Mechanical equipment for manufacturing spring-shaped erection hoop reinforcement

A technology for mechanical equipment and erecting stirrups, which is applied in the directions of building structure, structural elements, building components, etc., can solve the problems of backward manufacturing process of erecting stirrups, low degree of mechanization, and large consumption of materials, and saves money. The effect of joint steel resource consumption, elimination of quality hidden dangers, and steel resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

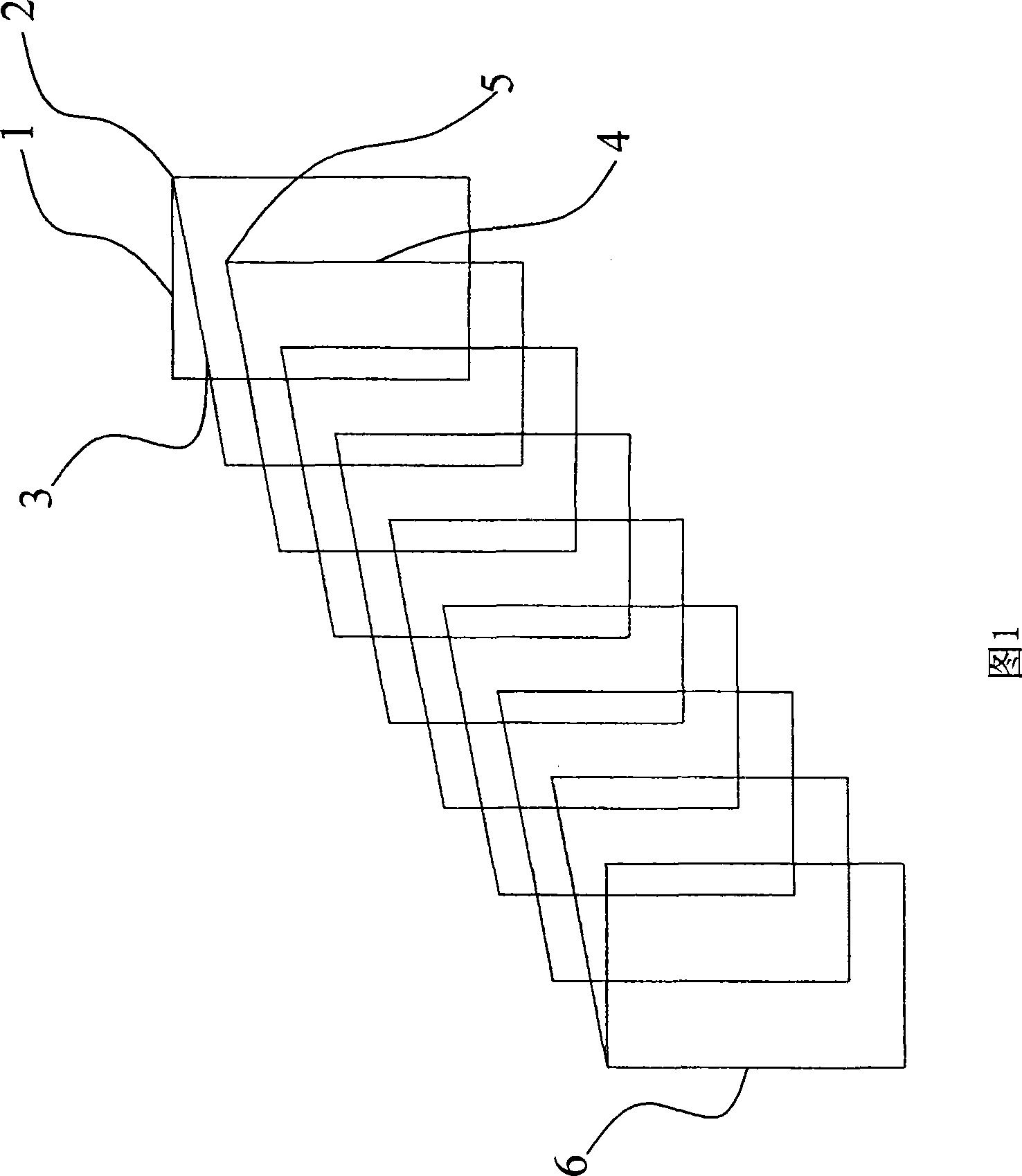

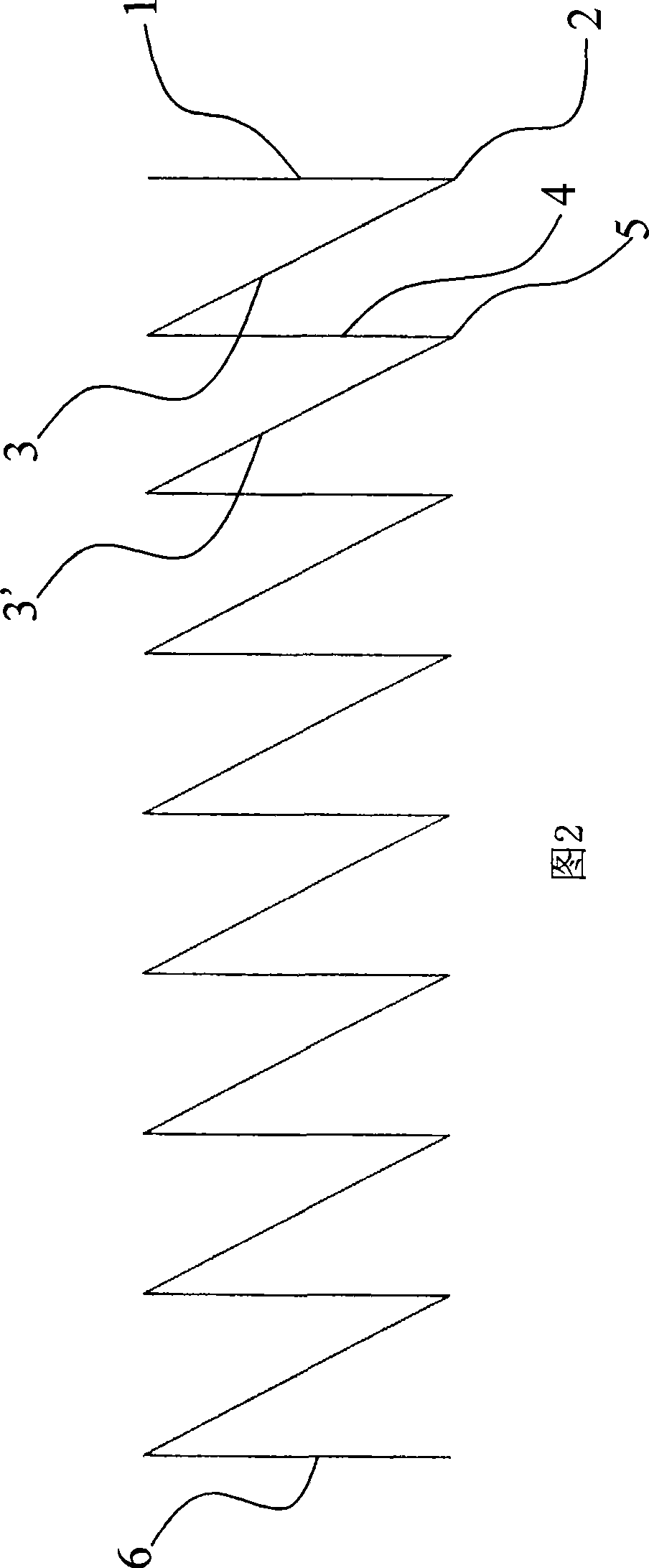

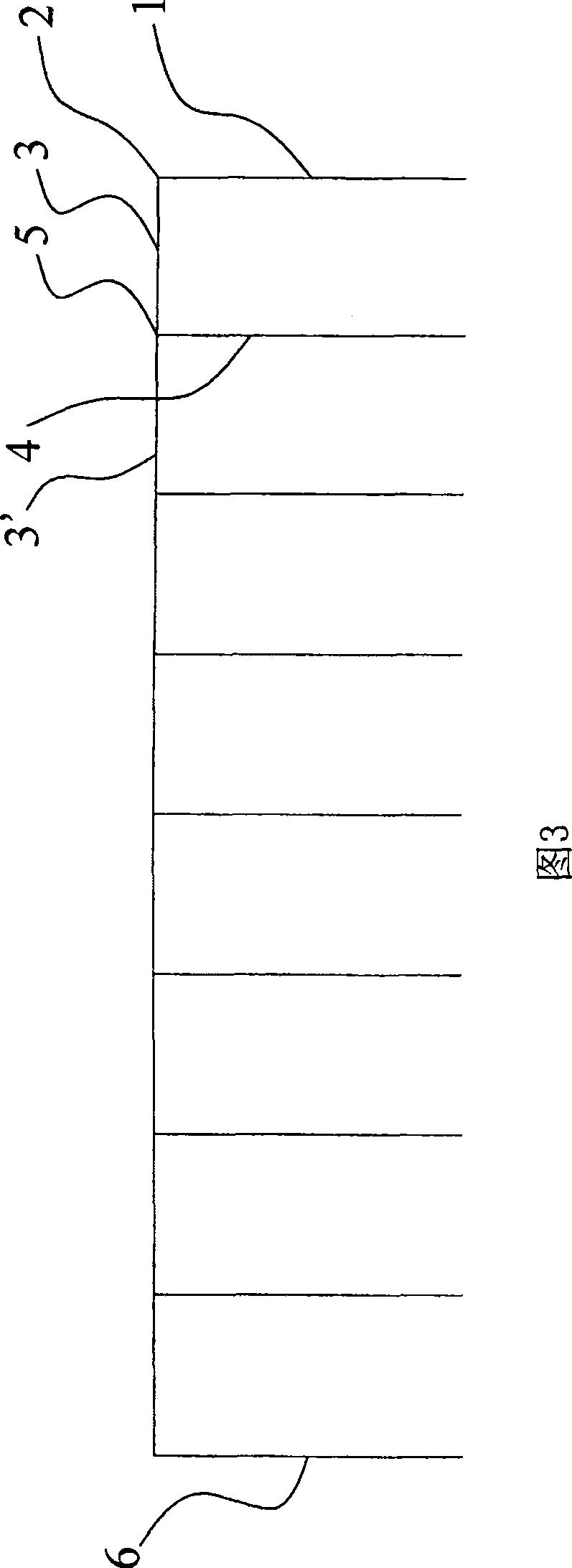

[0022] Fig. 1 is a three-dimensional view of the structure of the spring-shaped erecting stirrup of the present invention, Fig. 2 is a top view of the structure of the spring-shaped erecting stirrup of the present invention, Fig. 3 is a right view of the structure of the spring-shaped erecting stirrup of the present invention, as shown in Figures 1, 2, and 3 As shown, the spring shape erecting stirrup of the present invention is made of a steel bar, and the overall shape is a spring structure (as shown in Figure 1), and the starting end 1 of erecting the erecting stirrup is a closed rectangle, and the rectangular end 2 Bending at an angle to the rectangular surface has a hypotenuse 3, the end of the hypotenuse 3 is bent into a closed rectangle parallel to the three-sided rectangle 4, and the head end 5 of the three-sided rectangle 4 is bent again to form a parallel to the aforementioned hypotenuse The other hypotenuse 3'; repeat the aforementioned structure in turn, until the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com