Simulating test table for disc type brake

A technology for simulating test benches and disc brakes, which is applied in braking safety systems, testing of machine/structural components, instruments, etc. It can solve the problems of high cost and low work efficiency, and achieve low cost, convenient debugging and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

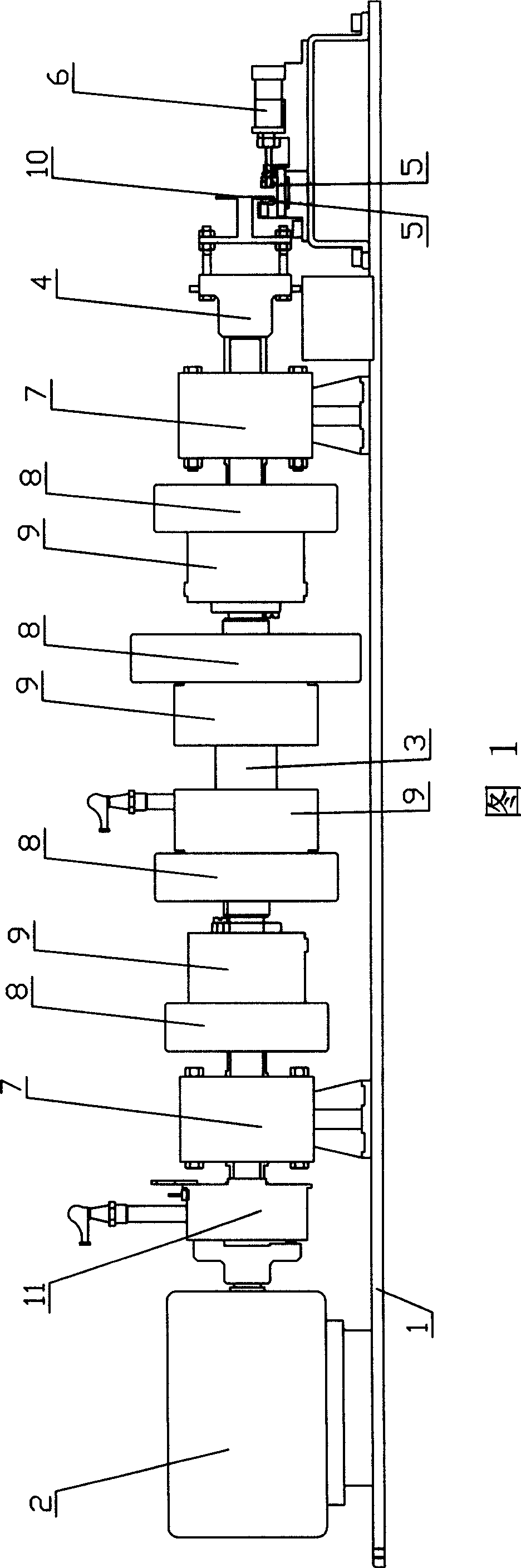

[0032] As shown in Figure 1, the embodiment of the disc brake simulation test bench of the present invention includes a stand 1, a motor 2, a main shaft 3 driven by the motor 2, a friction disc fixture 4 arranged on one end of the main shaft 3, and two friction plates 5 , Cylinder 6.

[0033] The motor 2 and the cylinder 6 are fixedly arranged on the stand 1 ; the main shaft 3 is arranged on the stand 1 through two bearing seats 7 .

[0034] Four flywheels 8 are arranged on the main shaft 3, and the flywheels 8 are arranged between two bearing seats 7. A clutch 9 is provided between each flywheel 8 and the main shaft 3 .

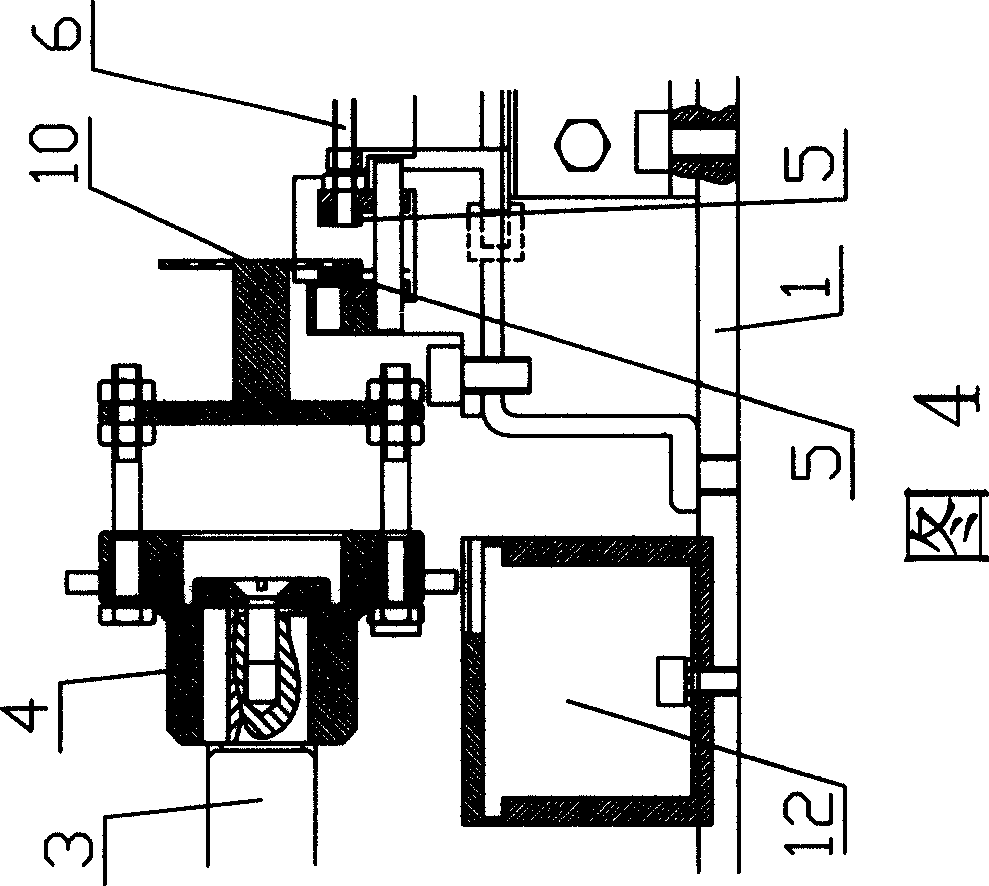

[0035] As shown in FIG. 2 , a friction disc electromagnetic clutch 11 is provided between the torque output end of the motor 2 and the main shaft 3 .

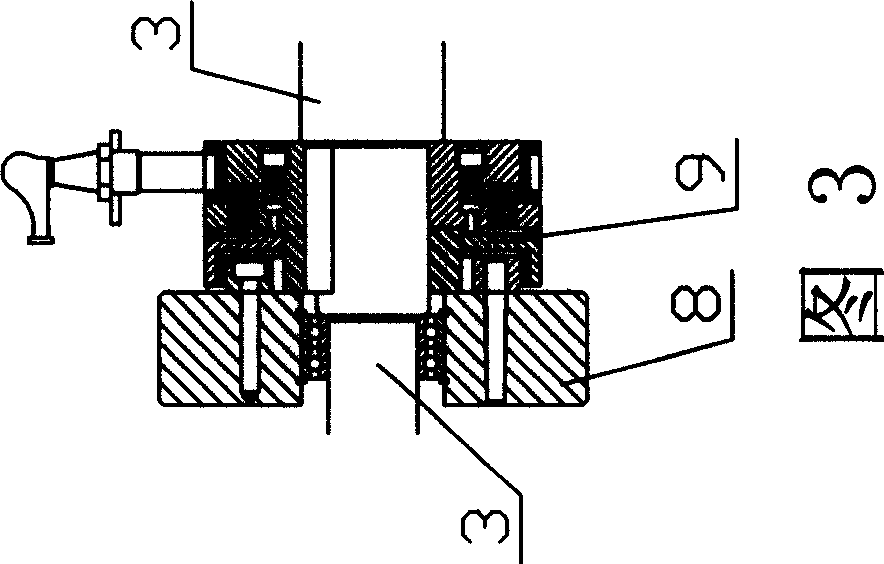

[0036] A clutch 9 is provided between each flywheel 8 and the main shaft 3. As shown in FIG. 3 , the clutch 9 between the flywheel 8 and the main shaft 3 is a toothed electromagnetic clutch.

[0037] As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com