Slagging-resistance and high temperature corrosion resistance coal powder burning device used in vertical strong/weak combustion boiler

A thick-lean combustion and pulverized coal combustion technology, which is applied to the burner of burning powder fuel, the supply of combustion air/fuel, the burner, etc., can solve the problems of slagging and high-temperature corrosion, reduce high-temperature corrosion, prevent premature The effect of deflection and reducing slagging in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

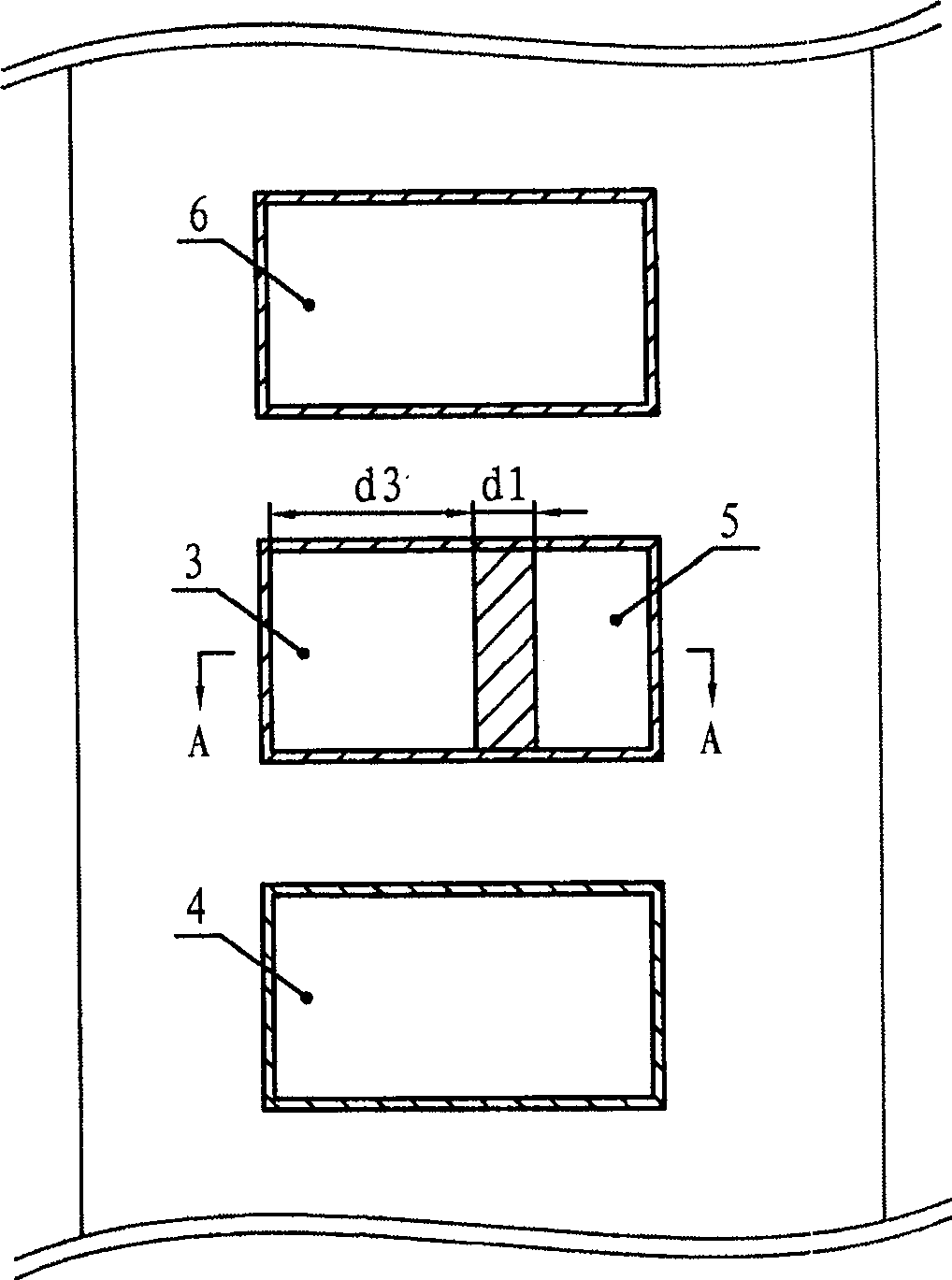

[0009] Specific implementation manner one: see figure 1 This embodiment will be described. The pulverized coal combustion device for preventing slagging and high temperature corrosion of a vertical thick and thin burning boiler of this embodiment includes a secondary air nozzle 6, a thick primary air nozzle 3, and a weak primary air nozzle 4. The secondary air nozzle 6, The dense primary air nozzles 3 and the weak primary air nozzles 4 are arranged vertically, and also include a concentrated side secondary air nozzle 5, which is fixedly installed on the back fire side of the concentrated primary air nozzle 3, and the concentrated side secondary air nozzle 5 is fixedly installed on the back fire side of the concentrated primary air nozzle 3. The distance between the air nozzle 5 and the concentrated primary air nozzle 3 is d1, and the d1 is 0 to 0.2 times the nozzle width d3 of the concentrated primary air nozzle.

[0010] In this embodiment, a thick-side secondary air nozzle 5 is...

specific Embodiment approach 2

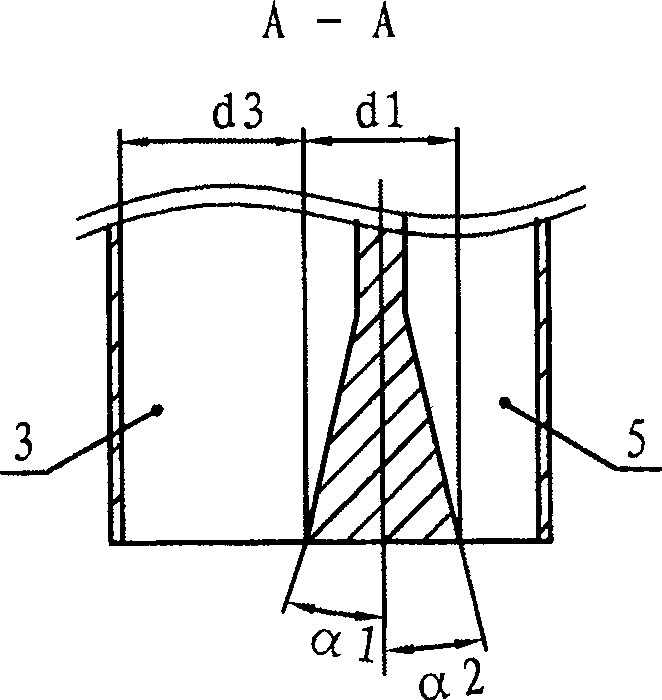

[0011] Specific implementation manner two: see figure 2 This embodiment will be described. The difference between this embodiment and the pulverized coal combustion device for preventing slagging and high temperature corrosion of a vertical dense-lean combustion boiler described in the first embodiment is that the backfire side of the dense primary air nozzle 3 is a tapered nozzle. The angle is α1, and the α1 is between 0 and 15 degrees; the fire-facing side of the rich-side secondary air nozzle 5 is a tapered nozzle, and the tapering angle is α2, and the α2 is between 0 and 15 degrees. By setting the thick primary air nozzle and the thick side secondary air nozzle as a tapered nozzle, it is equivalent to setting a bluff body between the thick primary air nozzle and the thick side secondary air nozzle, reducing the initial stage of the thick primary air jet and the side secondary air The effect of mixing is better.

specific Embodiment approach 3

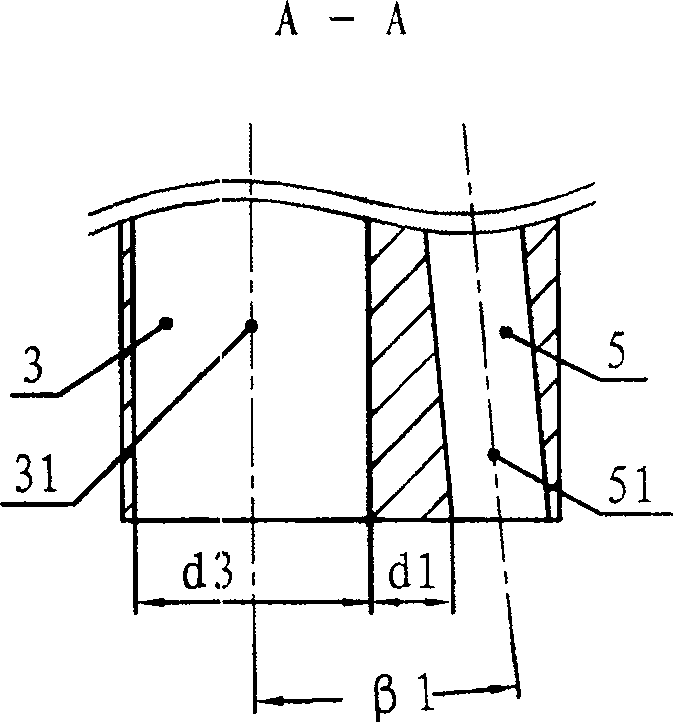

[0012] Specific implementation manner three: see image 3 with Figure 4 This embodiment will be described. The difference between this embodiment and the pulverized coal combustion device for preventing slagging and high temperature corrosion of a vertical rich-lean burning boiler described in the first embodiment is that the concentrated primary air nozzle axis 31 and the rich side secondary air nozzle axis 51 are different The included angle is β1, and the β1 is between 0 and 15 degrees.

[0013] Compared with the first embodiment, the axis 51 of the concentrated secondary air flow and the axis 31 of the concentrated primary air flow form an angle β1, which can reduce the impact of the concentrated secondary air flow on the concentrated primary air flow. The effect is to reduce the mixing of the concentrated primary air jet and the side secondary air at the beginning, and at the same time reduce the slanting of the concentrated primary air flow under the impact of the adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com