Device for taking out broken nail

A technology of extractor and broken nails, which is applied in the field of clinical medicine, can solve the problems of complex operation, long time, bone trauma, etc., and achieve the effect of short time consumption, small damage and less bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

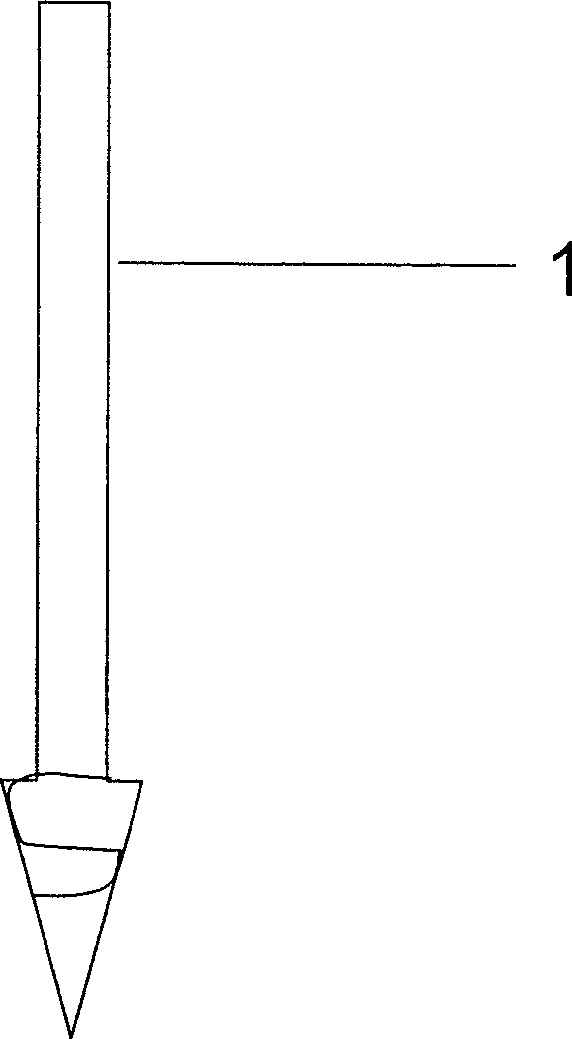

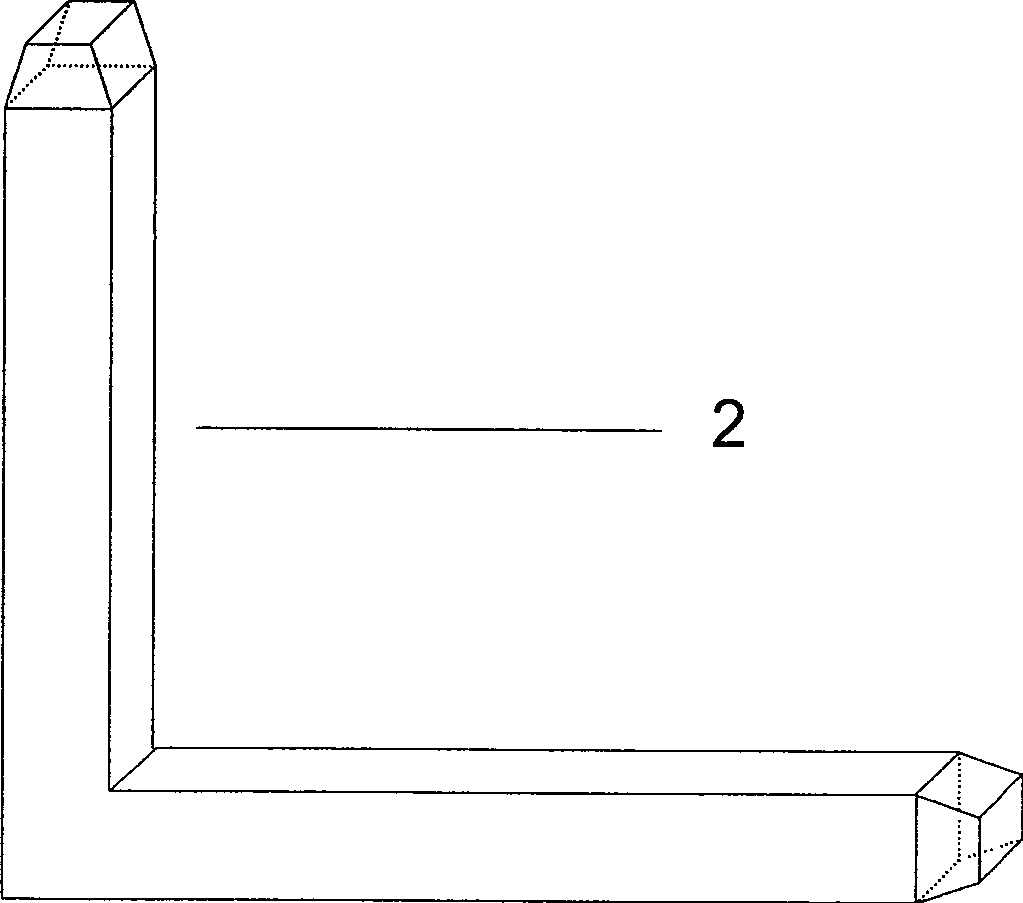

[0016] This example figure 2 Shown, be that a kind of steel column cross section is the nail breaker that takes a regular quadrilateral. Divided into two parts: drill bit 1 and nail breaker 2.

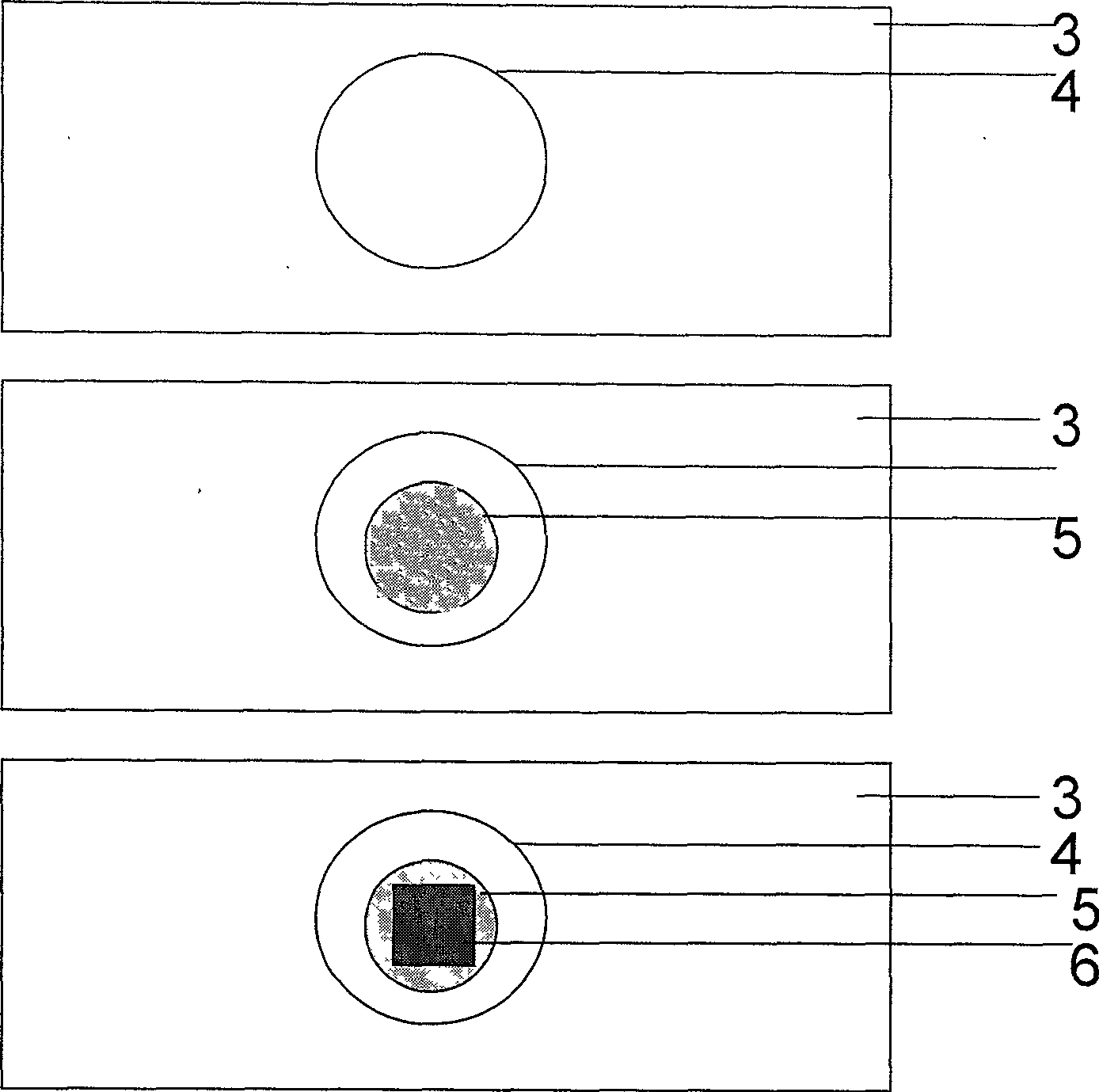

[0017] See attached figure 1 , figure 2 and image 3 , figure 1 and figure 2 It is a partial schematic diagram of the device of the present invention, which can be a series of products of different sizes to meet the needs of taking broken nails of different specifications. figure 1 Drill bit 1, high strength, can easily drill holes in the cross-section of broken nails after connecting to the electric drill; figure 2 It is to get the nail breaker 2, which is an L-shaped structure formed by connecting two cubic columns, and is made of high-strength steel. The diameter of the largest end of the drill bit is 0.1 to 0.3 mm larger than the diameter of the circumscribed circle of the cubic column nail breaker, that is, the diameter of the circumscribed circle of the cubic column to...

Embodiment 2

[0020] The nail breaker is an L-shaped structure, connected by two regular triangular columns, and made of high-strength steel. It can be a series of products of different sizes to meet the needs of different specifications of broken nails. Drill bit 1, high-strength, can easily drill holes in the cross-section of broken nails after connecting with an electric drill. The diameter of the largest end of the drill bit is 0.1 to 0.3 mm larger than the circumscribed circle diameter of the regular triangular column to take the nail breaker, that is, the circumscribed circle of the regular triangular column to take the nail breaker The diameter is 0.1 to 0.3 mm smaller than the diameter of the largest end of the drill bit. The end of the L-shaped structure of the nail breaker gradually decreases from 5 mm to the end to form a trapezoid on the side, and a regular triangle pyramid at the upper and lower bases. The difference between the upper and lower bases of the trapezoid on the sid...

Embodiment 3

[0023] The nail breaker is an L-shaped structure, connected by two regular pentagonal columns, and made of high-strength steel. It can be a series of products of different sizes to meet the needs of different specifications of broken nails. Drill bit 1, high-strength, can easily drill a hole in the cross-section of the broken nail after connecting the electric drill. The diameter of the largest end of the drill bit is 0.1-0.3 mm larger than the diameter of the circumscribed circle of the regular pentagonal nail breaker, that is, the regular pentagonal column is broken The diameter of the circumscribed circle of the nailer is 0.1 to 0.3 mm smaller than the diameter of the largest end of the drill bit. The end of the L-shaped structure of the nail breaker gradually decreases from 5 mm to the end to form a trapezoidal pyramid on the side, and the difference between the upper and lower bases of the trapezoid on the side is 0.2 to 0.4 mm.

[0024] The method of use is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com