Bainite steel rail with excellent anti-fatigue performance and its production method

A production method and anti-fatigue technology, applied in the field of iron and steel materials, can solve the problems of aggravating non-metallic inclusions, residual stress, austenite instability, bainite rail fatigue performance, etc., achieve excellent fatigue resistance, change the structure and performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

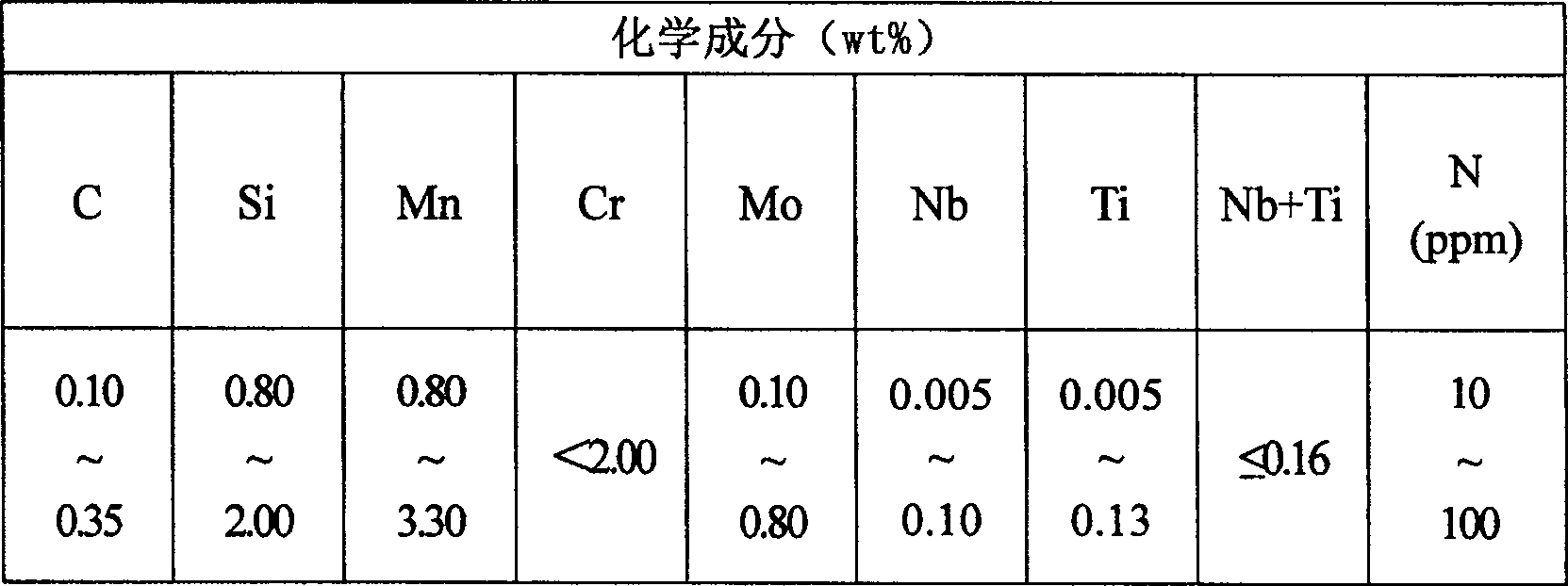

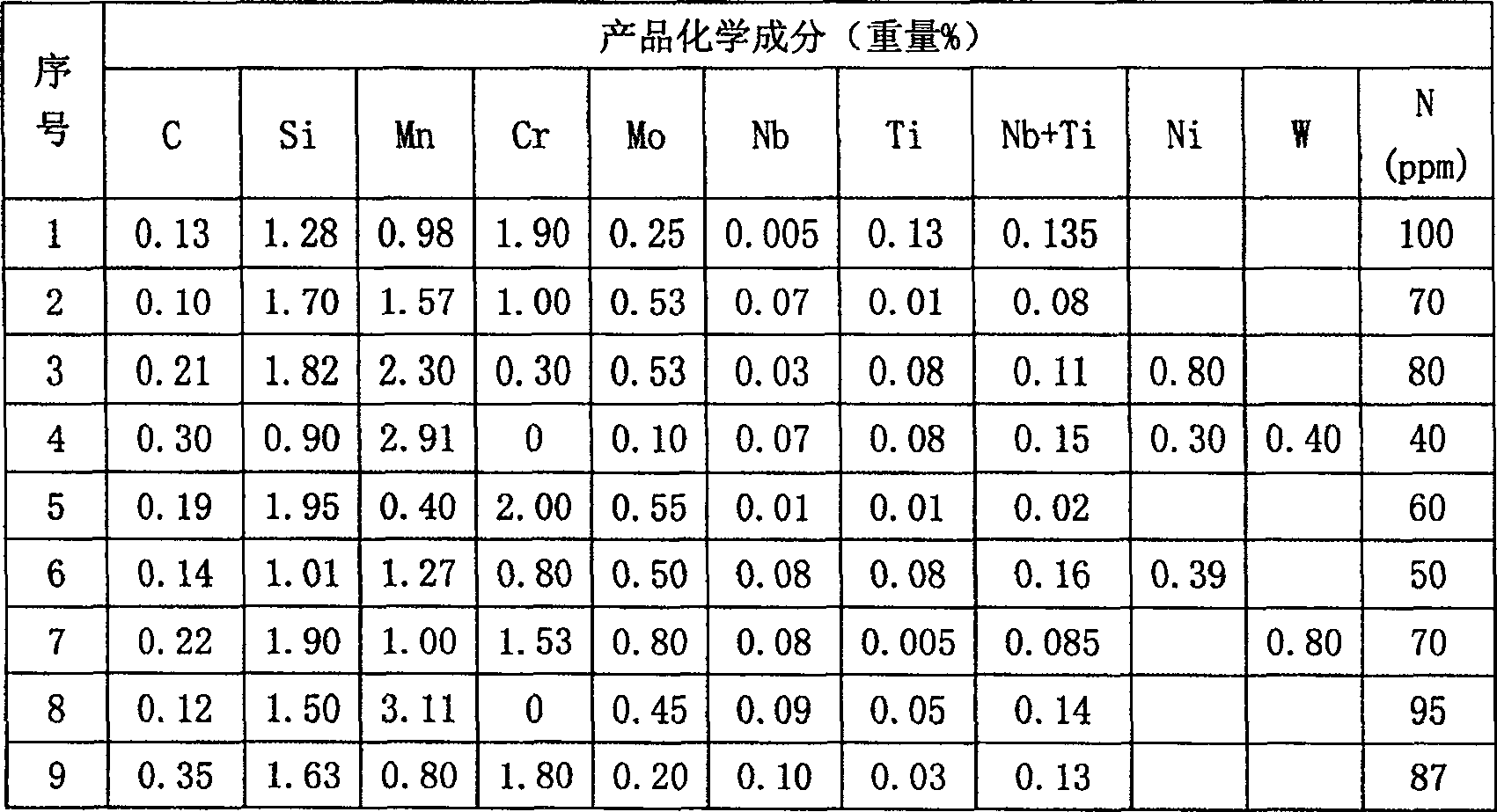

[0022] The chemical composition of the present invention is calculated by weight percentage, containing C: 0.10-0.35%, Si: 0.80-2.00%, Mn: 0.80-3.30%, Cr: <2.00%, Mo: 0.05-0.80%, N: 10 ~100ppm, add Nb and Ti in combination, Nb: 0.005~0.10%, Ti: 0.005~0.13%, and Nb+Ti≤0.16, H≤1.0ppm, the rest is Fe and unavoidable impurities.

[0023] The present invention can also add one of Ni and W to the above-mentioned rail components as required or in different combinations, wherein Ni: ≤0.8%, W: ≤0.8%. Adding Ni and W is used to further improve the stability of retained austenite. The effect of adding Nb or V or Ti or Nb, V or V and Ti combined addition alone is not as good as Nb and Ti combined addition. The method of compound addition of Nb and Ti makes the microstructure of the rail very fine, and has the microstructure conditions required for canceling the tempering of the rail.

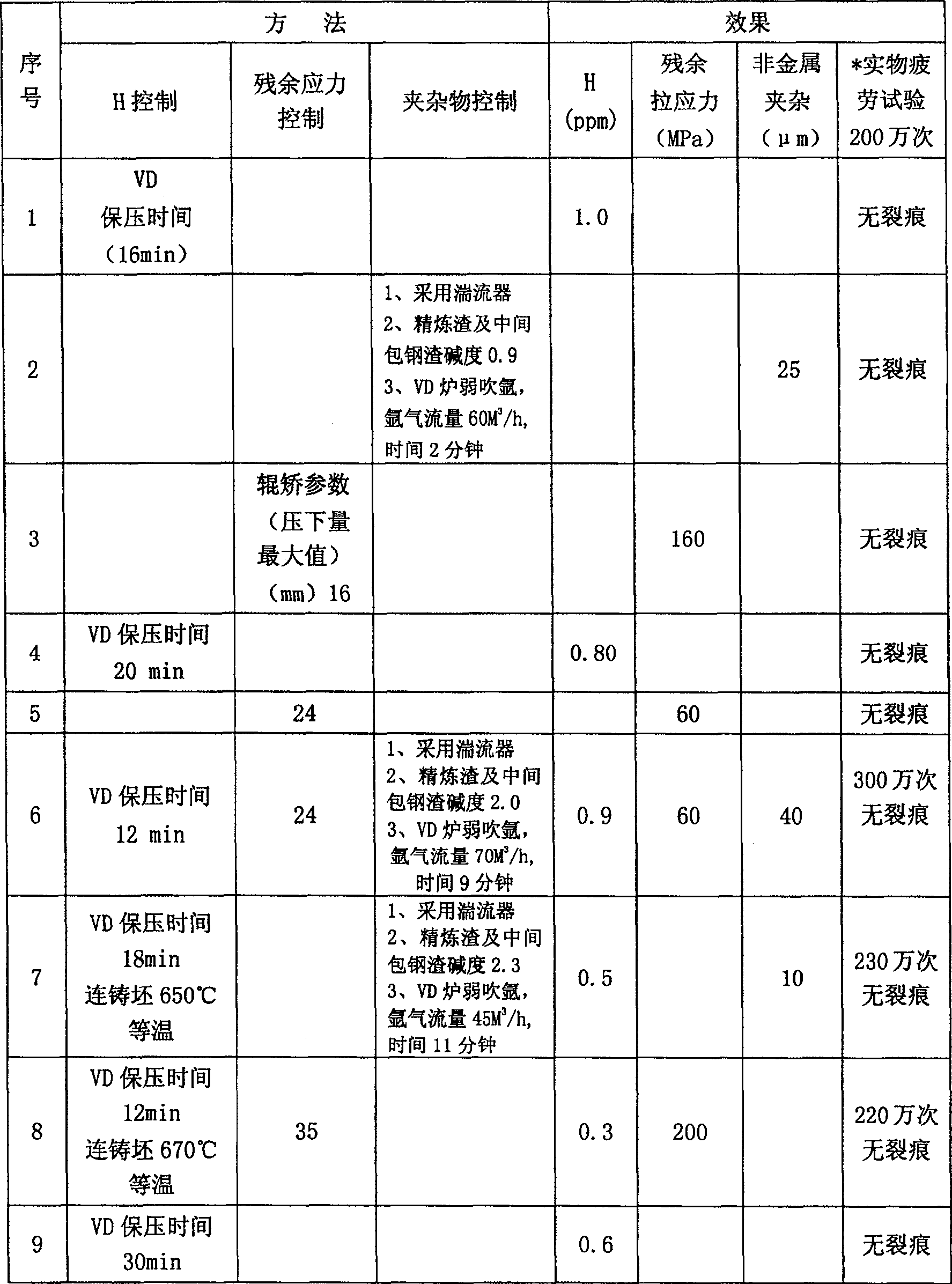

[0024] In order to obtain the above-mentioned properties, the present invention controls its chemical c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com