Clamping arrangement of guide block rough milling gap

A clamping device and rough milling technology, applied in the direction of positioning device, clamping, milling machine equipment, etc., can solve the problems of unreliable fastening of workpieces, restriction of production efficiency, scrapping of workpieces, etc., and achieve convenient and secure clamping of workpieces, and firm fixation Reliable, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

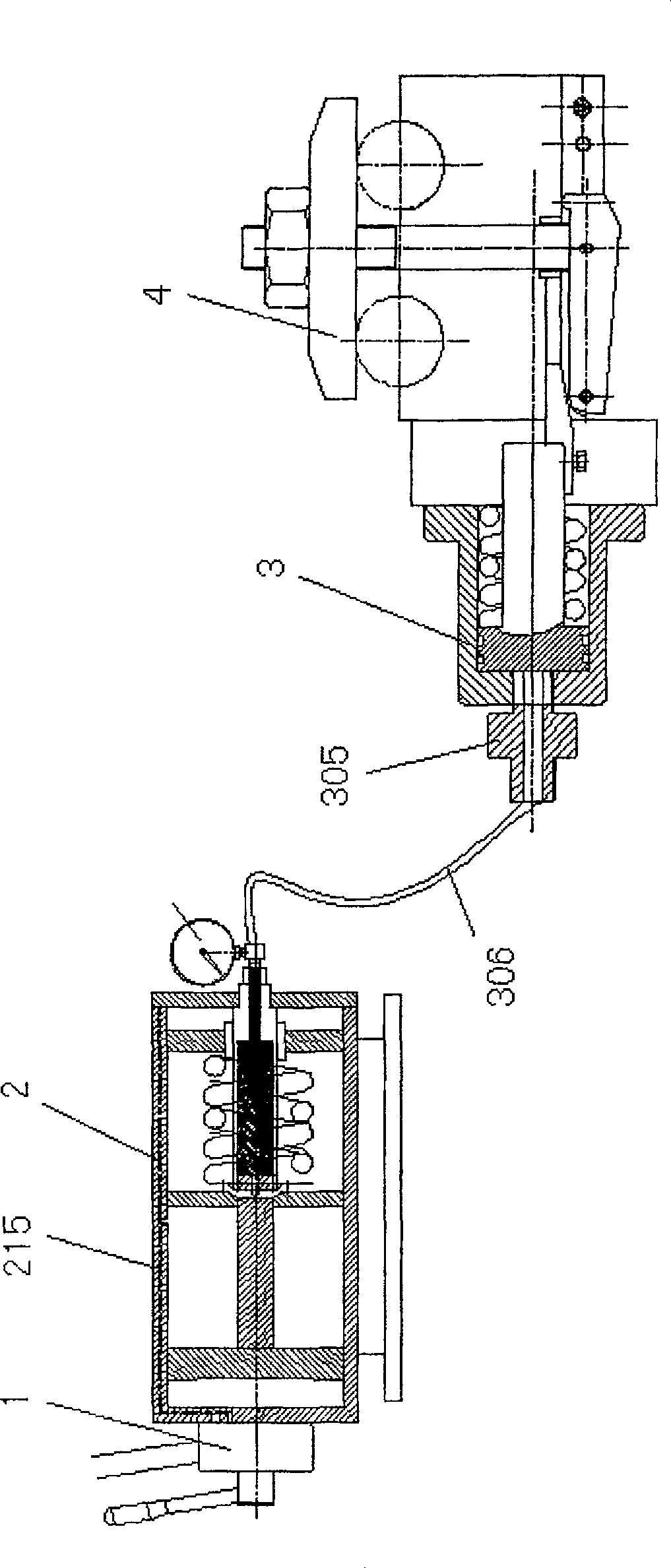

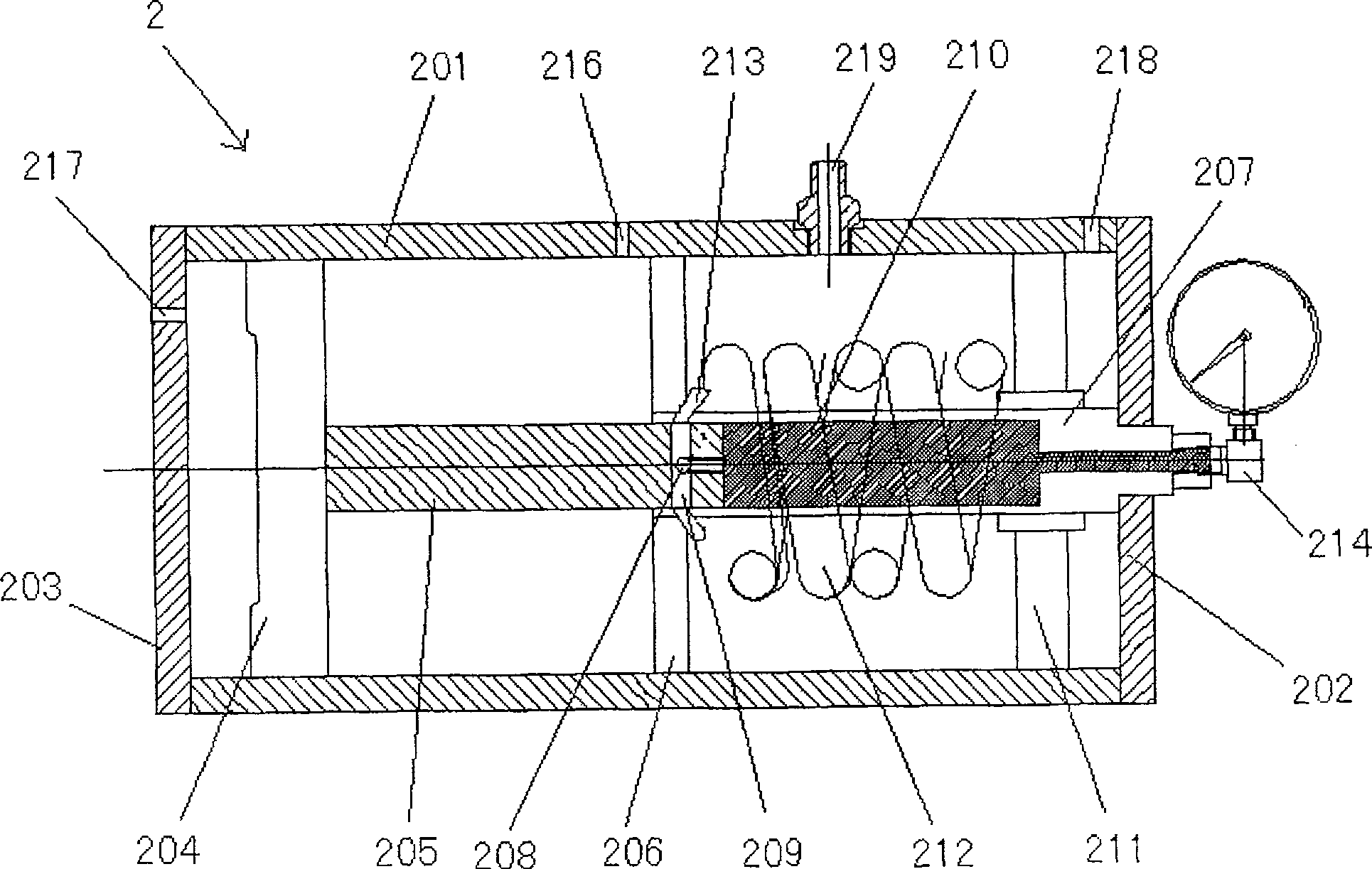

[0018] like figure 1 As shown, the present invention includes a damper control device 1, a booster oil cylinder 2 is connected at one end of the damper control device 1, and a working oil cylinder 3 is connected through an oil pipe at the other end of the booster oil cylinder 2, and the output end of the working oil cylinder 3 Connect the moving end of a workpiece clamping mechanism 4.

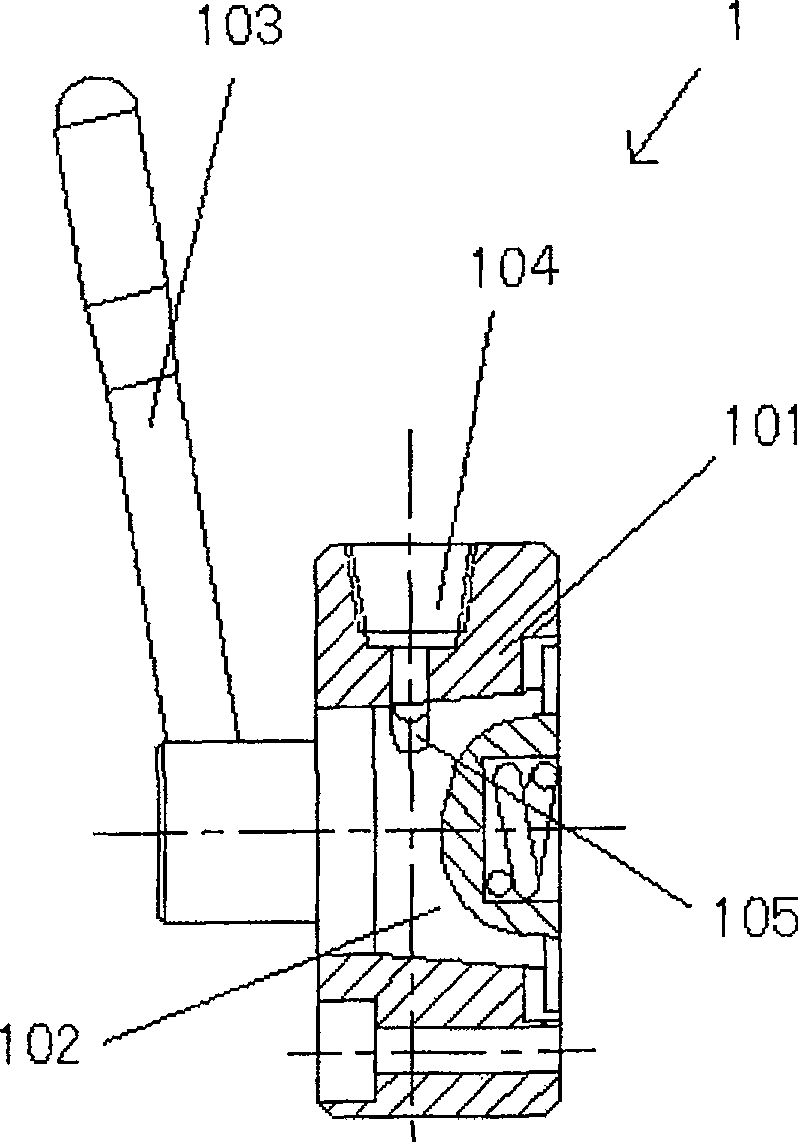

[0019] like figure 1 , figure 2 As shown, the damper control device 1 of the present invention includes: a damper body 101 , a damper core 102 is arranged inside the damper body 101 , and a handle switch 103 is set at one end of the damper core 102 . The end surface of the air valve body 101 is marked with three gears of 0, 1, and 2, and a high-pressure air port 104 is arranged on the circumference of the air valve body 101, and the high-pressure air port 104 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com