Double-sided coil pipe enamel process and double-sided porcelain enamel coil-pipe

A process method and enamel technology, applied in the field of coil surface coating, to achieve the effect of firm bonding, prolonging service life and dense enamel layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

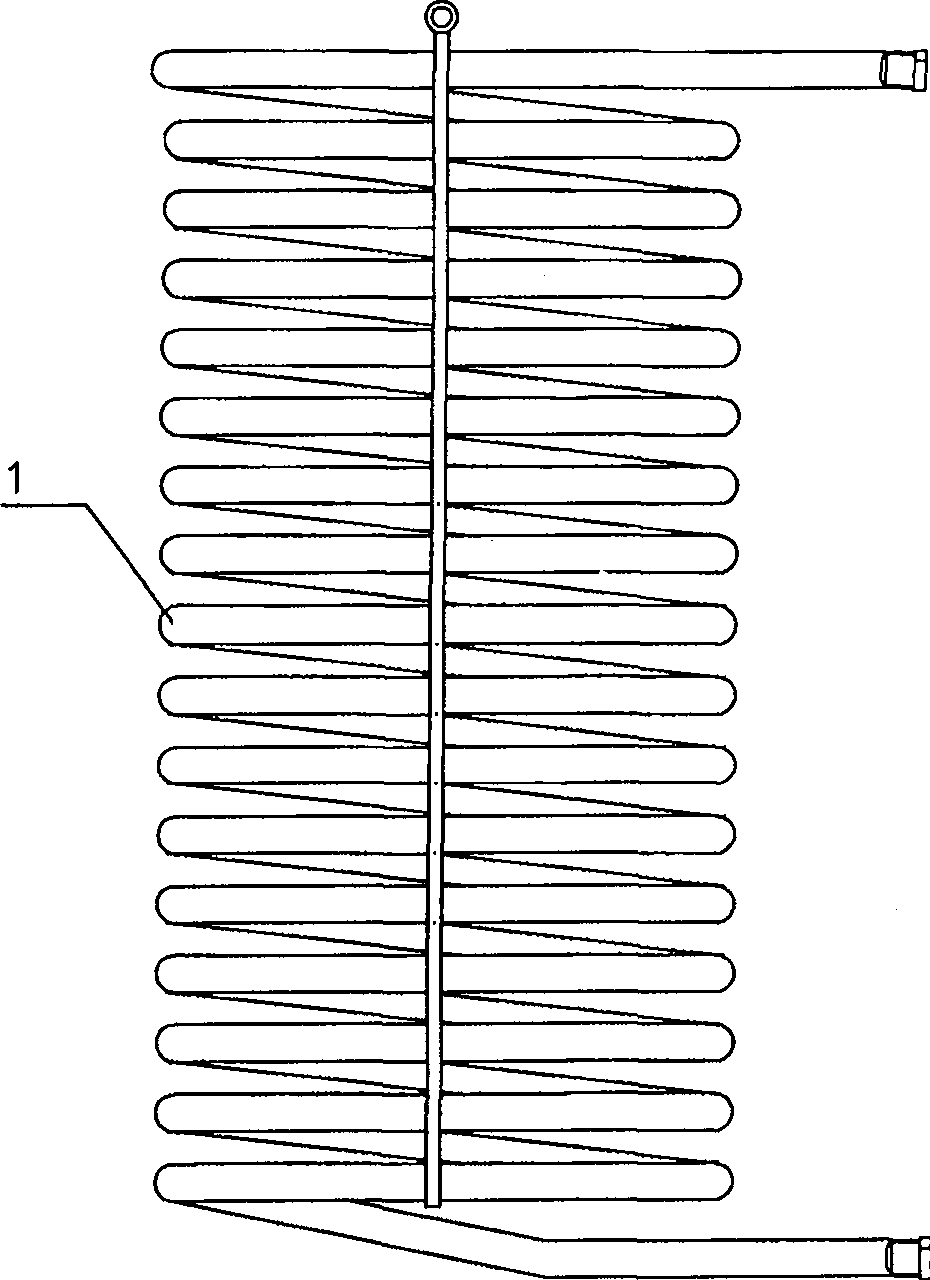

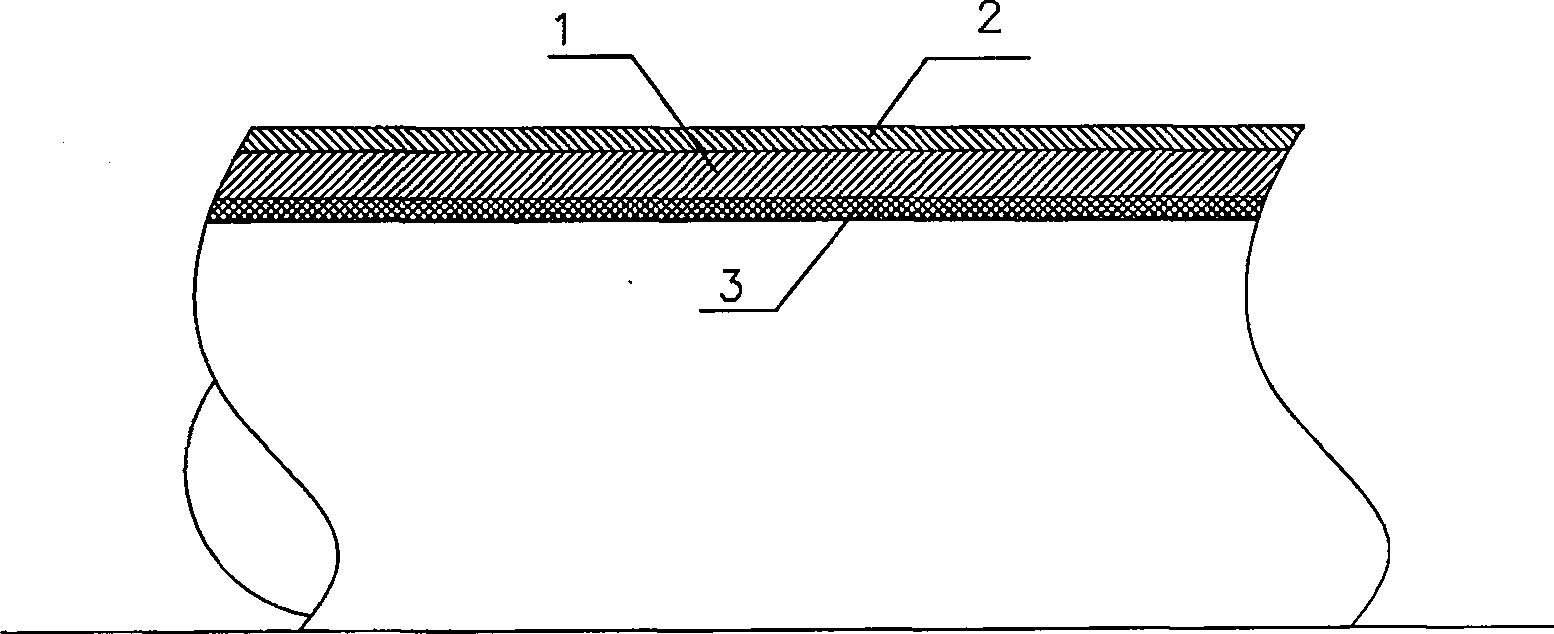

[0024] The double-sided enamel coil of this embodiment is as figure 1 As shown, the steel coil pipe body 1 is composed of a low-carbon seamless steel pipe, two reinforcing ribs welded and fixed on both sides and lifting lugs at both ends of the reinforcing ribs. The lifting lugs are used for hanging when entering the furnace for sintering, which can prevent Deformation, but also convenient for enamel coating. The low-carbon seamless steel coil has a total length of 16m. from figure 2 It can be seen from the figure that the inner and outer walls of the steel coil pipe body 1 coated with enamel have enamel layers 2 and 3 respectively. The thickness of the outer enamel layer 2 of the steel pipe is between 0.18-0.36mm; the thickness of the inner enamel layer is between 0.05-0.15mm. The above thickness can not only ensure the anti-corrosion and anti-scaling performance, but also help to ensure the quality of coating.

[0025] The entire surface coating process is:

[0026] 1)...

Embodiment 2

[0036] The basic situation of this embodiment is the same as that of Embodiment 1. The difference is that the metal substrate of the coil is thick-walled stainless steel with a total length of 8m.

[0037] Therefore, the enamel coating and sintering of the inner tube are only carried out once, and the sintering temperature is controlled at 900°C-1100°C. Experiments show that the final surface coating effect is basically the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com