Fruit size compensation method and apparatus for light characteristic on-line detection of fruit internal quality

A compensation device, internal quality technology, applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve problems affecting detection accuracy, detection accuracy and detection speed need to be improved, large detection errors, etc. Achieve the effect of improving detection accuracy and improving the automation level of online non-destructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] The design of the fruit size compensation device in the fruit online detection device is as follows: Figure 1 to Figure 8 Described.

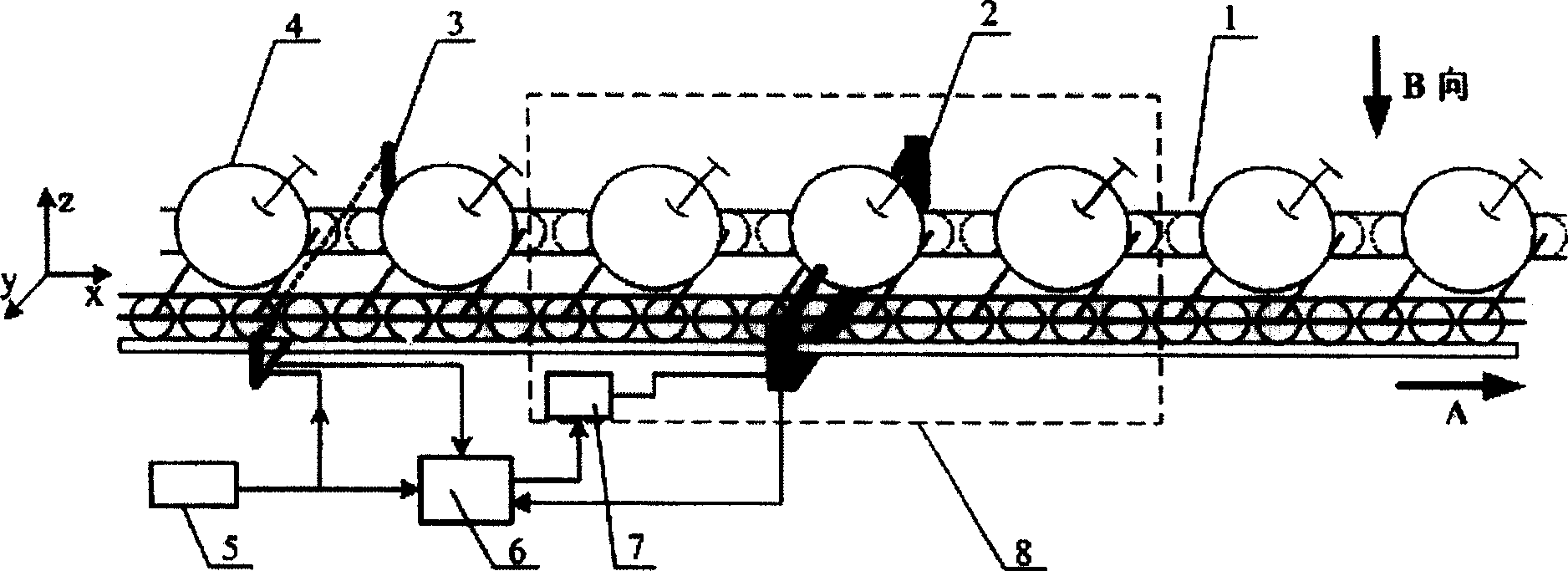

[0037] Such as figure 1 As shown, the size compensation device is composed of a conveying unit 1, a size compensation unit 2, a size detection unit 3, an encoder 5, a control unit 6, a drive unit 7 and the like.

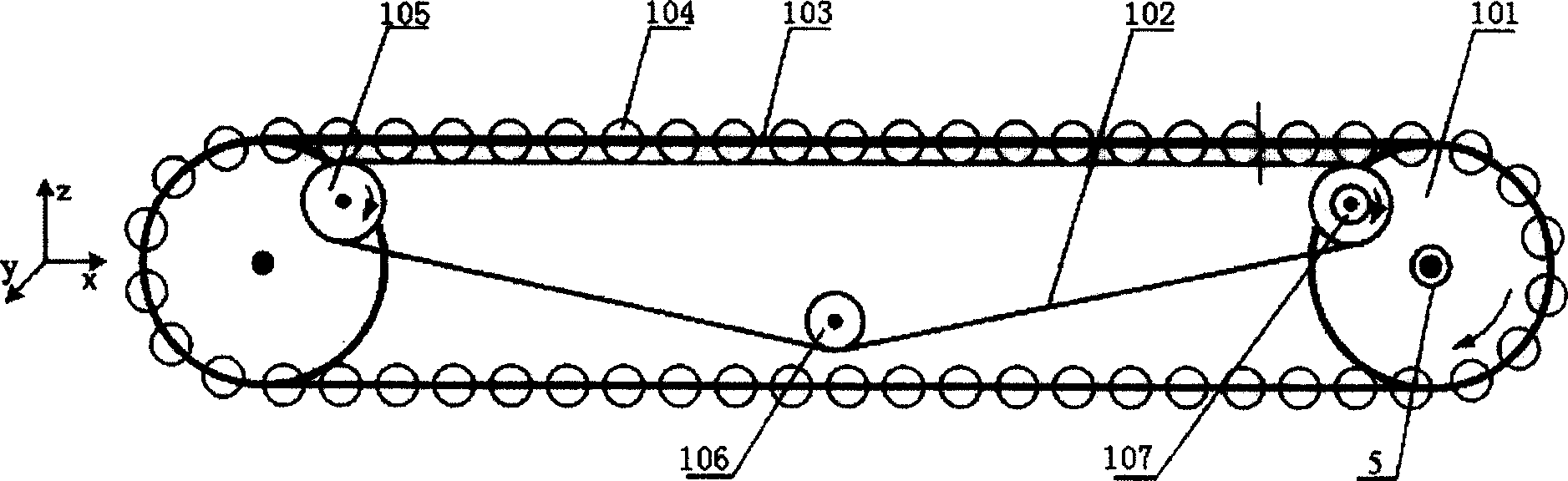

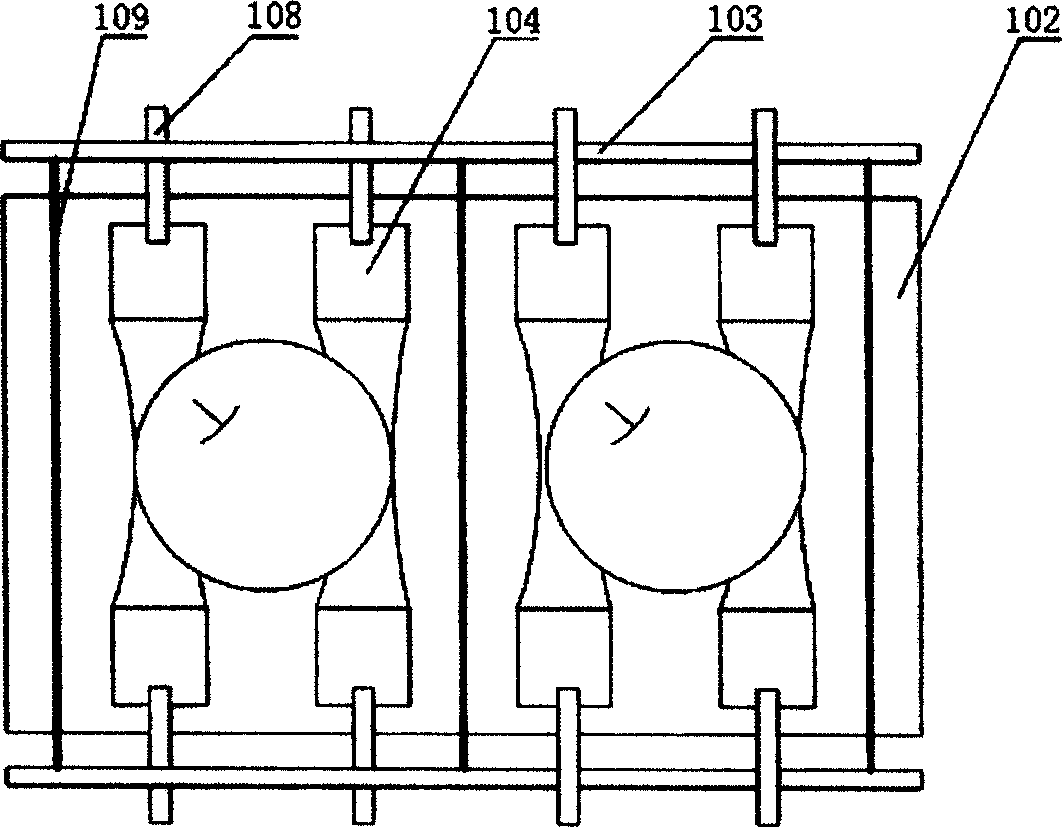

[0038] Such as figure 2 , image 3 As shown, the conveying unit includes a driving sprocket 101 , a friction belt 102 , a chain 103 , a roller 104 , a friction belt pulley 105 , a tensioning wheel 106 , a speed regulating motor 107 , a small shaft 108 and a supporting connection frame 109 .

[0039] The chain 103 surrounds the two driving sprockets 101, and there is a support connecting frame 109 between the two chains to form the skeleton structure of the conveyor belt; the roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com