Method for improving ultrathin plasma silicon oxy nitride electrical test accurancy

A plasma and electrical testing technology, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problems of measurement time influence, EOT data inconsistency, curve non-linear, etc., to shorten the time and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the content of the present invention, the present invention will be further described below in conjunction with examples, but these examples do not limit the present invention.

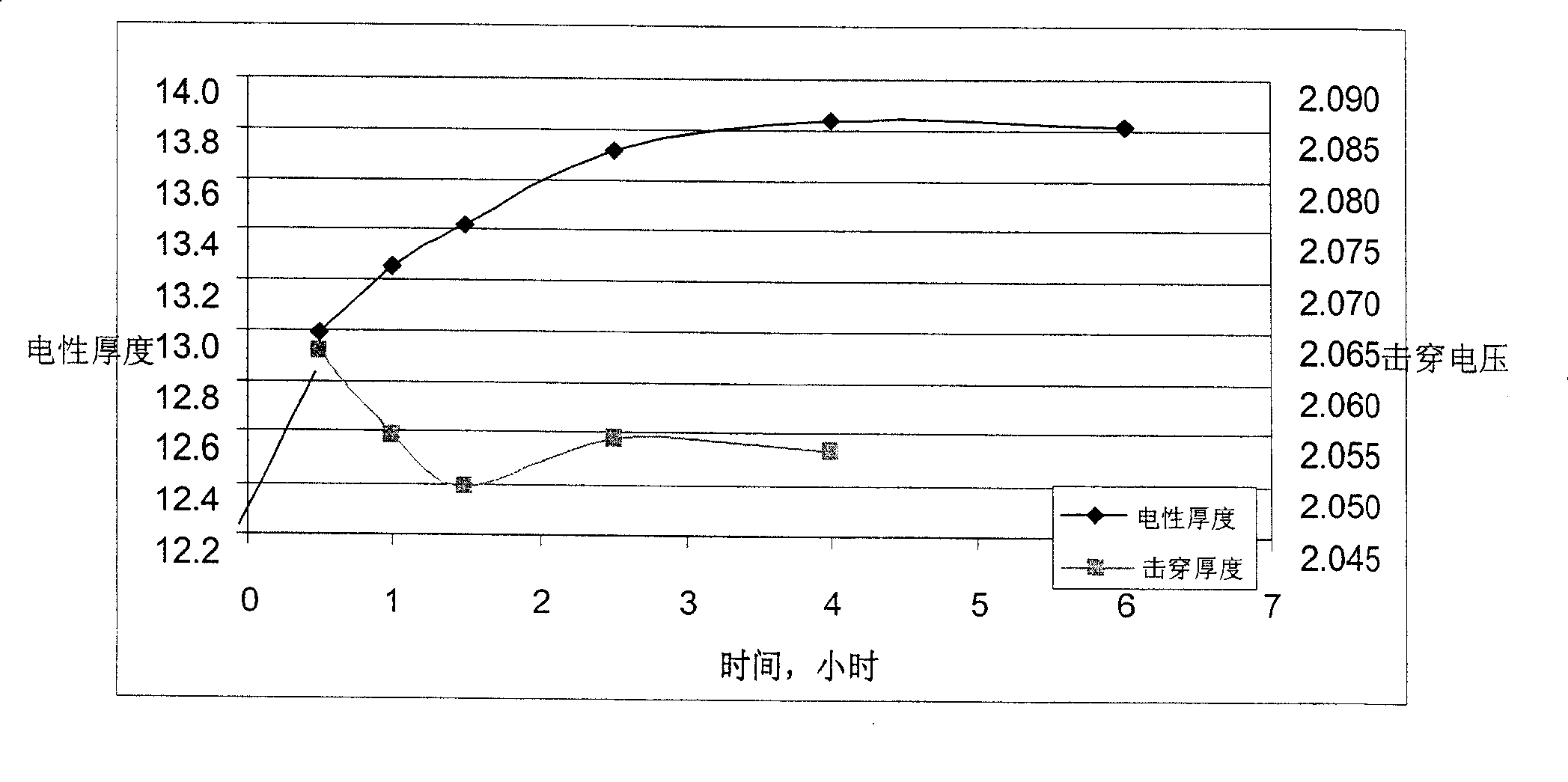

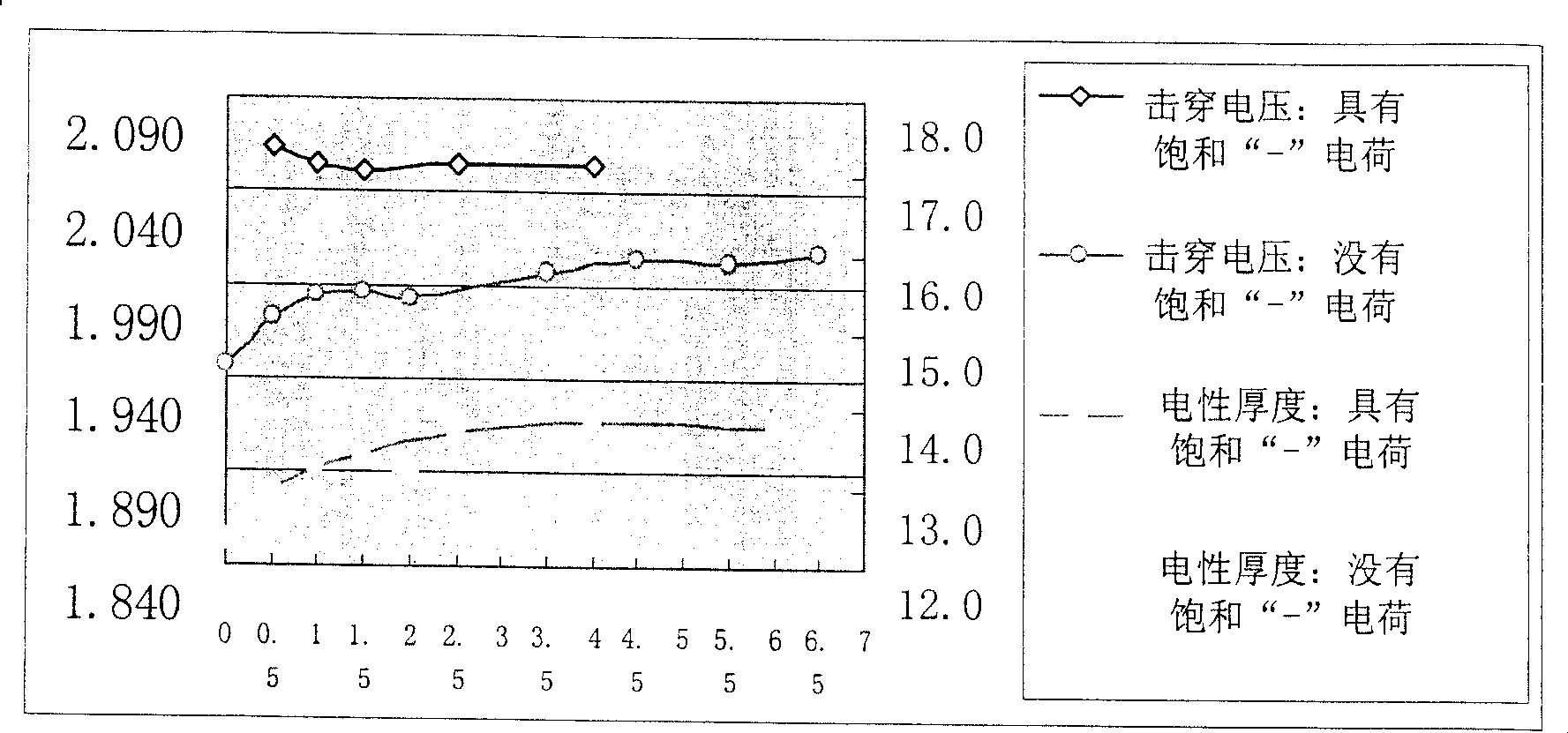

[0022] During the interval between obtaining the plasma nitrided oxide sample and waiting for the measurement, that is, before it is formally measured, the reverse charge is deposited on the surface of the sample comprehensively, and the deposited charge penetrates into the oxide surface for a period of time. and other charge neutralization in the object film. The sample can then be tested for corona charge using, for example, the Q-V method, without the test results being affected by excess unstable charges within the sample.

[0023] Wherein, the opposite charge can be deposited in such a way that an inert gas such as argon is ionized so that it has an electric charge opposite to that of the charge in the oxide film of the test sample, and the surface of the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com