Heat treatment method and heat treatment device

A heat treatment method and heat treatment device technology, which are applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as difficulty in temperature control of cylindrical heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

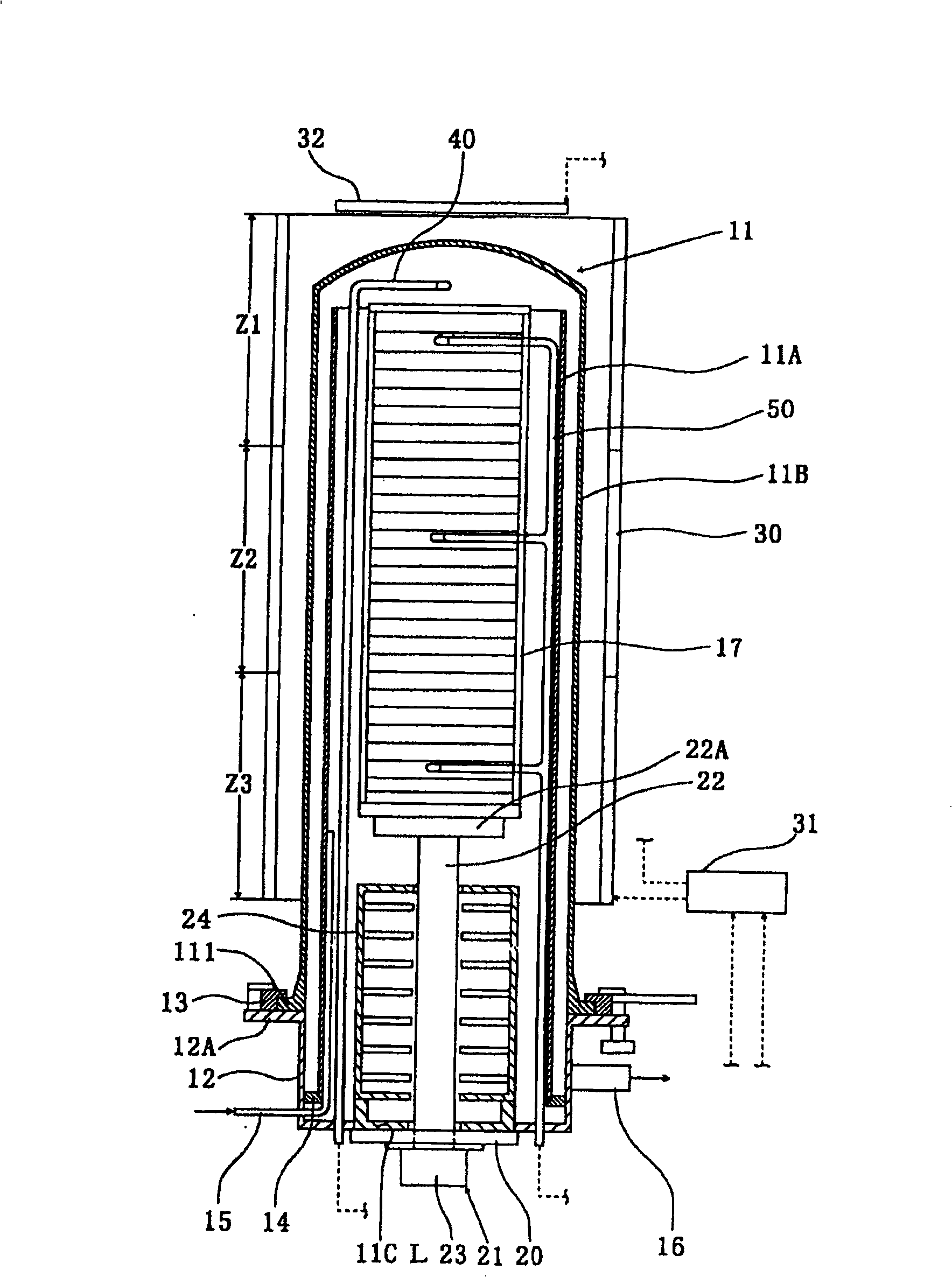

[0101] Below, explain figure 1 An embodiment of a vertical heat treatment apparatus of the structure shown.

[0102] 25 semiconductor wafers with a wafer diameter of 200mm are placed into multiple sections in the up and down direction with a pitch of 15.6mm, and the wafer tray (17) containing the simulated dummy wafer on the top and bottom is accommodated in the processing container (11 )Inside. Next, the cylindrical heater (30) and the planar heater (32) were operated with the set reference calorific value to bring all the semiconductor wafers to 800°C (target heating temperature). From the start of heating, after 2 hours, utilize the temperature detector (40) for control and the temperature detector (50) for correction to carry out temperature detection, and the temperature of the controlled object detected by the temperature detector (40) for control is 800 ° C, by The control target temperature detected by the calibration temperature detector (50) is 803°C.

[0103] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com