Pneumatic tire

A technology for pneumatic tires and tires, applied to the reinforcement layer of pneumatic tires, tire parts, wheels, etc., can solve the problem that the reverse "V" bending deformation cannot be fully suppressed, and achieve the effect of preventing bending phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

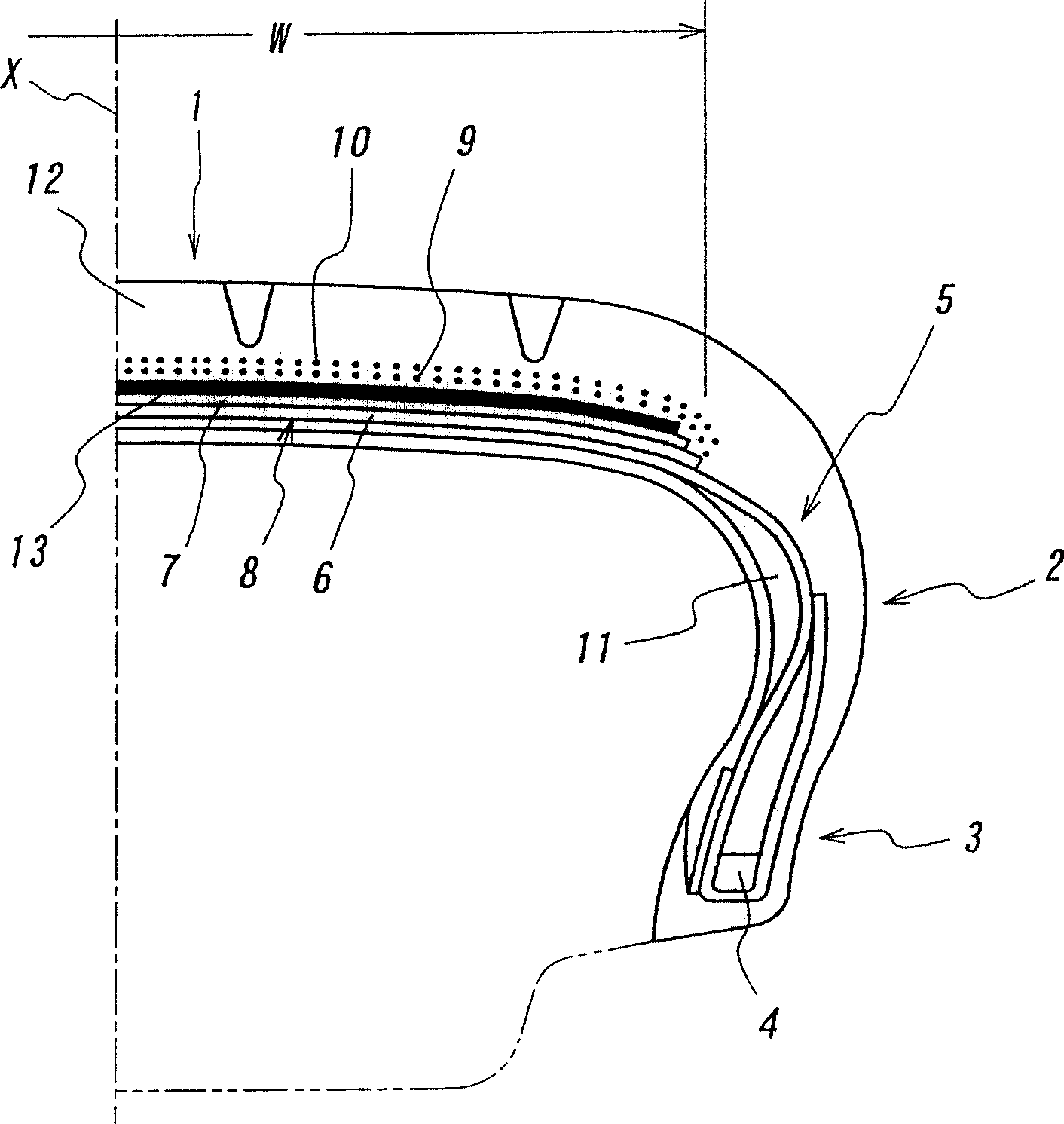

[0044] The size of each tire in the embodiment and the comparative example is 245 / 40R18, and has the structure shown in Figure 2, and the dimensions are shown in Table 1, wherein the rubber reinforcement layer made of low-loss, high-rigidity rubber has the largest The thickness is 8mm, the two-layer cover is made of nylon fiber rope, the width of the inner belt layer is 200mm, the width of the outer belt layer is 190mm, and the width of the additional belt layer is 180mm. They are installed in a 18×8JJ Rigid ring (rim), and when the inflation pressure is 230kPa or 0kPa, test its driving stability on icy roads and the amount of tread rise when the internal pressure is reduced, or when the internal pressure of the tire is 0kPa and the load is 4.81 When kN and speed are 89km / h, the run-flat durability of running 200km without any problem is tested. The test results are shown in Table 1.

[0045] In Table 1, the bulk modulus of the tread rubber is calculated from the relationship ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap