Automatic detecting and testing system for tripper

An automatic detection and test system technology, applied in the direction of machine/structural component testing, instruments, measuring devices, etc., can solve problems such as narrow measurement range, backward measurement methods, and low detection efficiency, so as to improve measurement accuracy and ensure consistency , to exclude the effect of random errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

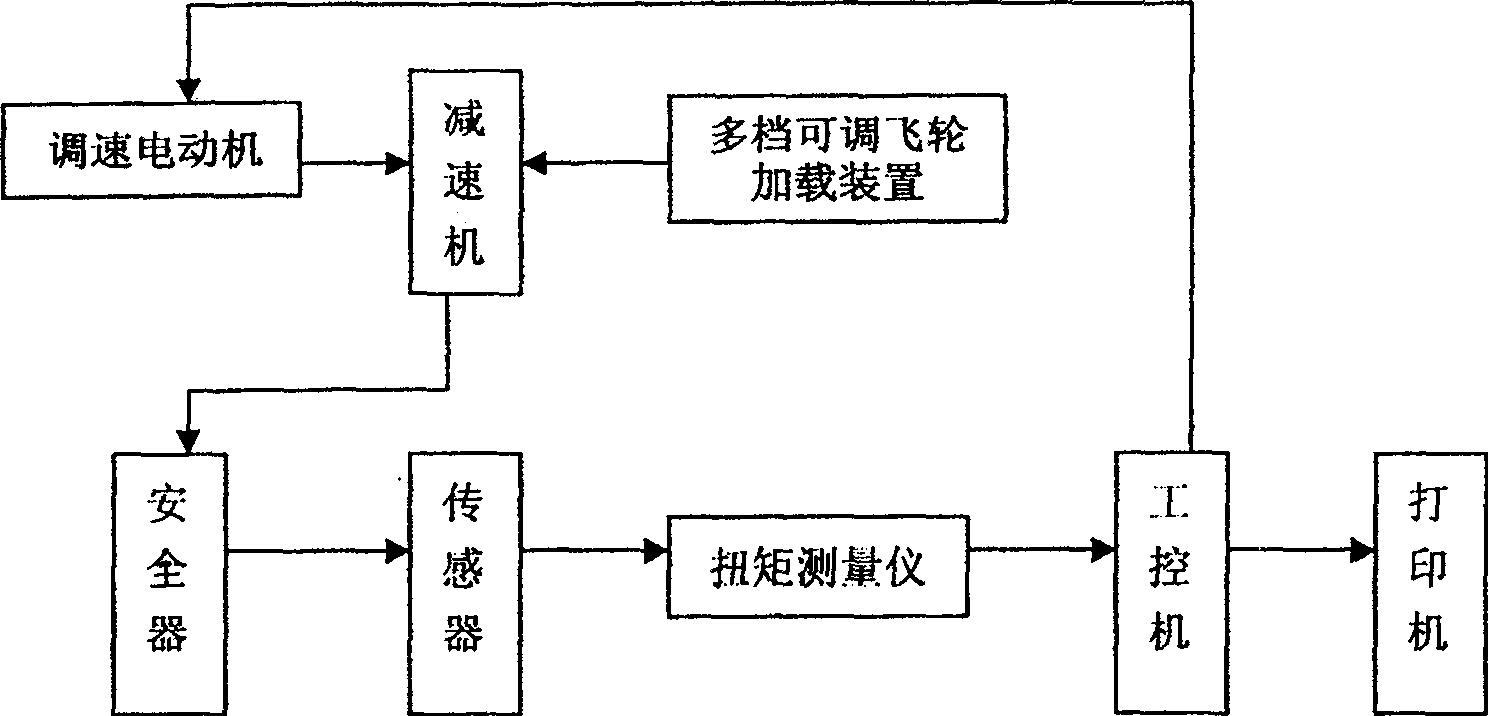

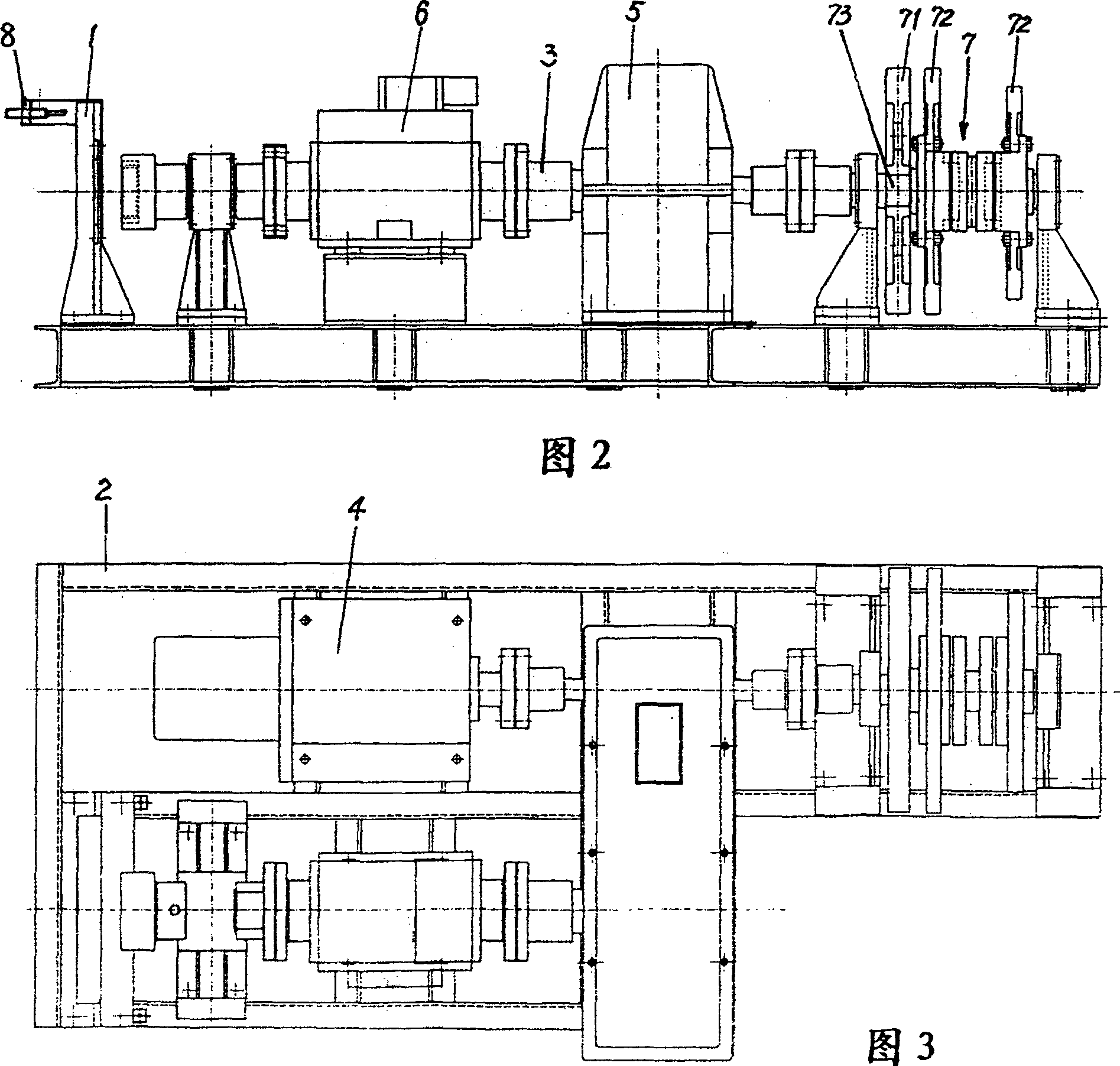

[0024] see figure 1 , Fig. 2 and Fig. 3, the present invention is a kind of safety device automatic detection test system, and it comprises anti-falling safety device detection test bench and safety device mounting bracket 1, frame 2 is equipped with on the detection test bench, arranges on frame 2 Main shaft 3, speed regulating motor 4, speed reducer 5 and flywheel device.

[0025] Sensors are also installed on the detection test bench, and the sensors include a torque speed sensor 6 and a displacement sensor 8 . The torque speed sensor 6 is connected in series between the main shaft 3 of the test bench and the safety device. The torque speed sensor 6 can be a phase difference torque speed sensor. The sensor signal is connected to the computer after the measuring instrument or the A / D card. Computer-controlled digital output controls the speed of the speed-regulating motor through D / A conversion, or uses a variable-frequency speed-regulating motor to keep the acceleration ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com