Driving electrolyte and electrolytic capacitor using the same

一种电解电容器、电解液的技术,应用在液体电解电容器、电解电容器、电容器等方向,能够解决耐热性不充分、降低电导率、电解电容器性能劣化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 7

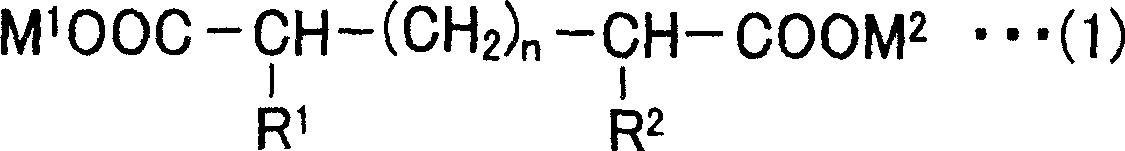

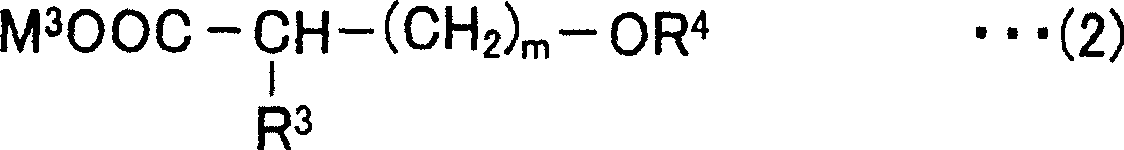

[0058] Adding to the solvent: the solute containing the compound represented by the general formula (1) and the compound represented by the general formula (2) shown in Table 1; and a nitro compound, to make each driver of Examples 1 to 7 Using the electrolytic solution, the respective driving electrolytic solutions of Comparative Examples 1 to 5 were prepared at the same time. The molar ratio 100:0 described in the following tables means that the ratio of "the number of moles of the compound represented by the general formula (1)" to "the number of moles of the compound represented by the general formula (2)" is substantially In a state of 100 to 0. It can be exemplified: after removing the compound represented by the general formula (2) from the solute containing the compound represented by the general formula (1) and the compound represented by the general formula (2), it becomes The compound shown in (2) and the remaining components are the state of the compound shown by ...

Embodiment 8 to 14

[0074] To solvent addition: containing the solute of the compound shown in Table 1 by the compound shown in general formula (1) and by the compound shown in general formula (2); One or more are selected from phosphoric acid, phosphorous acid, its salt and The compound in the alkyl phosphate ester was used to prepare the driving electrolyte solutions of Examples 8 to 14, and at the same time to prepare the driving electrolyte solutions of Comparative Examples 6 to 10.

[0075] Table 4 shows the composition of these driving electrolytes, the electrical conductivity and sparkover voltage before the heating test, and the change in electrical conductivity and sparkover voltage after a heating test at 110°C for 1000 hours in an ampoule. . In this table, the change in electrical conductivity refers to the rate of increase or decrease in the electrical conductivity after 1000 hours have elapsed when the initial value is set to 100%.

[0076] Table 4

[0077]

[0078] As shown in ...

Embodiment 15 to 21

[0090] Addition of organic solvents to ethylene glycol: the solute containing the compound shown in Table 1 by the compound shown in the general formula (1) and the compound shown in the general formula (2); nitro compound and / or at least one selected From phosphoric acid, phosphorous acid, their salts and compounds in alkyl phosphates; and polyols, to make various driving electrolytes for electrolytic capacitors.

[0091] Table 6 shows the composition of these driving electrolytes, the electrical conductivity and sparkover voltage before the heating test, and the changes in electrical conductivity and sparkover voltage after a heating test at 110°C for 1000 hours in an ampoule. . In this table, the change in electrical conductivity refers to the rate of increase or decrease in the electrical conductivity after 1000 hours have elapsed when the initial value is set to 100%.

[0092] Table 6

[0093]

[0094] As shown in Table 6, each driving electrolytic solution of Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com