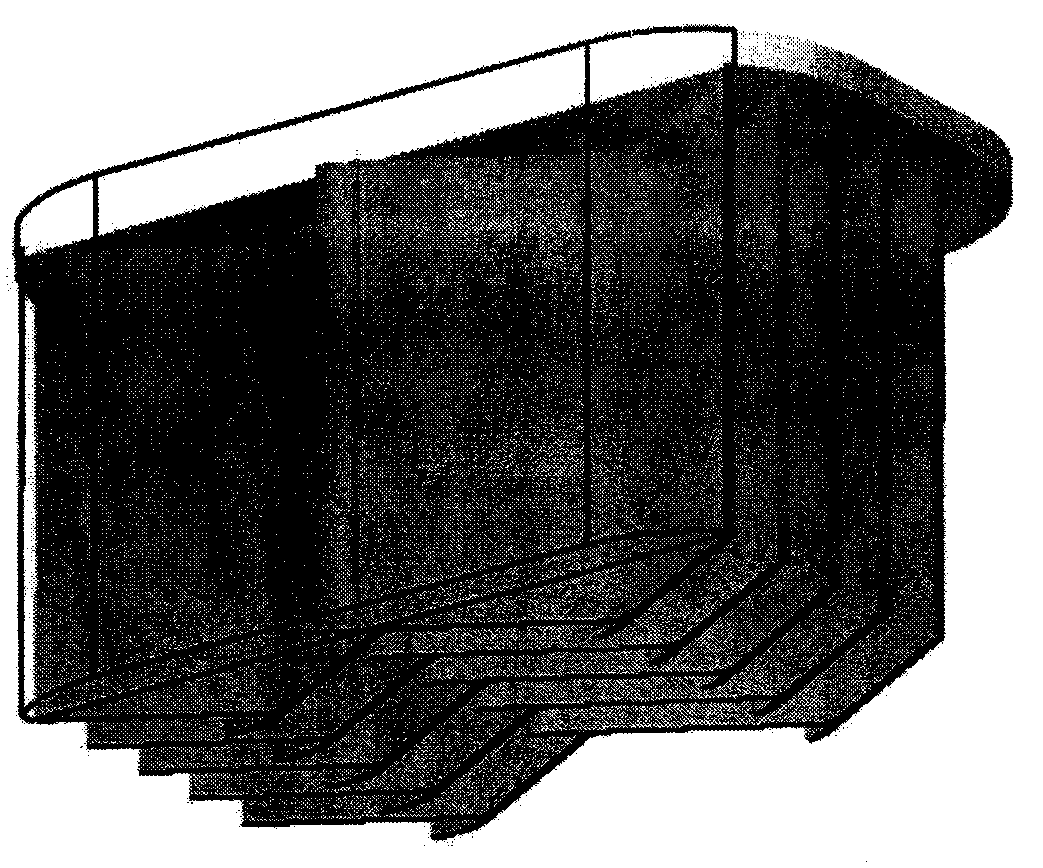

[0052] The waterfall water collector (13) is arranged above the sump (16), and the waterfall water collector (13) passes through the water pipeline and the pressurized water outlet (19), the booster pump (12) and the water storage ta...

Embodiment 2

[0075] The following is attached figure 1 , to illustrate a method for efficient heat exchange, water saving and demisting of wet cooling towers:

[0076] The fan (24) is running, and the outdoor air enters the inside of the cooling tower through the air inlet (5) under the action of the static pressure difference. The cooling water passes through the water distribution pipe (1) and passes through the atomizing nozzle (2). The reaction force formed when the 45° nozzle (26) sprays pushes the lower part of the nozzle (2) to rotate at a high speed, and most of the kinetic energy is converted into surface energy that promotes the atomization of the water flow when it hits the nozzle slope or passes through the gap, forming a wide range of atomization and spraying. Scattered water spray (3), the three-hole jet 45 ° nozzle (26) water spray in the center of the rotating head drives the fan blade (28) to rotate at a high speed, further strengthening the swirl effect of the water spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com