Angular velocity sensor

A technology of angular velocity sensor and amplifier, which is applied in the direction of instrument, gyro effect for speed measurement, speed/acceleration/shock measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

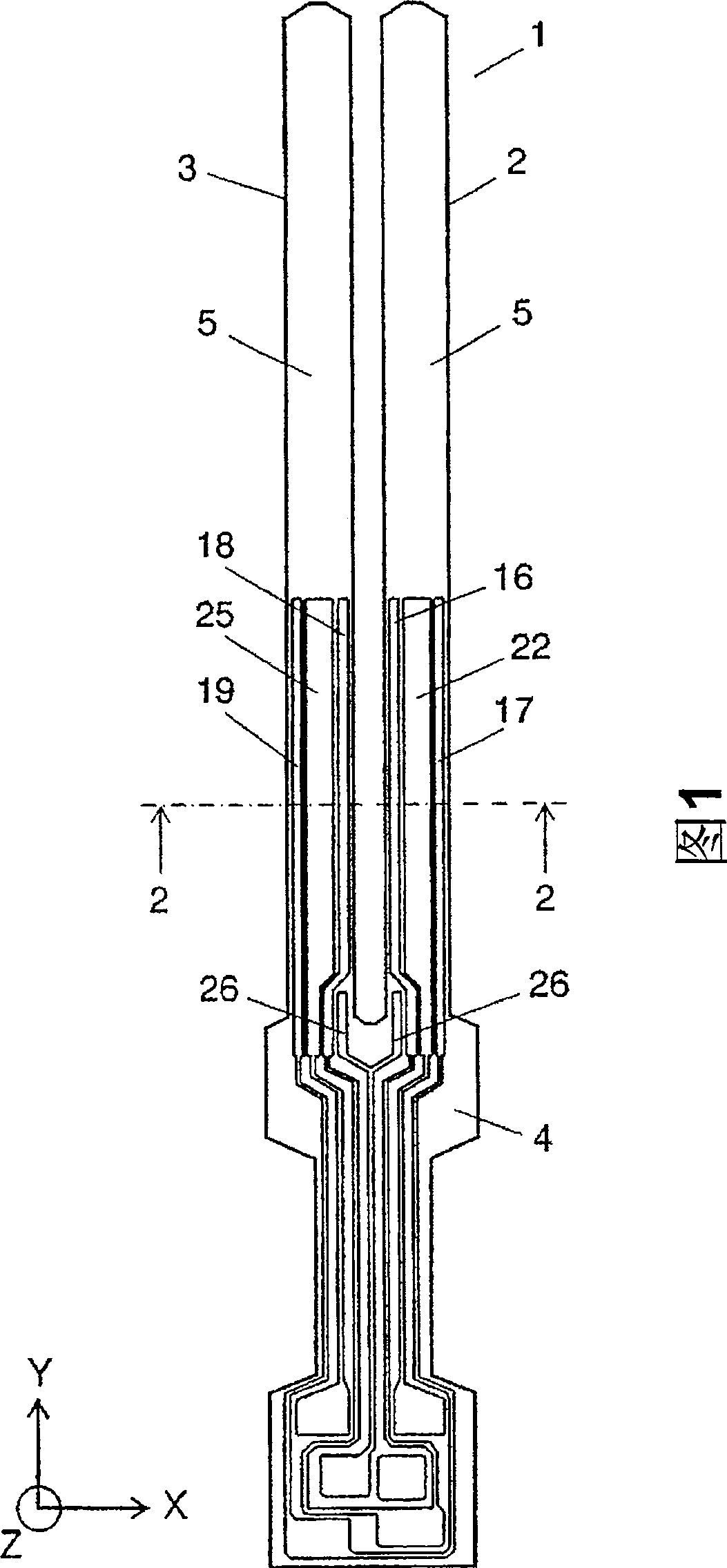

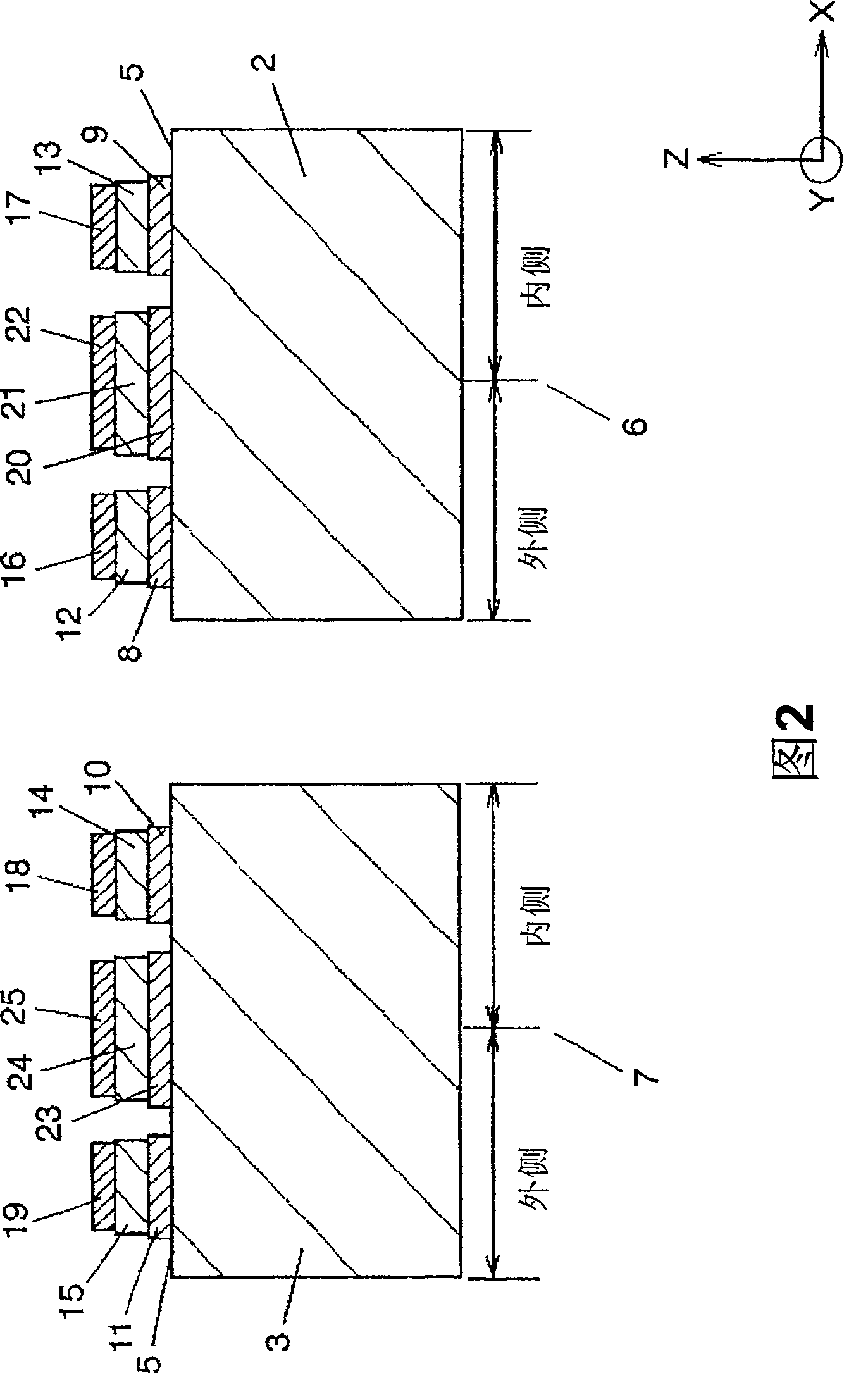

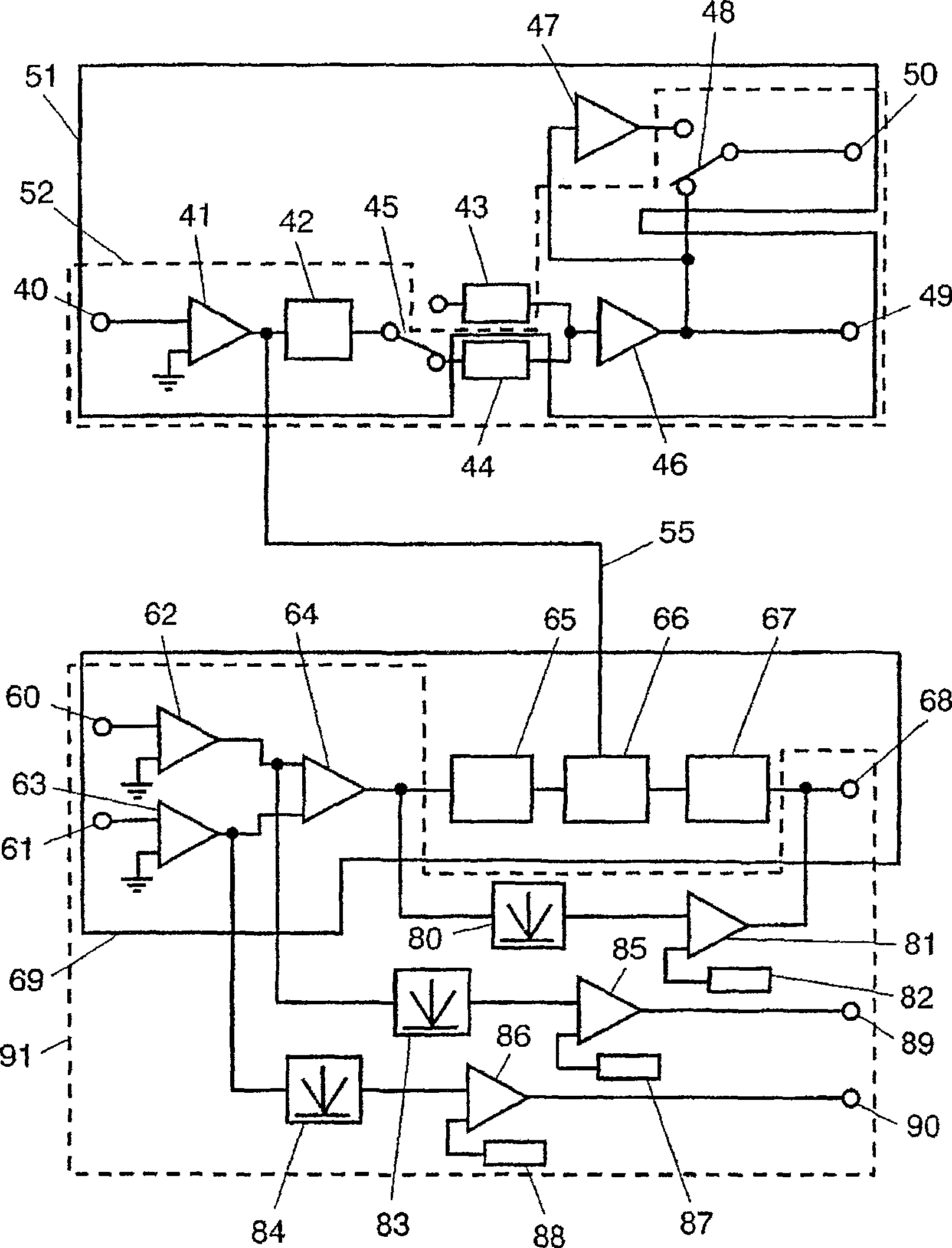

[0074] FIG. 1 is a configuration diagram of a tuning fork vibrator of an angular velocity sensor according to an embodiment of the present invention. FIG. 2 is a 2-2 sectional view of the vibrator shown in FIG. 1 . image 3 is a circuit block diagram of the angular velocity sensor in the same embodiment.

[0075] In FIGS. 1 and 2 , a tuning fork vibrator 1 made of silicon, which is a non-piezoelectric material, has arms 2 and 3 . Furthermore, the tuning fork vibrator 1 further has a base 4 . Furthermore, the arms 2 , 3 have a main surface 5 .

[0076] Front view 2, with arm 2 and arm 3 shown on its right and left, respectively.

[0077] First, note arm 2 , shown with centerline 6 . The center line 6 indicates the position of the approximately exact center of the arm 2 . A first electrode 8 serving as a common electrode is provided on the inner side of the central line 6 , that is, on the upper surface of the main surface 5 closest to the arm 3 . A first piezoelectric film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com