Reverse flow heat mass exchanging device with rain-free region

A heat and mass exchange, countercurrent technology, applied in heat exchanger types, lighting and heating equipment, direct contact heat exchangers, etc. Increase the overall shape coefficient of the unit to achieve high heat and mass exchange efficiency, improve heat and mass exchange efficiency, and good gas-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

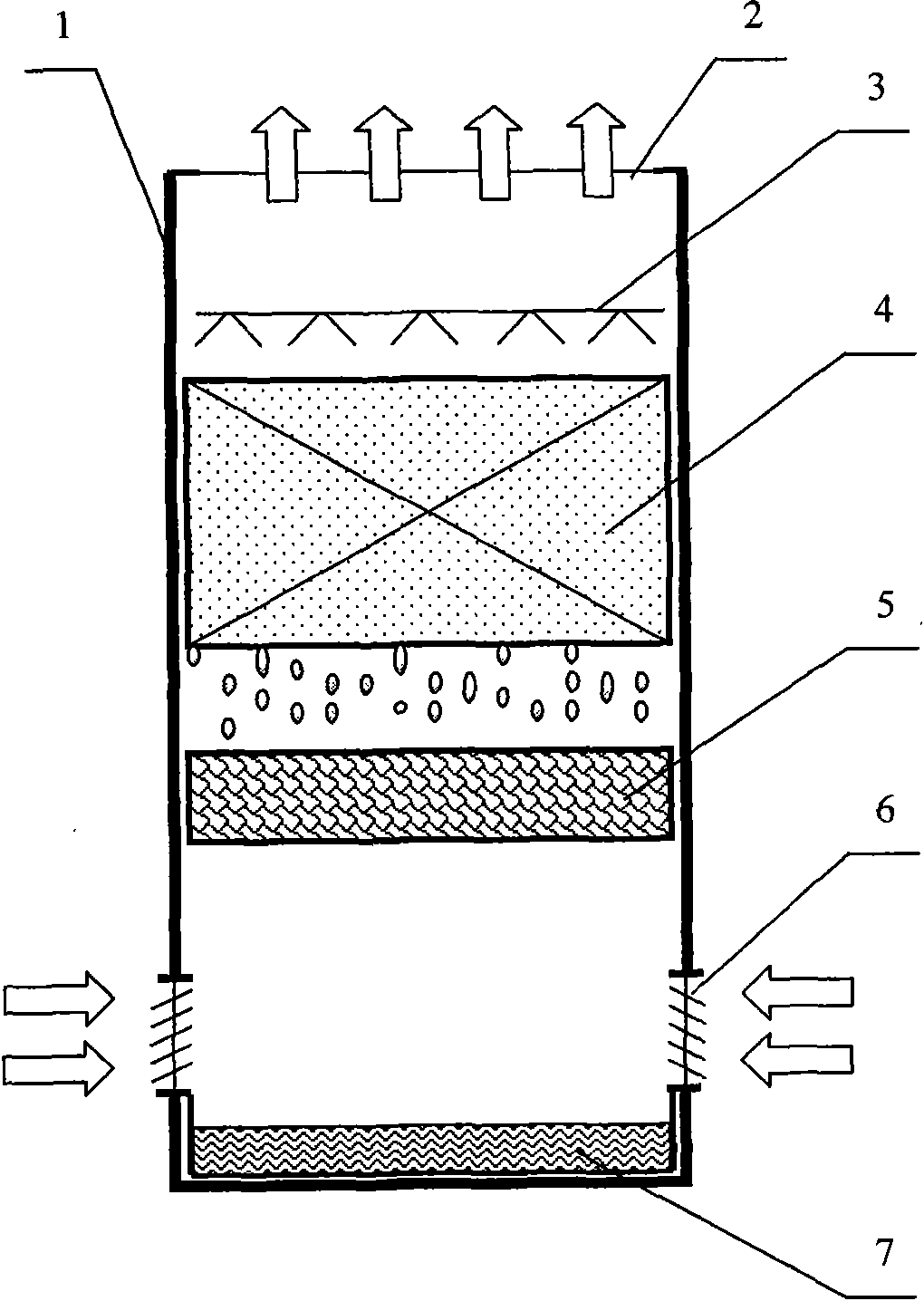

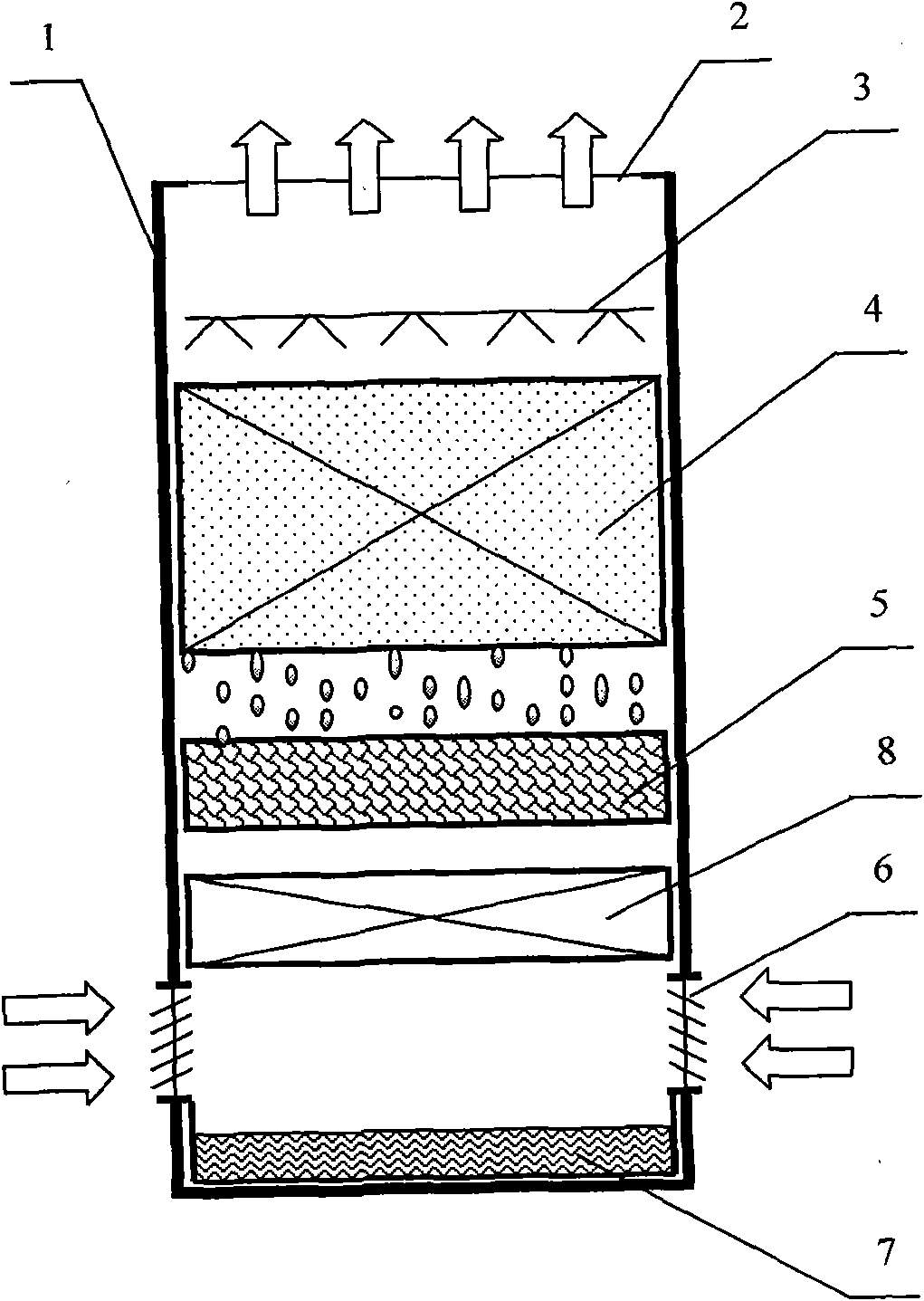

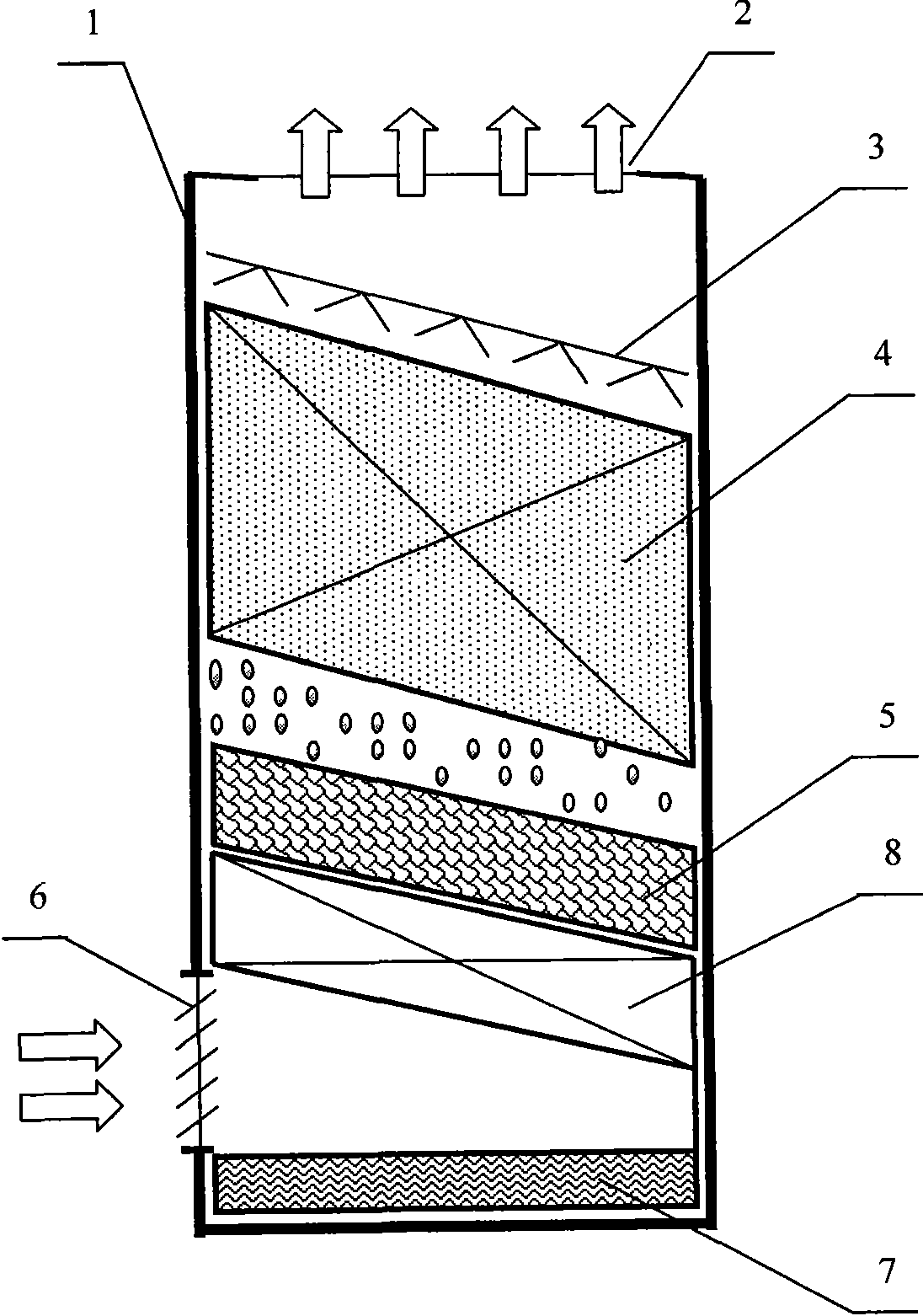

[0020] A counter-flow heat and mass exchange device with a rain-free zone, such as figure 1 As shown, the air outlet 2 is arranged on the top of the cabinet 1, the spray device 3 and the heat and mass exchange area 4 are sequentially arranged under the outlet 2, and the air inlet 6 is arranged on the bottom of the cabinet 1. 1 is provided with a water storage device 7, below the heat and mass exchange area 4, above the air inlet 6 is provided with a gas-liquid separation device 5 having an airflow channel and a water collection tank for collecting spray water, and the end of the gas-liquid separation device 5 water collection tank The water outlet hole is connected with water storage device 7. Such as figure 2 As shown, a surface cooler 8 is arranged below the gas-liquid separation device 5 . Such as image 3 As shown, the shape of the heat and mass exchange area 4 is a columnar body with a parallelogram at the bottom, wherein its four upright surfaces match the four walls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com