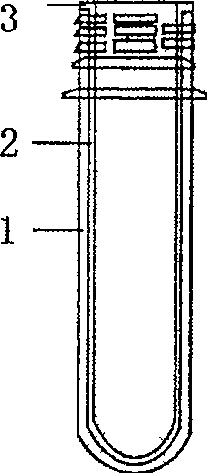

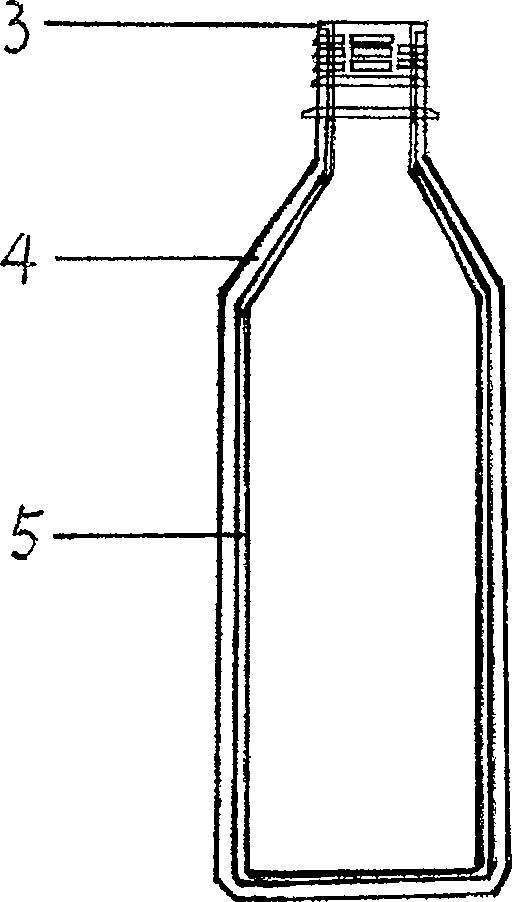

High-barrier double-wall plastic bottle excellent in allround-performance and method for manufacturing same

A plastic bottle and barrier technology, applied in the field of double-layer plastic bottles and their manufacturing, can solve the problems of difficult recycling, low melting point, high equipment and technical requirements, and achieve convenient filling line detection, excellent comprehensive performance, and bottle blowing. Process stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0049] This embodiment is realized by the following steps: (1) Take 80% PET / 20% PEN copolyester particles; (2) Take PEN particles again; (3) Choose a two-material / two-color injection molding machine with two hoppers to put two Particles, and preform molds with suitable gates and runners, adopt appropriate technology to produce double-layer preforms in two injections (or simultaneous injections); (4) Preheat the preform to 130°C and place it in a bidirectional stretch Extend the blow molding machine and blow mold, adopt appropriate technology to blow molding.

[0050] [Note] The English abbreviation of the resin involved in the article is compared with the Chinese name:

[0051] PET--Polyethylene terephthalate

[0052] PETG--Ethylene glycol modified PET

[0053] PE--Polyethylene

[0054] PP--polypropylene

[0055] PC--Polycarbonate

[0056] PVDC--Polyvinylidene Chloride

[0057] EVOH--Polyethylene-vinyl alcohol

[0058] MXD6--Polyoxalm-dimethyldiamine

[0059] PEN--polyethylene nap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com