Double row burner for roaster

A combustion device and roasting furnace technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve problems affecting product quality uniformity, uneven temperature field distribution, high energy consumption of furnaces, etc., to achieve more uniform temperature, The effect of increasing temperature and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

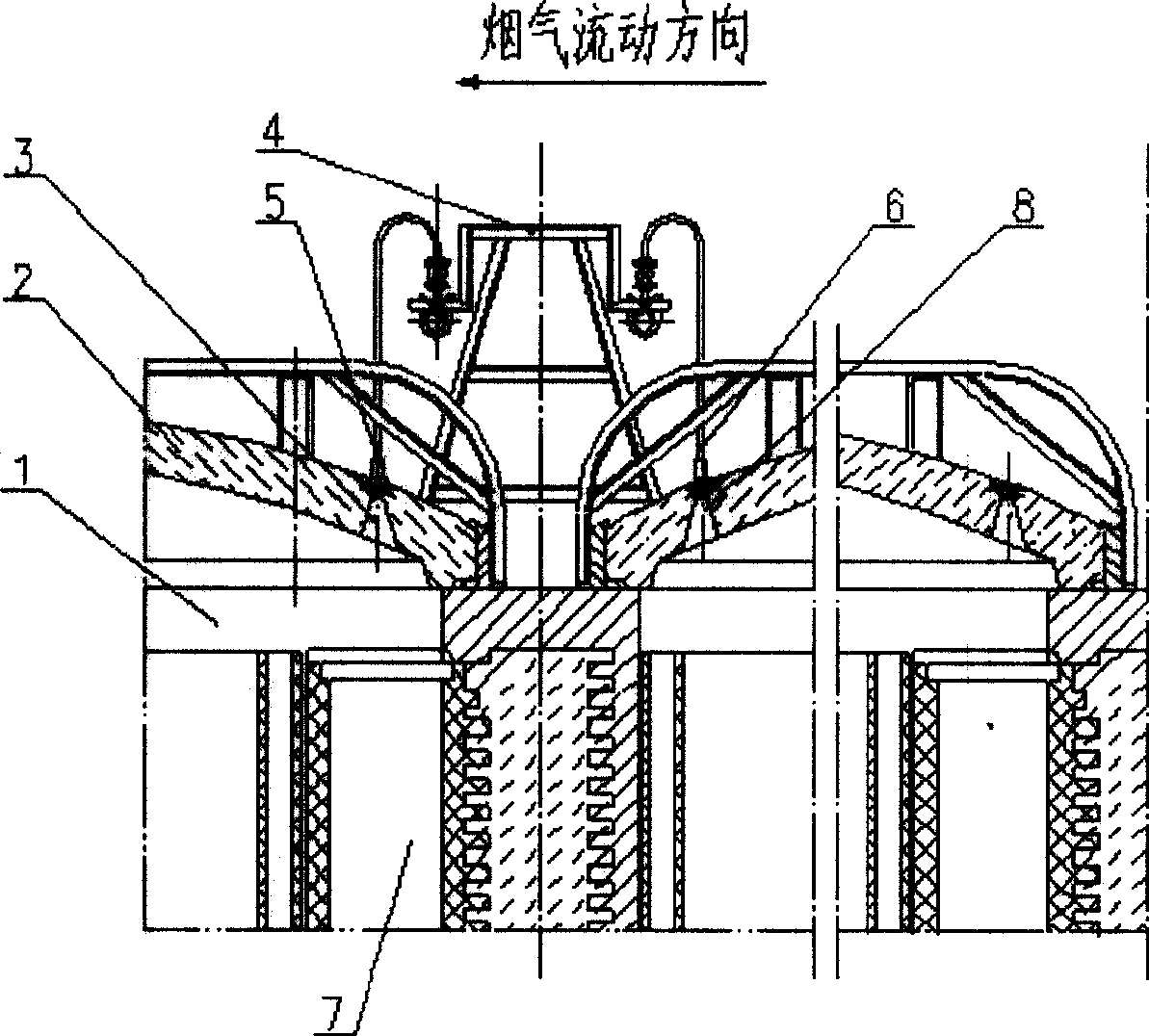

[0012] Embodiments of the present invention: on the furnace cover (2) of the furnace chamber (1), there are burner mouths (3), (8) (formerly used as observation holes), and the combustion device (4) is movable, mounted on Between the front and back furnace covers (2), the main burner (5) and the newly added auxiliary burner (6) are respectively connected through two fuel pipes. Main burner (5) is contained in the burner mouth (3) facing fire well (7), and auxiliary burner (6) is contained in the burner mouth (8) of preceding furnace cover (2) rear portion.

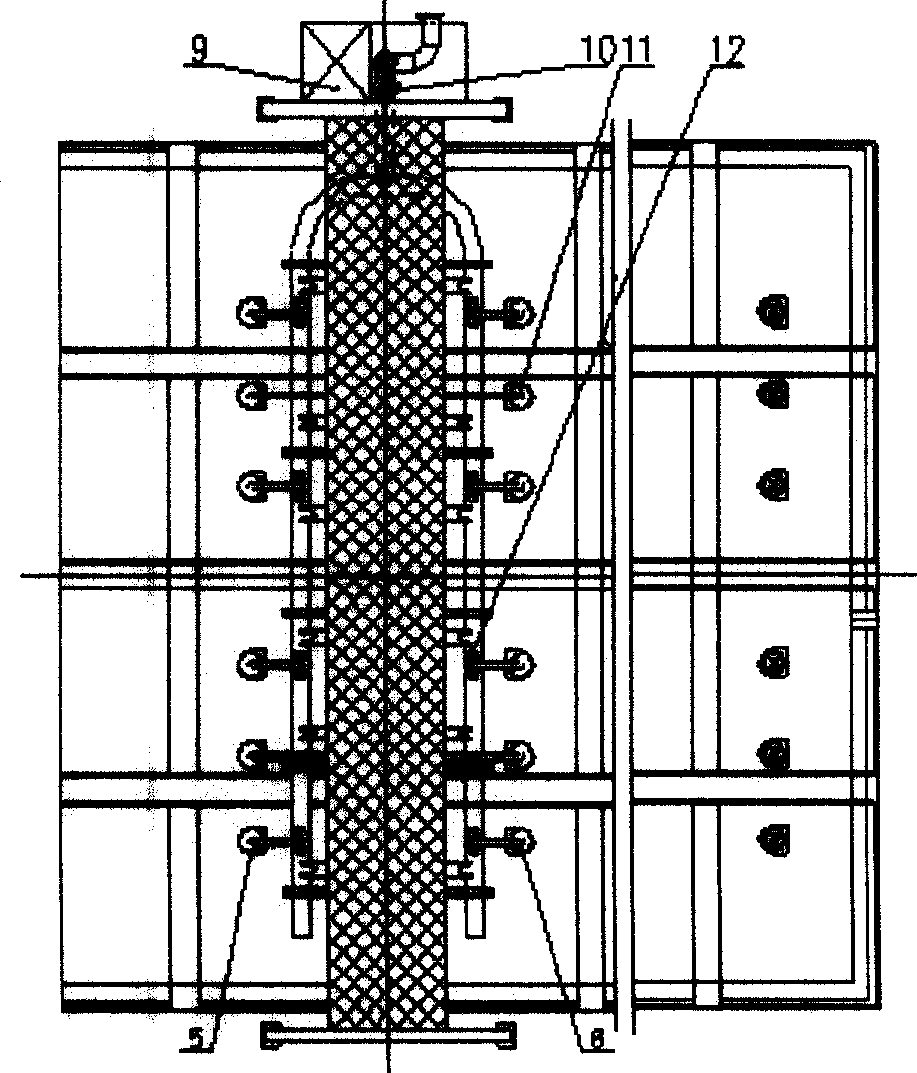

[0013] The control cabinet (9) is installed at the end of the combustion device (4), and a pressure sensor (10) and a pulse solenoid valve (12) are installed on the combustion device (4); a temperature sensor ( 11).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com