Lead frame for semiconductor device and manufacturing methode thereof

A technology of lead frame and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of semiconductor device cost increase and high cost ratio, and achieve faster response speed and lower overall price, effect of reducing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

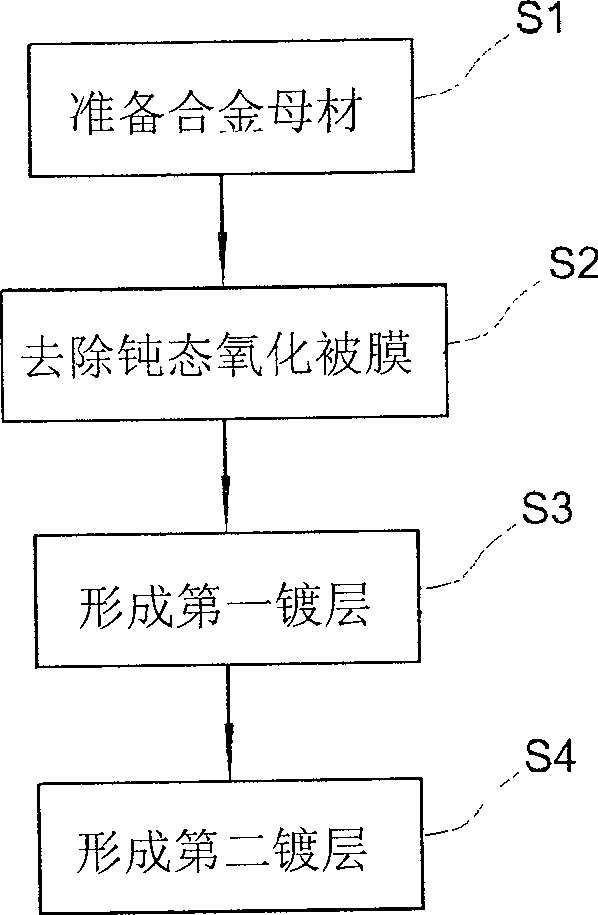

[0030] Hereinafter, the present invention will be described in detail with reference to the drawings.

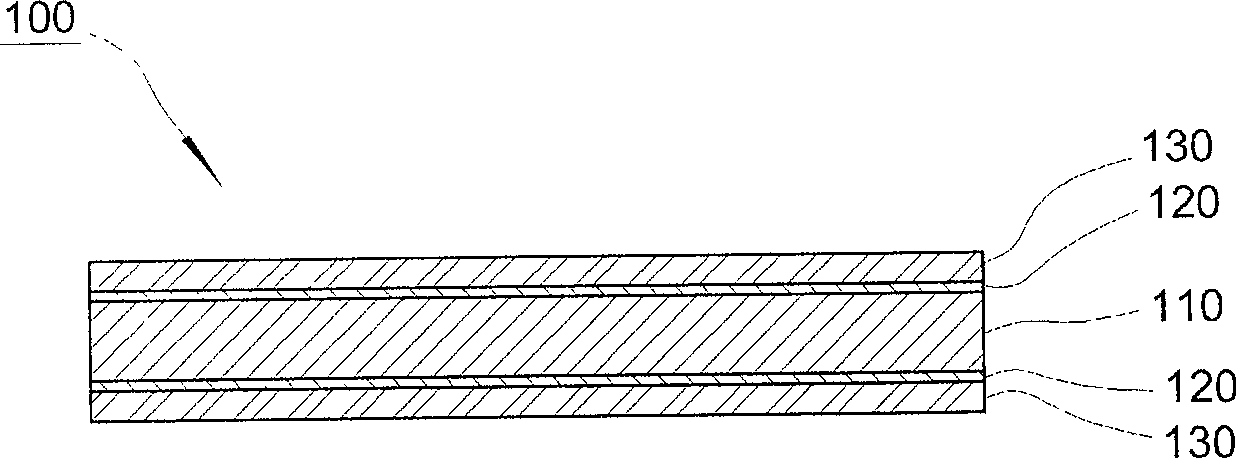

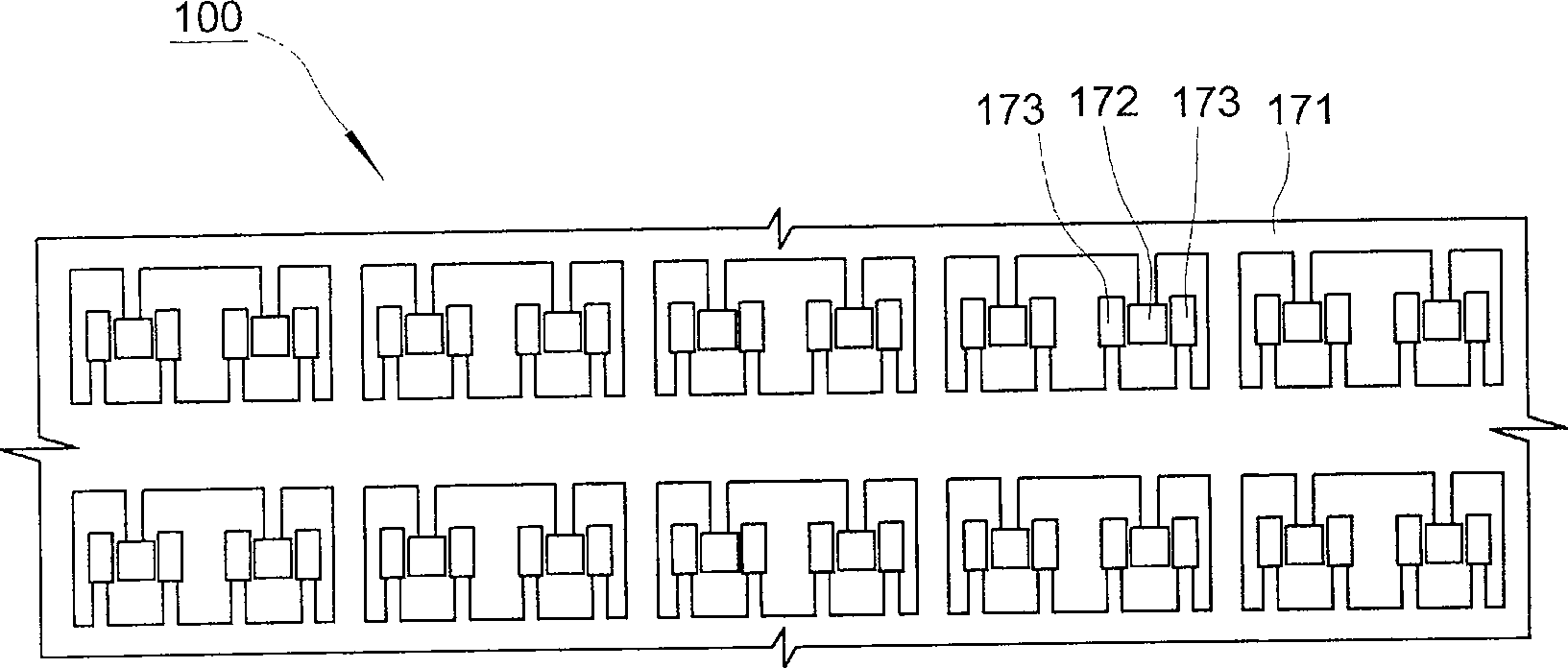

[0031] Figure 1a is a sectional view showing a lead frame for a semiconductor device of the present invention; Figure 1b It is a plan view showing an example of a lead frame after punching or etching.

[0032] Such as Figure 1a As shown, the semiconductor device lead frame 100 of the present invention includes: an alloy base material 110 of a predetermined thickness, a first plating layer 120 formed with a predetermined thickness on at least one surface of the alloy base material 110, and a first plating layer 120 formed on the aforementioned first plating layer The second plating layer 130 is formed with a predetermined thickness on the surface of 120 .

[0033] Such as Figure 1b As shown, the stamped or etched leadframe 100 may include: a frame 171 maintaining a prescribed shape, a diepad 172 connected to the aforementioned frame 171 and bonded to a semiconductor die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com