Nozzle assembly for applying a liquid to a substrate

A nozzle device, nozzle technology, applied in the direction of the surface coating liquid device, spray device, spray device, etc., to achieve the effect of ensuring the flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

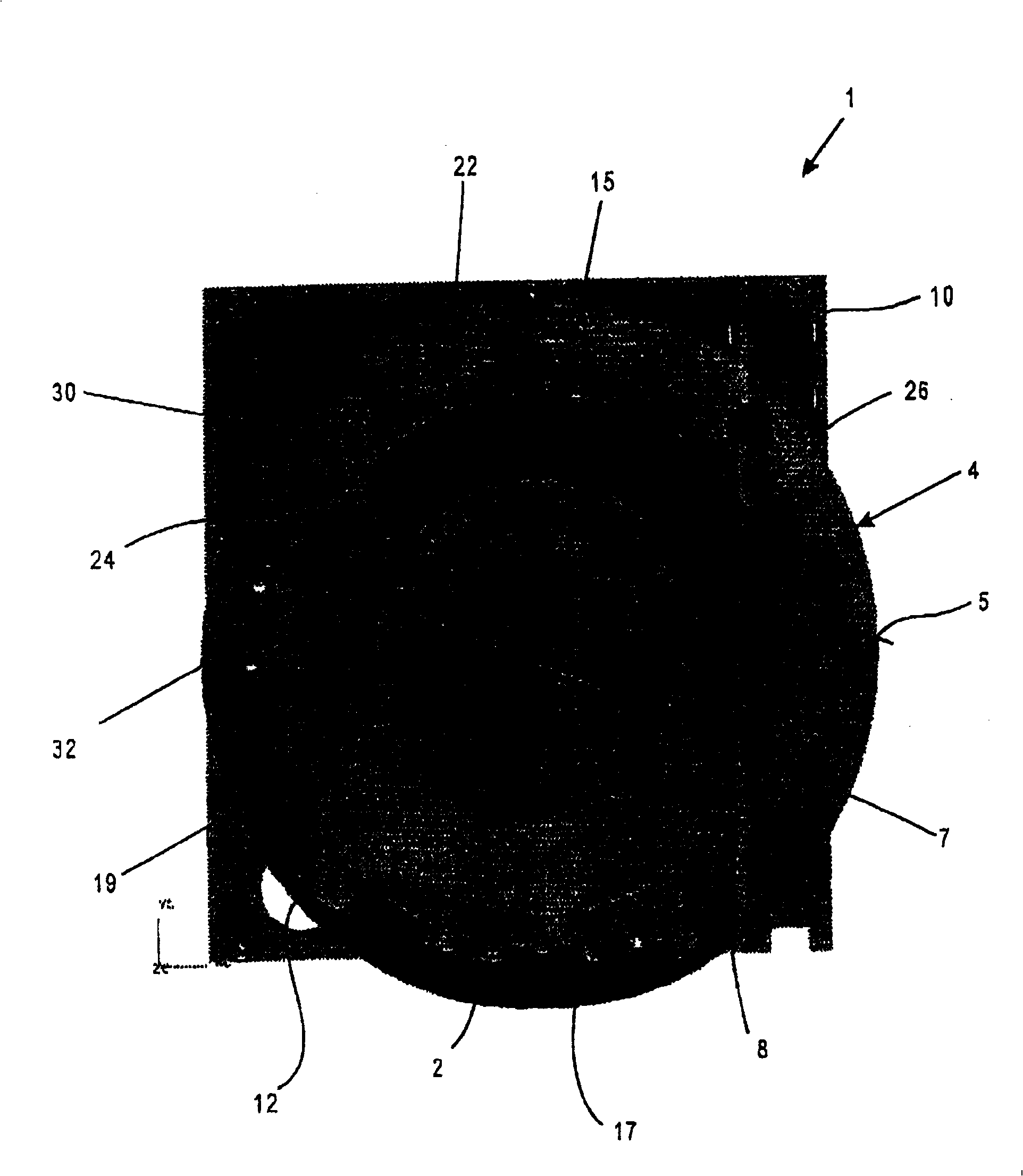

[0034] figure 1 A schematic top view of an apparatus 1 for processing photolithographic masks 2 for the manufacture of semiconductor wafers is shown. The device 1 has a treatment vessel 4 with a side wall 5 which tapers conically at least in an upper region 7 to form an upper circular inlet / outlet opening 8 . The bottom of the treatment container 4 is formed by a corresponding floor, which is fastened together with the side wall panels 5 on a fastening plate 10 . The upper inlet / outlet opening 8 can be closed by a corresponding cover, not shown in detail. In the conical part 7 of the side wall 5 a number of through-holes 12 are provided for the passage of different treatment systems, in particular feed lines for different liquids.

[0035] Inside the processing container 4 is provided with a rotatable receiving device 15, the device according to figure 1 Four support elements 17 are shown. The receiving device 15 is rotatable by means of a shaft passing through the contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com