High-precision optical spherical cover and mould, and making process thereof

A production process, high-precision technology, applied in optics, television, instruments, etc., can solve the problems of low picture accuracy, unclear images, affecting the image quality of cameras, and achieve high picture accuracy, clear images, and finished products. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below

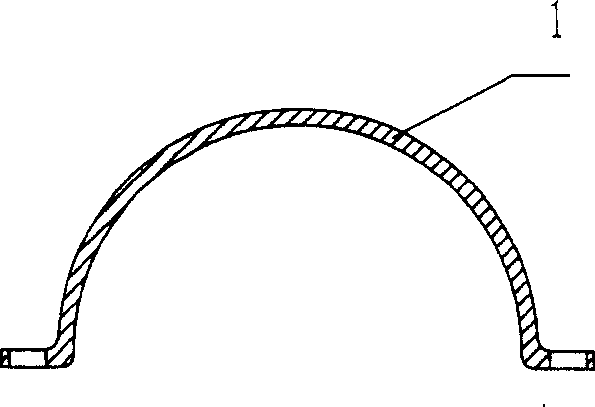

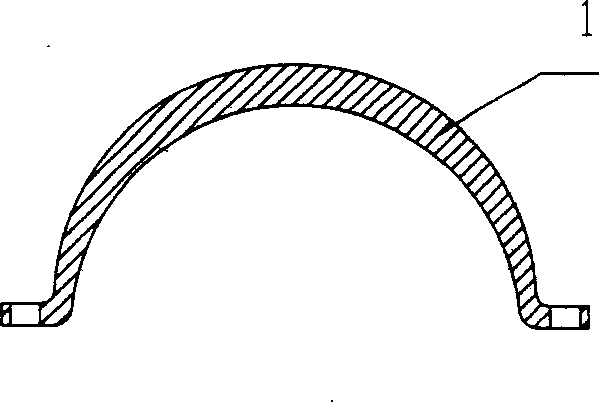

[0029] Such as figure 2 As shown, a high-precision optical dome cover is shaped as a hemispherical shell. The inner and outer surfaces of the shell are coaxial and not concentric. The center of the outer surface is higher than the center of the inner surface, forming thin, For the thick shell in the middle, the distance between the center of the outer surface of the shell and the center of the inner surface of the shell is 10--60 μm, and a variety of frames can also be provided for matching.

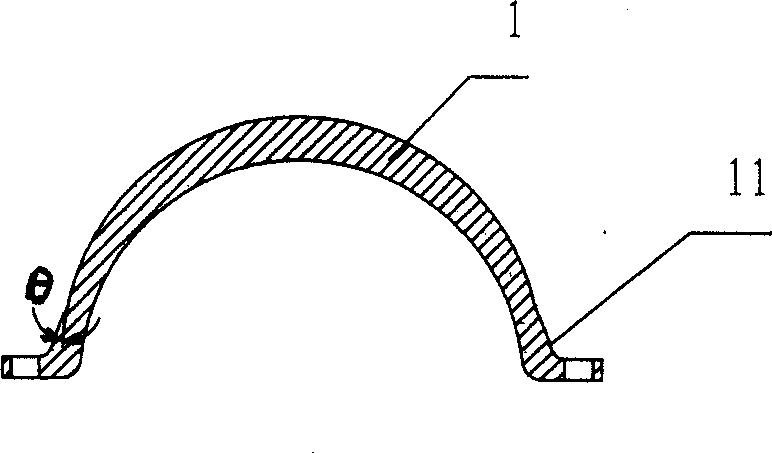

[0030] Such as image 3 As shown, there is a conical arc surface 11 with a radius greater than the radius of the outer surface on the edge of the outer surface of the dome cover 1, and the included angle θ between the conical arc surface 11 and the outer surface is 2-7 degrees, preferably 3-5 degrees , and the rest are the same as the above example.

[0031] A spherical shell with different thicknesses is formed by two spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com