Assembly type nozzle diaphragm, and method of assembling the same

A technology of nozzle baffles and baffles, which is applied in engine manufacturing, machine/engine, stator, etc., can solve problems such as difficult cost reduction, welding cost reduction, and difficult automatic welding, so as to achieve high turbine classification efficiency and reduce the cost of replacement operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

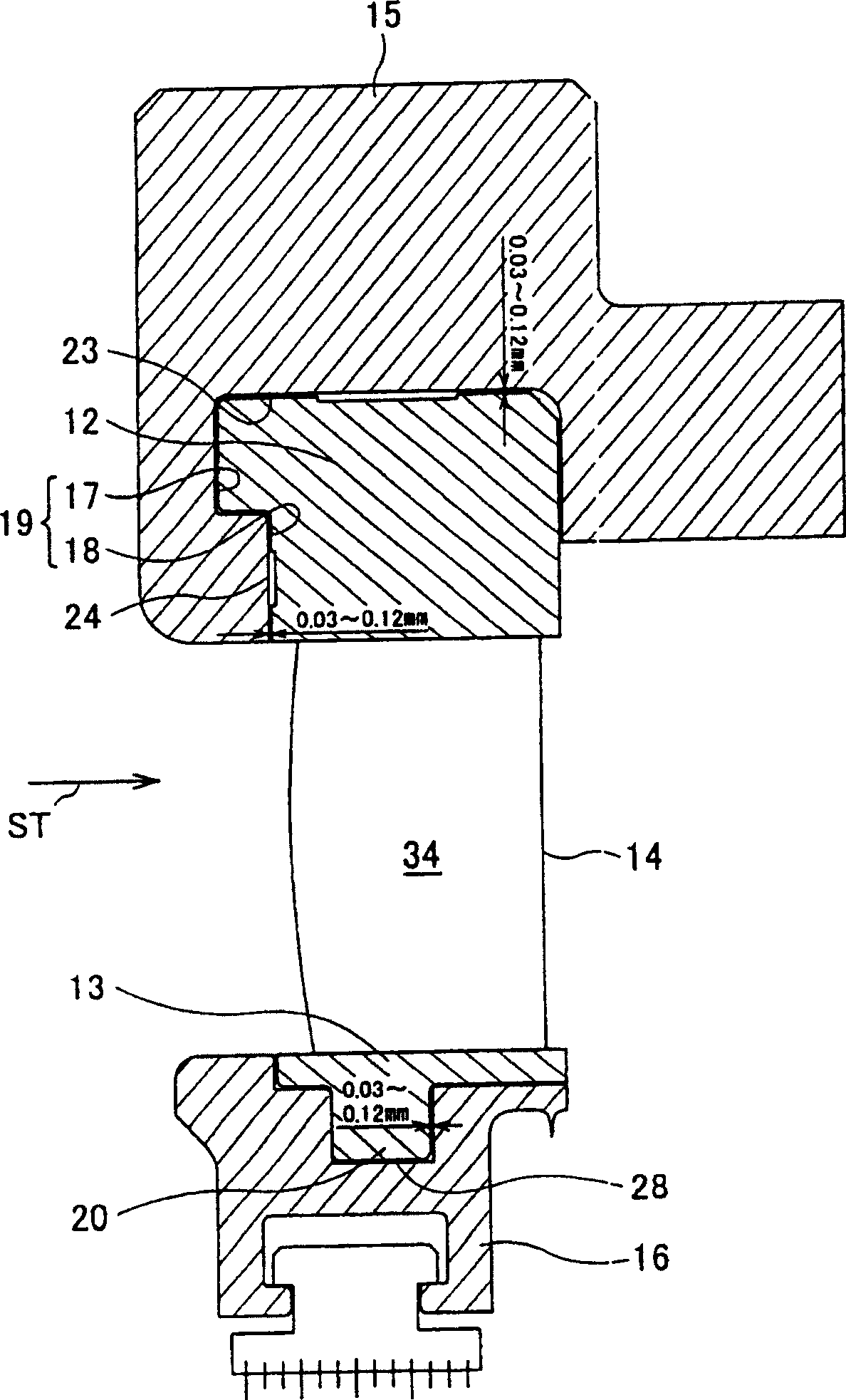

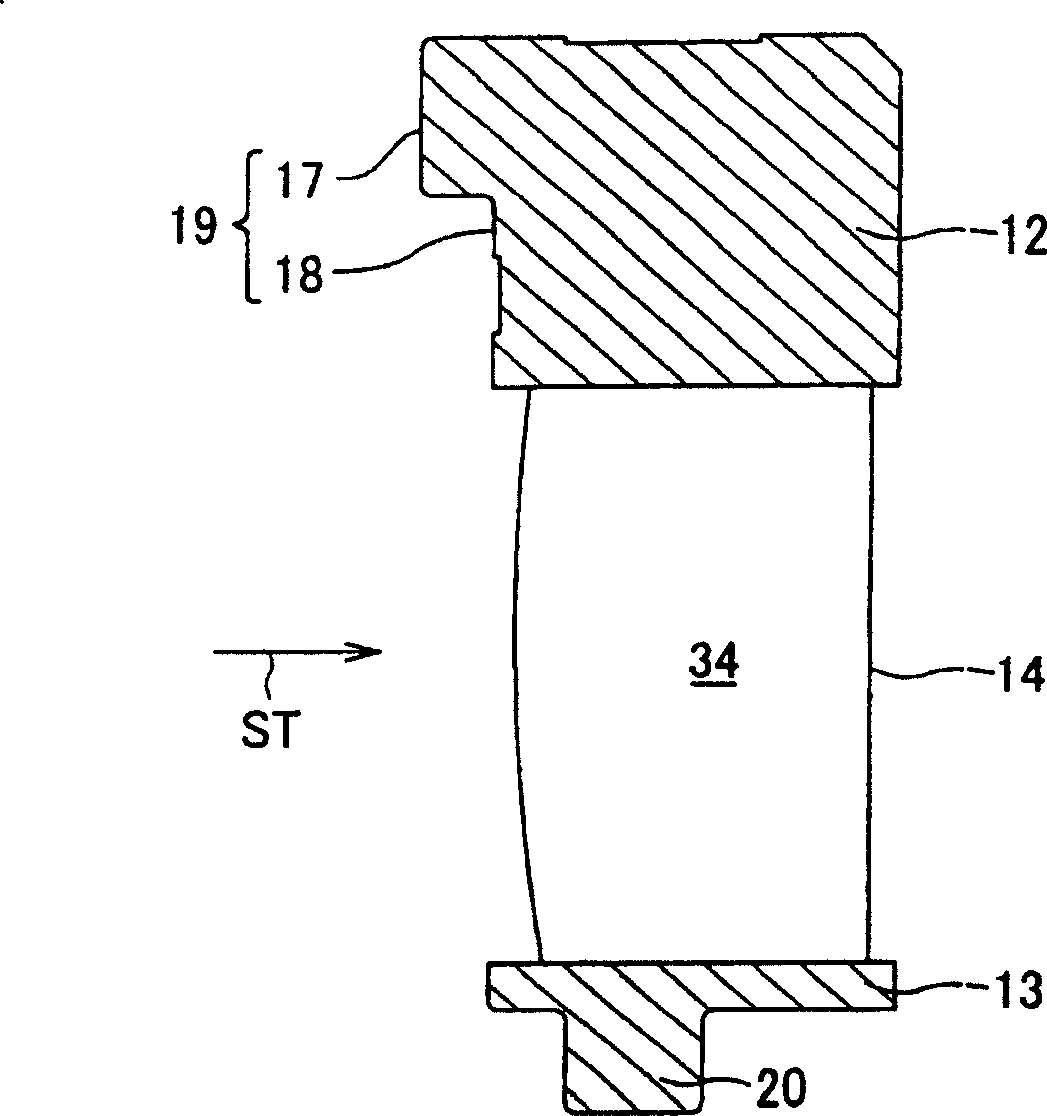

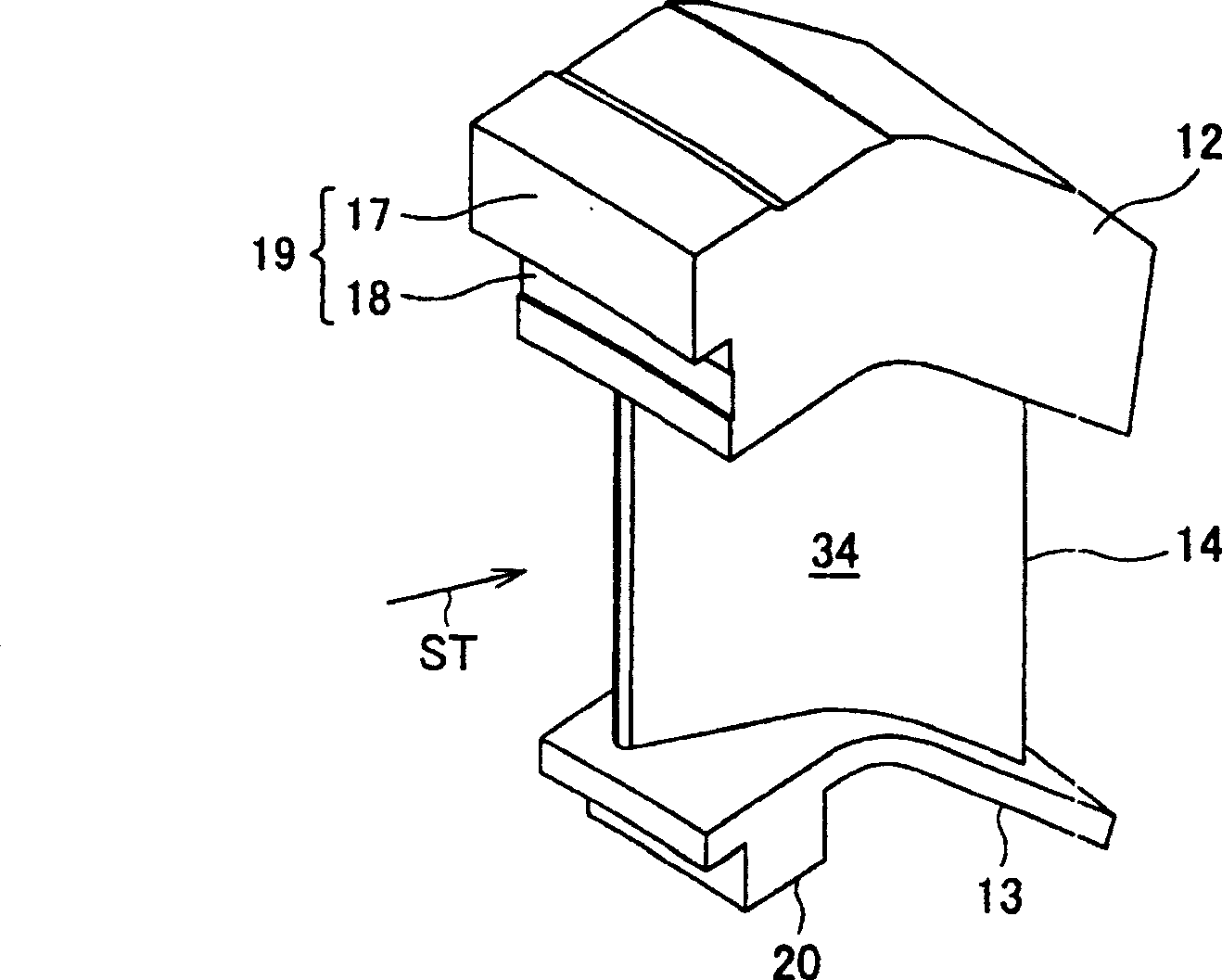

[0075] Embodiments of the assembly type nozzle diaphragm and assembly method of the present invention will be described below by reference numerals attached to the drawings and with reference to the drawings. In various embodiments, fabricated nozzle diaphragms are employed in steam turbines. The reference ST in the figure represents the steam flow inside the steam turbine.

[0076] Figure 31 shows multiple stages of an axial flow steam turbine 100 with fabricated nozzle baffles. Each nozzle vane 104 is connected to the diaphragm outer ring 102 and the diaphragm inner ring 103 , wherein the diaphragm outer ring 102 is connected to the turbine casing 101 , thereby forming nozzle vane flow passages. A plurality of turbine moving (rotor) vanes 106 are arranged downstream of the nozzle vane flow path. The moving blades 106 are built or fitted on the outer periphery of the rotor wheel 105 at predetermined intervals in the circumferential direction, and a cover 107 for preventing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com