Corrosion proof heat and mass transfer device without carrying liquid and with solution for adjusting humidity

A liquid entrainment and exchange device technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of unspreading, metal corrosion, and entering the treated air, etc., to solve the problem of solution corrosion , high thermal conductivity, efficient dehumidification or regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

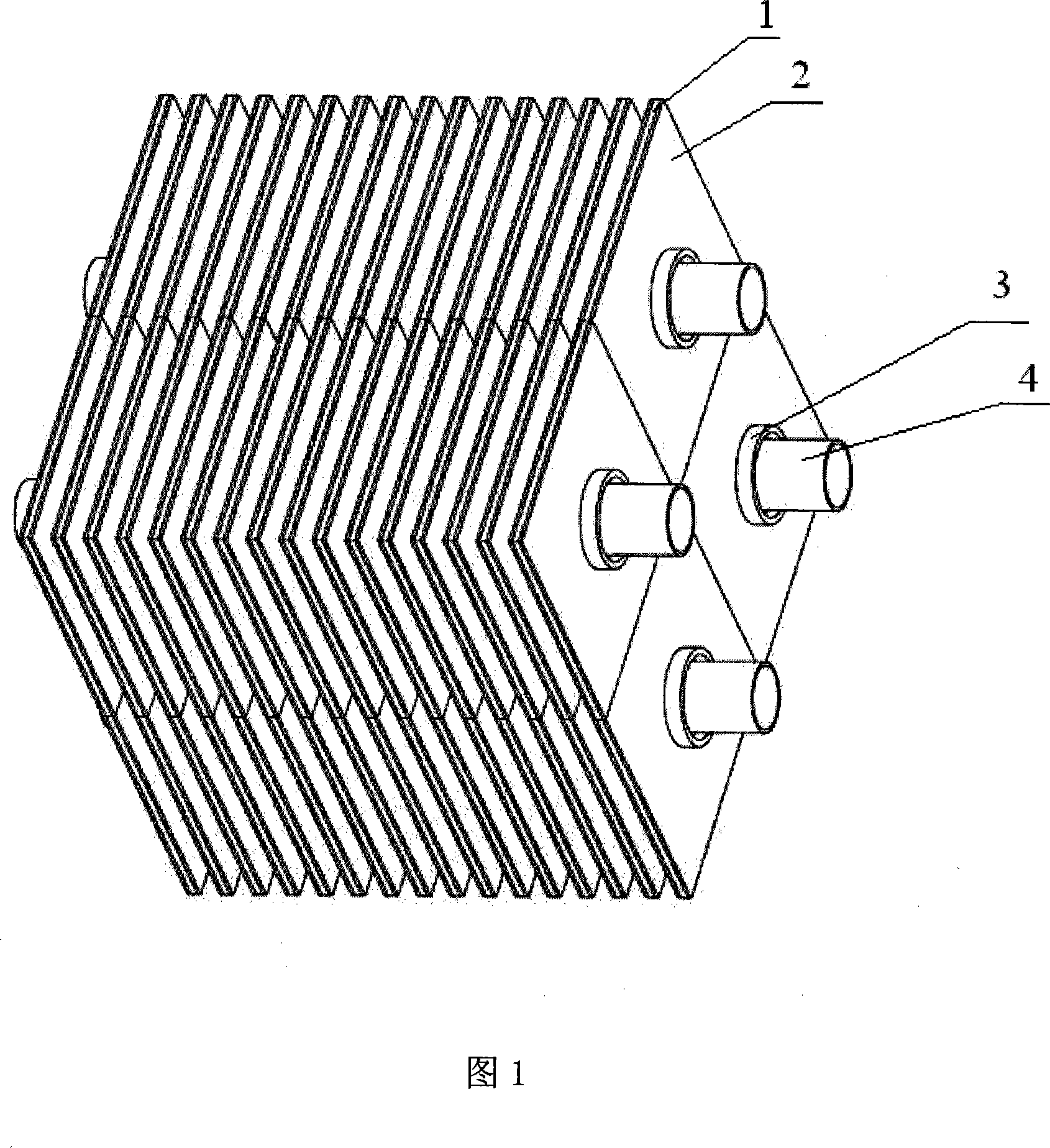

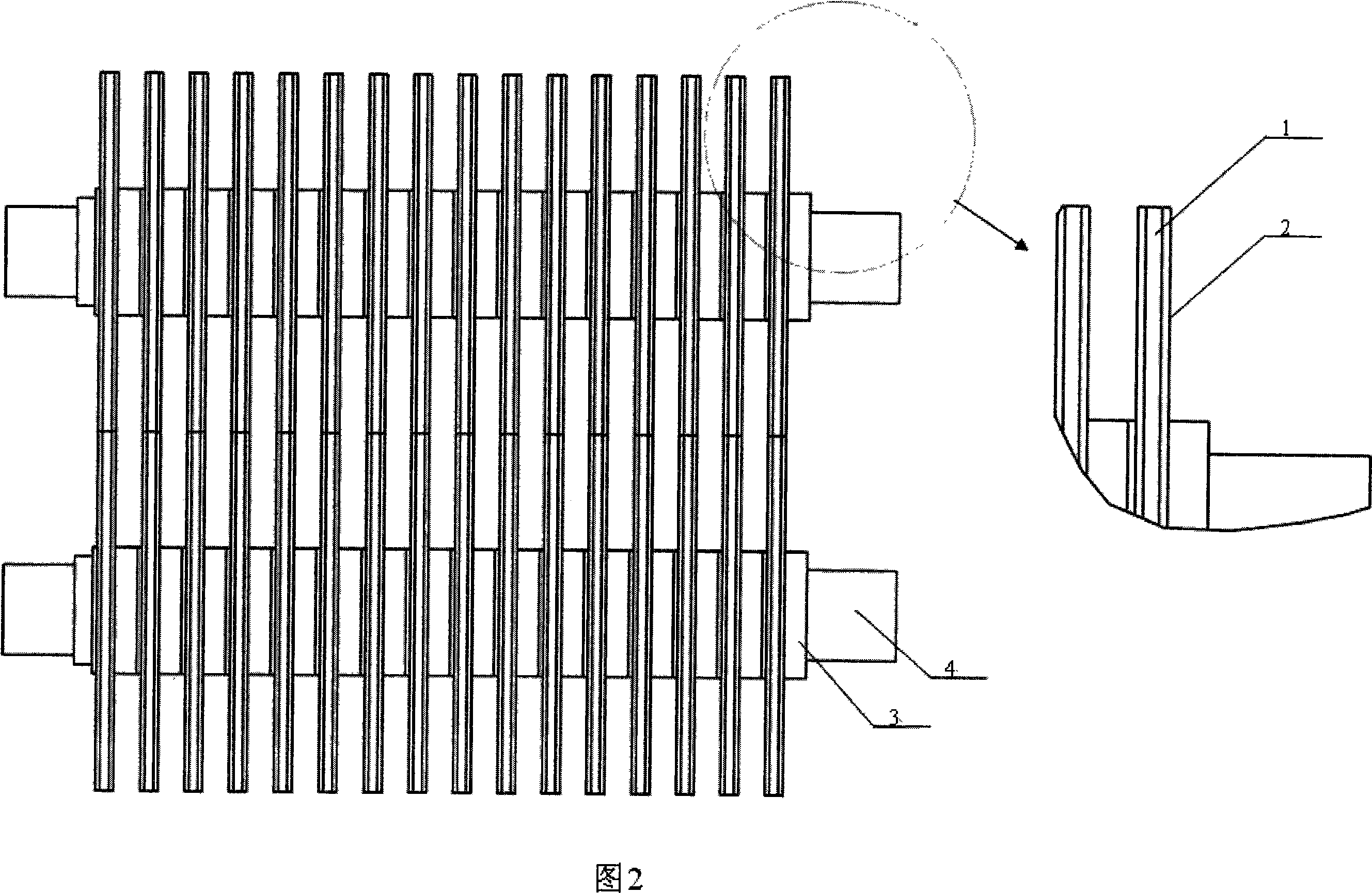

[0013] Figure 1 is an example of the present invention. The heat and mass exchange device is in the form of a finned tube heat exchanger, and the number of fins 1 is 16 along the direction of the base pipe 3 . The fins are rectangular in shape, arranged in two rows and two columns on a plane perpendicular to the base pipe 3 . The base pipe 3 is lined with a thin-walled copper pipe 4 . The material of the ribs 1 and the base pipe 3 is a high thermal conductivity plastic, and the base material of the high thermal conductivity plastic used is any one of polypropylene (PP), liquid crystal polymer (LCP) or polyphenylene sulfide (PPS), etc. The filler is at least one material selected from graphite, carbon fiber, heat-conducting ceramic powder, metal powder and metal oxide powder. The surface of the fin 1 is attached with a soaking material 2, and the soaking material 2 is paper, cotton cloth, linen cloth, polyester cotton cloth, acrylic cloth, polypropylene cloth or glass fiber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com