A non-torsion chassis of motorcycle with four wheels

A technology of four-wheeled vehicles and motorcycles, which is applied to vehicle components, elastic suspensions, suspensions, etc., can solve the problems of low occupancy rate, waste of resources, and inability to meet consumption needs, and achieve reduced fuel consumption, less motion sickness, Simple structure and light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention and its advantages will be further described below in conjunction with the accompanying drawings and embodiments.

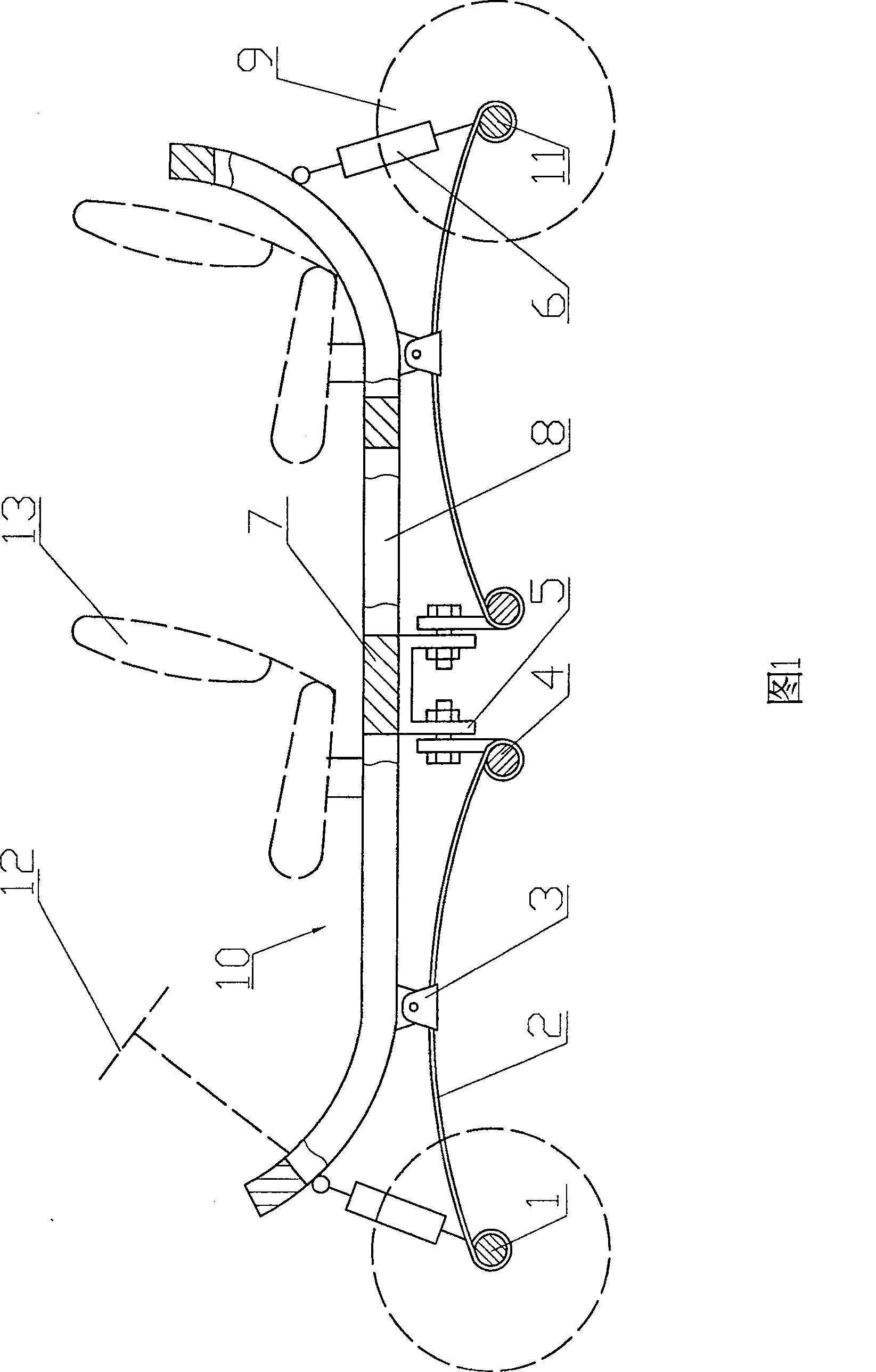

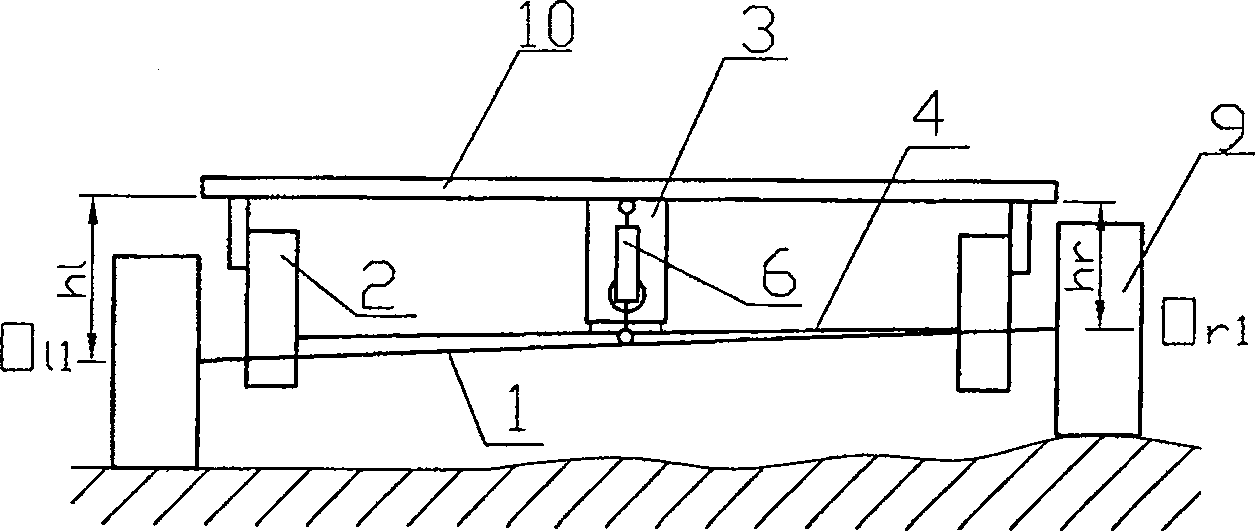

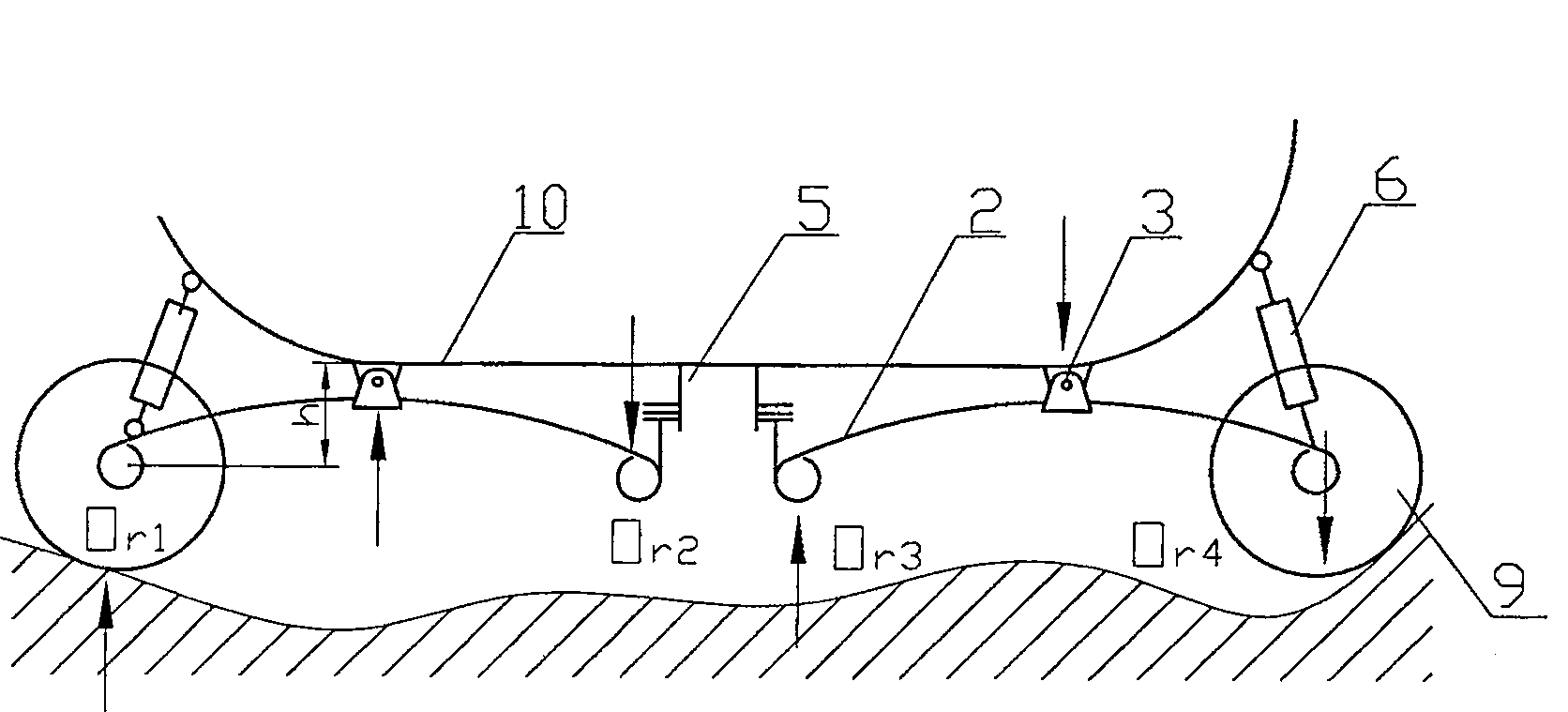

[0015] With reference to accompanying drawing 1, chassis of the present invention mainly is made up of bottom beam 10, wheel 9, leaf spring 2, damper 6, front axle 1, rear axle 11, lug 5, supporting frame 3 and transverse balance bar 4. The bottom beam 10 is welded by two parallel longitudinal beams 8 and four vertical beams 7 . Below the bottom beam 1 along its longitudinal two sides, that is, the lower side of the longitudinal beam 8 is equipped with two leaf springs 2 arranged in parallel. The placement of the leaf springs is just the opposite. The arch point in the middle part of the leaf spring is hinged with the longitudinal beam 8 through a support frame 3 . Corresponding two leaf springs 2 on the longitudinal beams on both sides of the bottom beam, the connecting bushings at the inner side are pierced by the end of a horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com