Power car wheel pair gear box side disk-braking press mounting technology

A gearbox and brake disc technology, which is applied in the manufacture of tools, metal processing, metal processing equipment, etc., can solve the problem that the brake disc cannot be press-fitted on the side of the gear box by the moving wheel, and achieve the effect of ensuring the press-fit efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

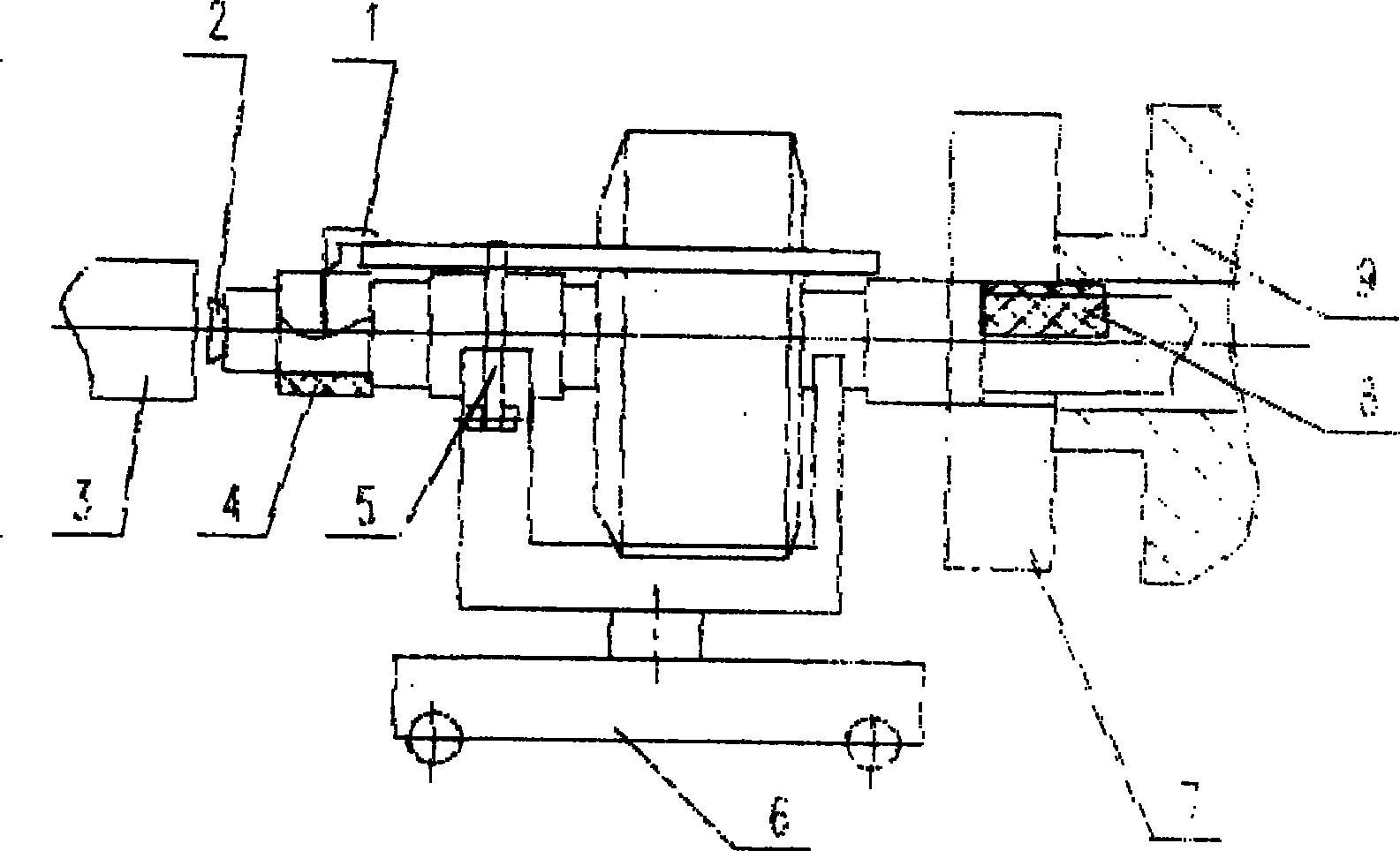

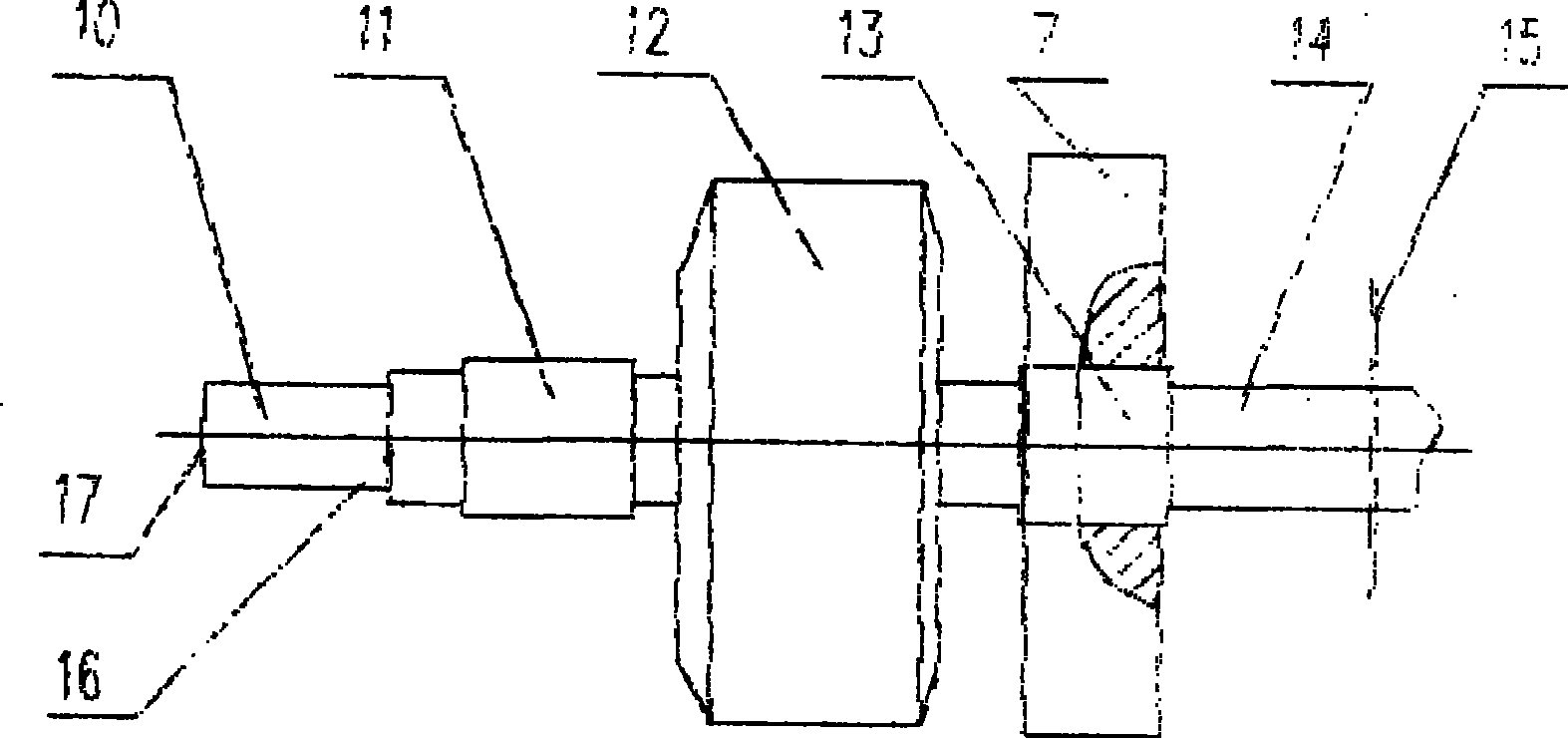

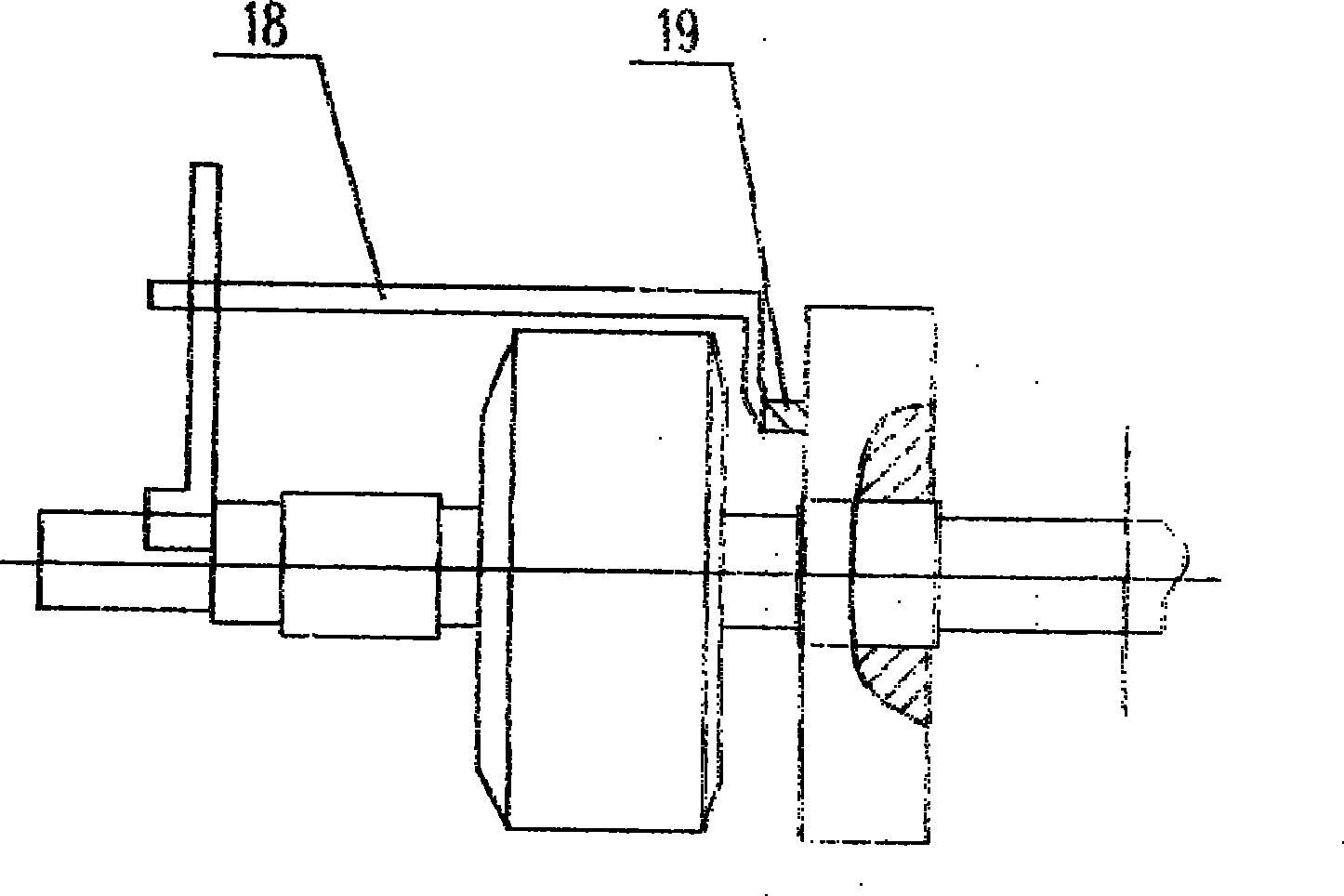

[0017] 1. At first, on the axle shaft body 14 of the motor car belt gearbox (see figure 2 ) on the semi-transitional nylon sleeve 8 (see figure 1 ), and the brake disc 7 is pre-installed on the semi-transition nylon sleeve 8. After the semi-transitional nylon sleeve 8 is placed on the shaft body 14, its outer diameter should be about 0.3mm smaller than the outer diameter of the disc seat, which can ensure that the brake disc hole and the axle disc seat are well aligned to prevent any damage caused during the press-fitting process. Axle accident.

[0018] 2. Install the above components and hang them on the mobile rotating bracket 6 for pressing (see figure 1 ), lock the axle wheel seat 11 (see figure 2 ) at the locking mechanism 5 to prevent tipping. And ensure that the center of the axle shaft is substantially consistent and level with the center of the press by adjusting the height of the mobile swivel support 6 .

[0019] 3. Insert the positioning nylon sleeve 4 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com