Chemical-mechanical polishing equipment and process

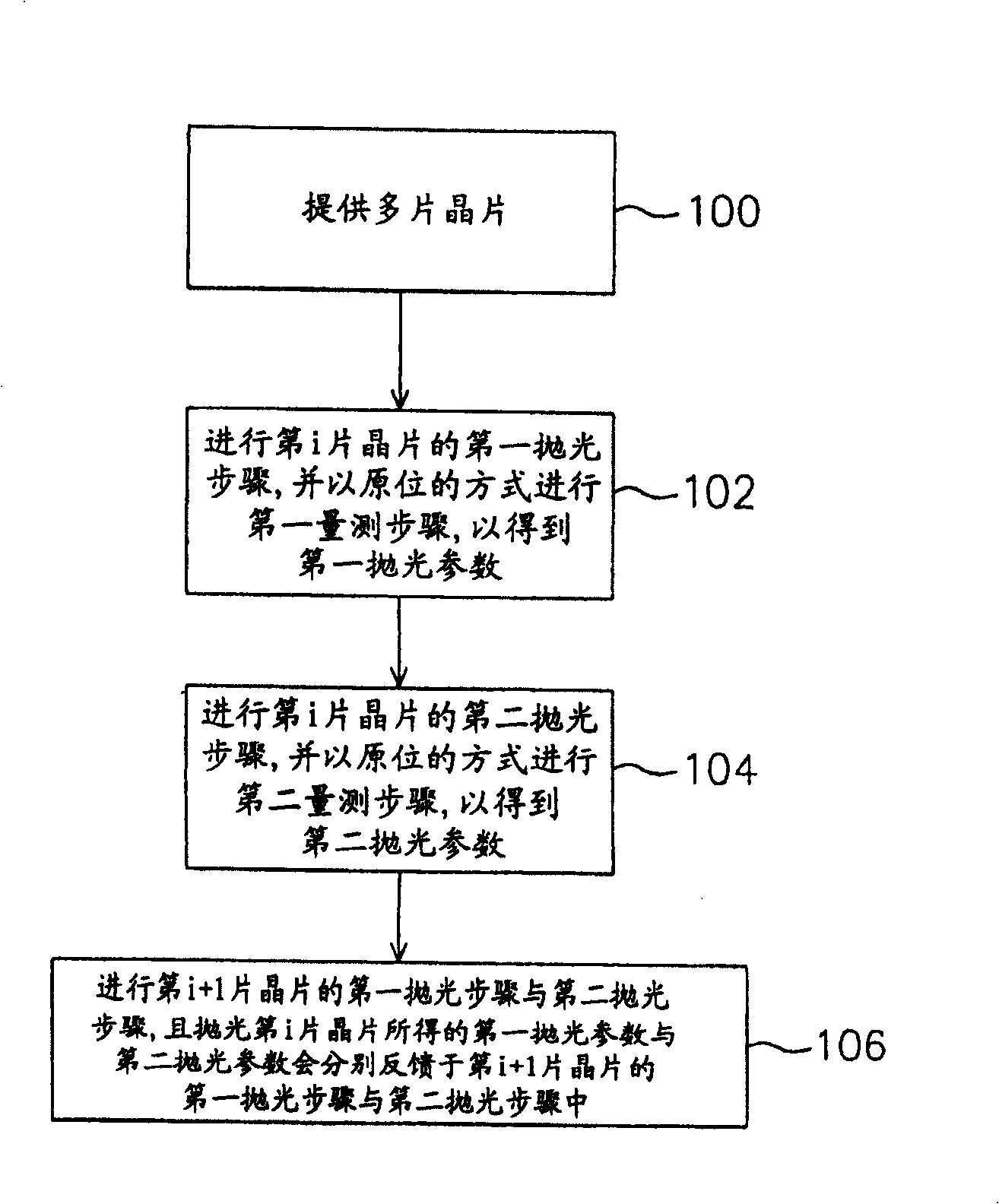

A chemical machinery and polishing machine technology, applied in polishing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of inconsistent film thickness and wafer film thickness, and achieve the effect of reducing film thickness differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

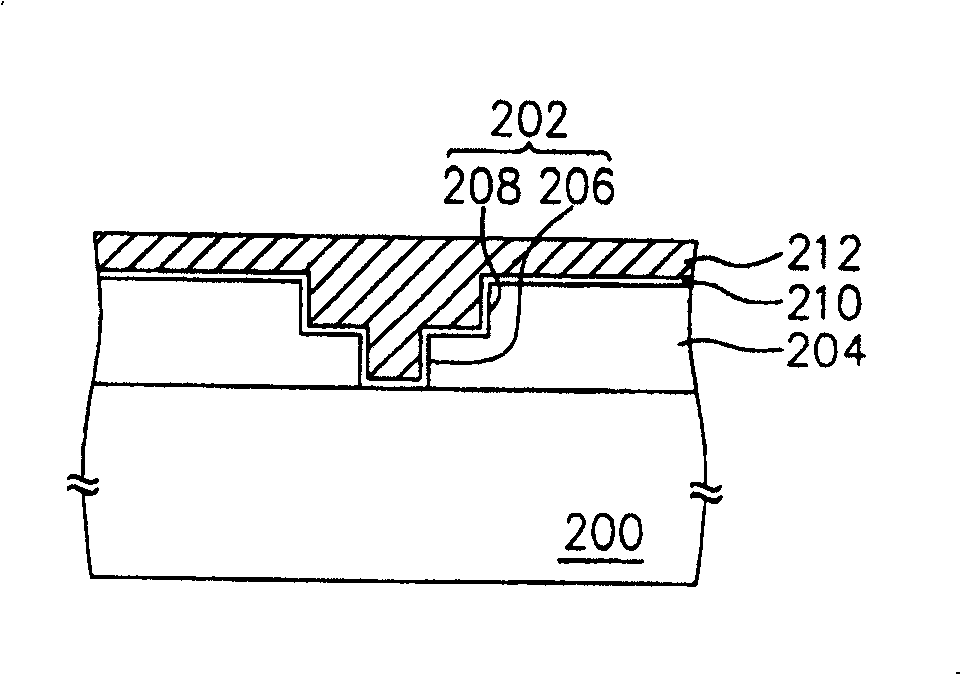

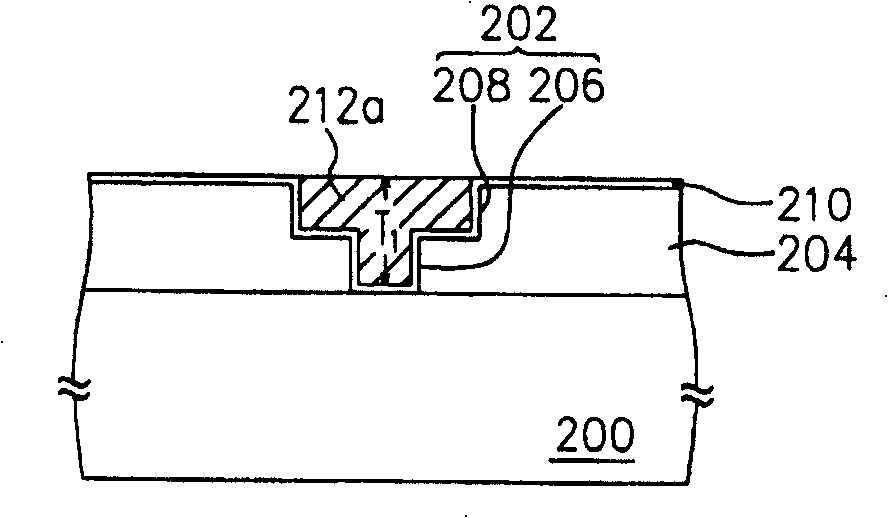

[0025] The chemical mechanical polishing equipment of the present invention is at least composed of a polishing machine, a first thickness measuring instrument and a second thickness measuring instrument, wherein the first thickness measuring instrument is connected with the polishing machine, and the second thickness measuring instrument The instrument is connected with the polishing machine.

[0026] In a preferred embodiment, the first thickness measuring instrument is, for example, a metal thickness measuring instrument, and the second thickness measuring instrument is, for example, a dielectric material thickness measuring instrument. Among them, the metal thickness measuring instrument, for example, uses the reflected waves generated by laser at different interfaces (for example, the interface between the metal layer and the dielectric layer) to measure the thickness, and the dielectric material thickness measuring instrument, for example, uses Optical principles such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com