Electromagnetically driven two-way execution micro sampler preparation method

A technology of electromagnetic drive and sampler, which is applied in the direction of sampling device, material inspection product, biological test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

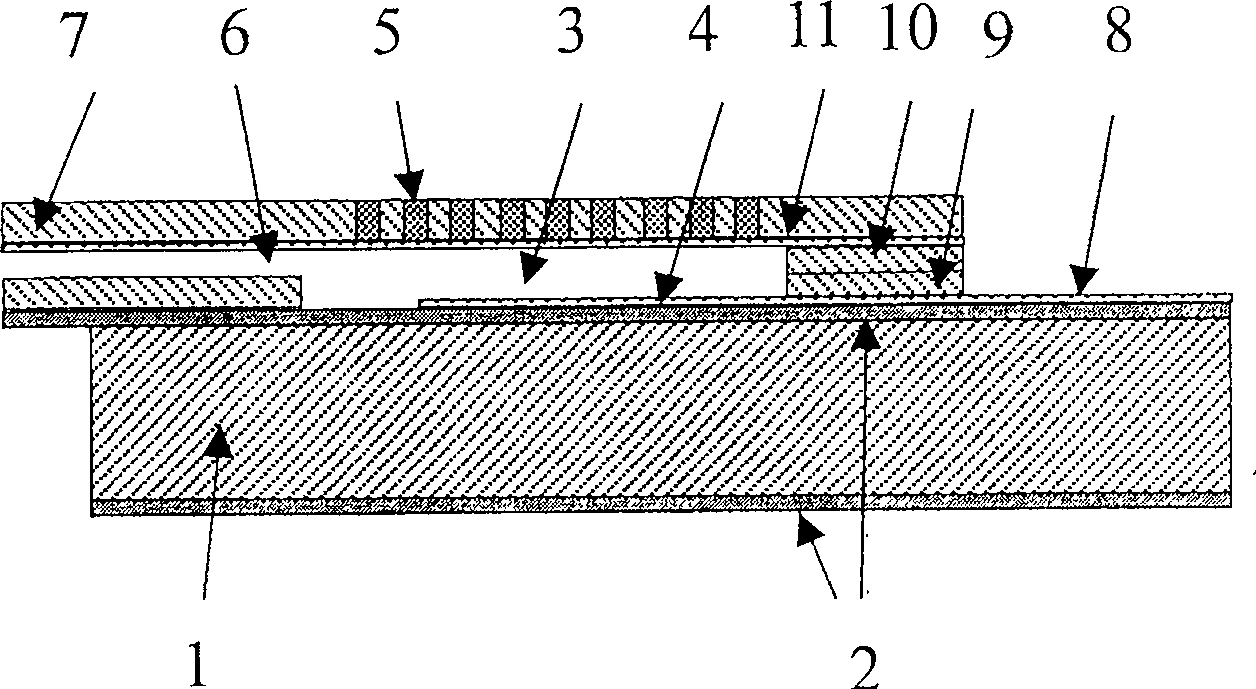

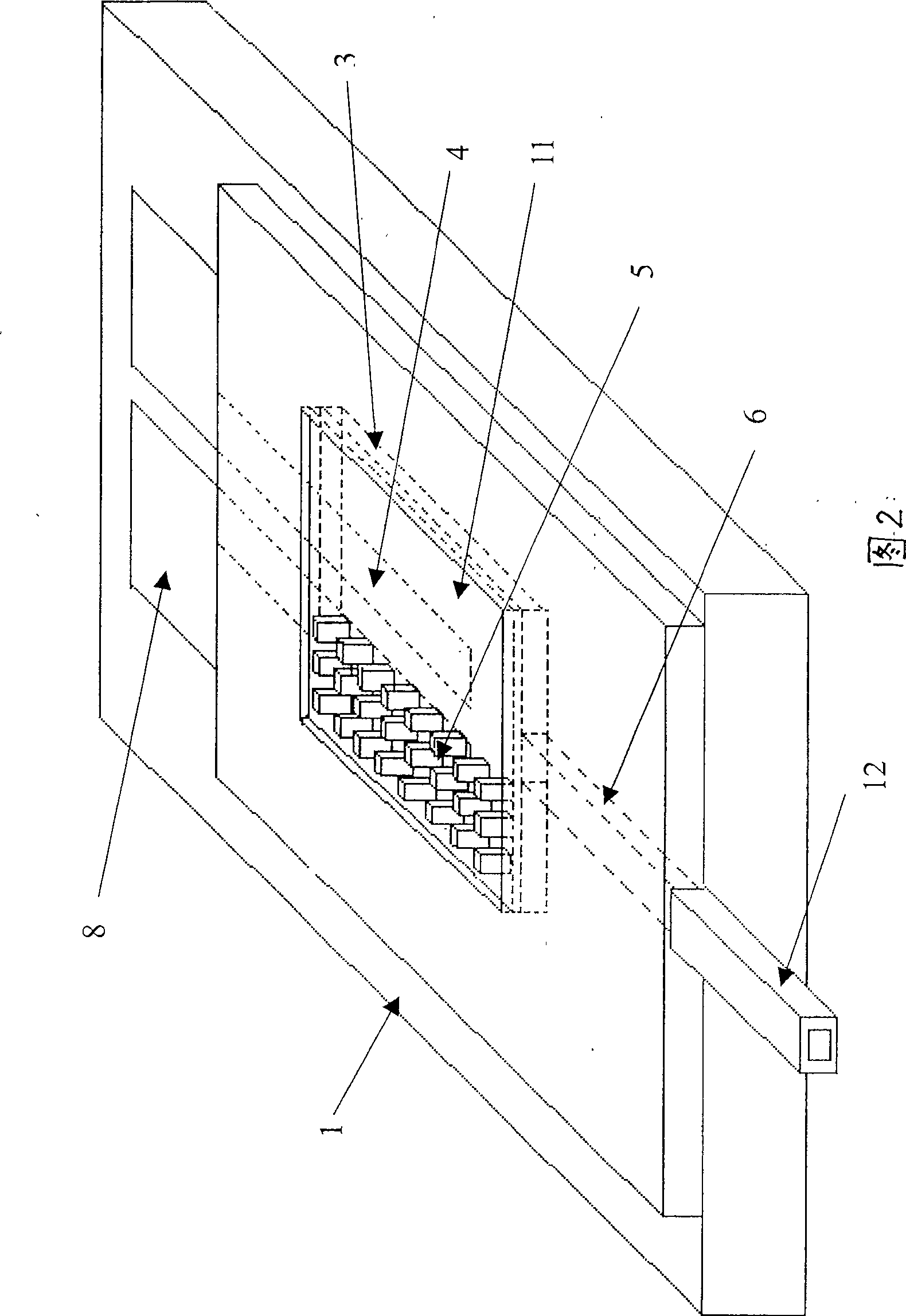

[0012] This example is on a 8×10mm 2 On the silicon substrate 1, first use LPCVD to deposit Thick silicon nitride insulating layer 2, using radio frequency sputtering method to prepare chrome-gold thin film, photoetching out the solder joint 8 pattern of gold electrode 4 external circuit connection, and then performing the first 20 μm thick SU-8 glue 9 spray glue , exposure, and make the pattern of the reaction chamber 3; then carry out the second 20 μm thick SU-8 glue 10 to throw off the glue, expose, and make the pattern that the microneedle channel 6 communicates with the reaction chamber 3; then on the SU-8 film Sputter the gold film 11, perform the third 20 μm thick SU-8 glue 7 on the gold film 11 to throw off the glue, expose it, and make a magnetic column array pattern, and perform the first development to form an electroformed magnetic array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com