Small-sized refrigerating compressor oil level pipe and liquid level device

A compressor unit, refrigeration compression technology, applied in the direction of refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of equipment idling without refrigeration, pollution, insufficient liquid volume, etc., and achieve safe operation, convenient use, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

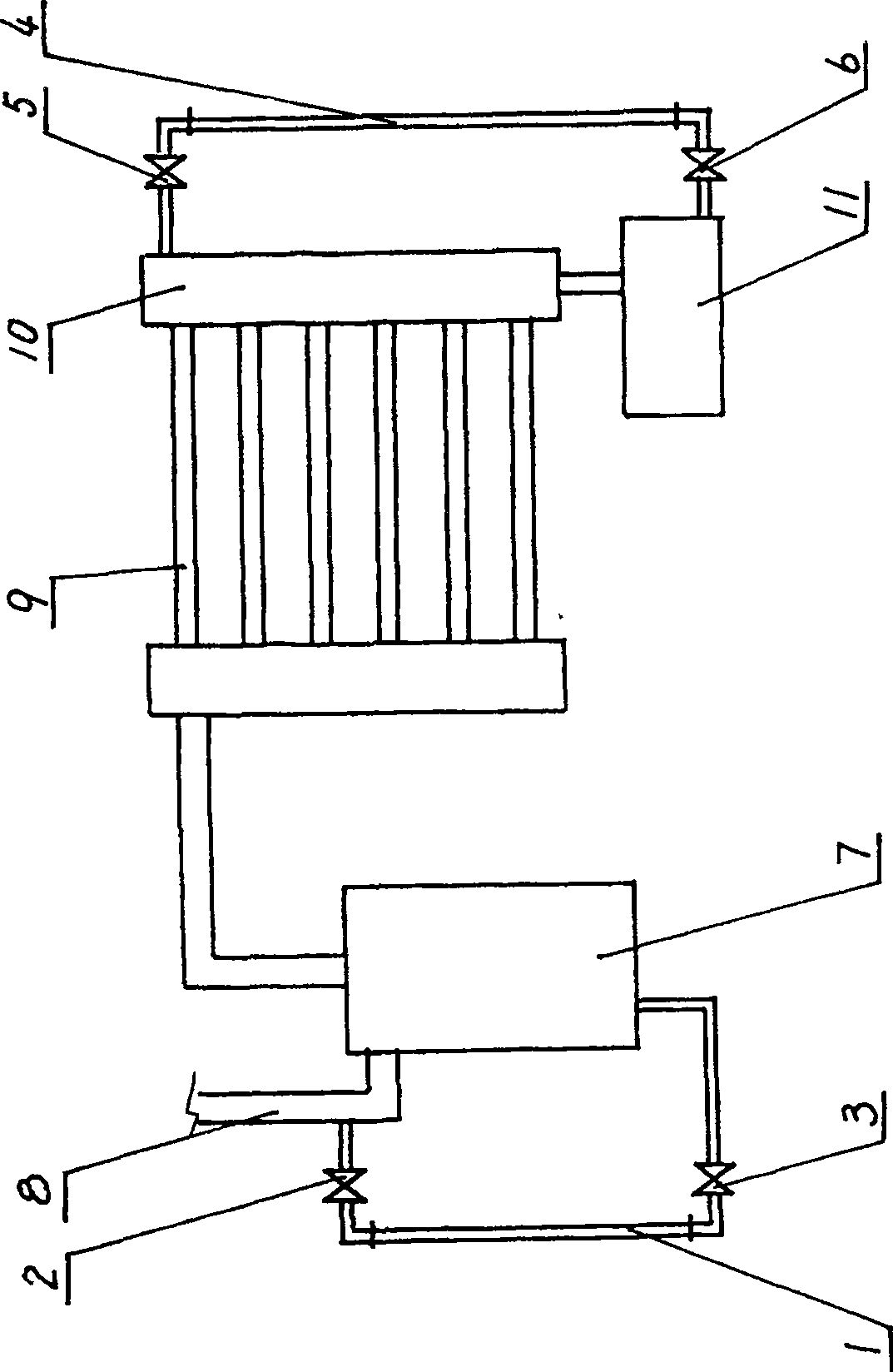

[0013] In this embodiment, the oil level pipe 1 of the present invention is used for a single refrigeration compressor unit 7. The upper valve I2 at the upper end of the oil level pipe 1 communicates with the return air pipe 8 of the refrigeration compressor unit 7 through a metal pipe, and the lower valve at the lower end of the oil level pipe 1 I2 communicates with the bottom of the oil tank of the refrigeration compressor unit 7 through metal pipes.

Embodiment 3

[0015] In this embodiment, the liquid level pipe 4 of the present invention is used for the condenser 9 of a single refrigeration compressor unit 7, and the upper valve II5 at the upper end of the liquid level pipe 4 communicates with the liquid collector 10 of the condenser 9 of the refrigeration compressor unit 7 through a metal pipe. , the lower valve II6 at the lower end of the liquid level pipe 4 communicates with the bottom of the liquid reservoir 11 of the refrigeration compressor unit 7 through a metal pipe.

Embodiment 4

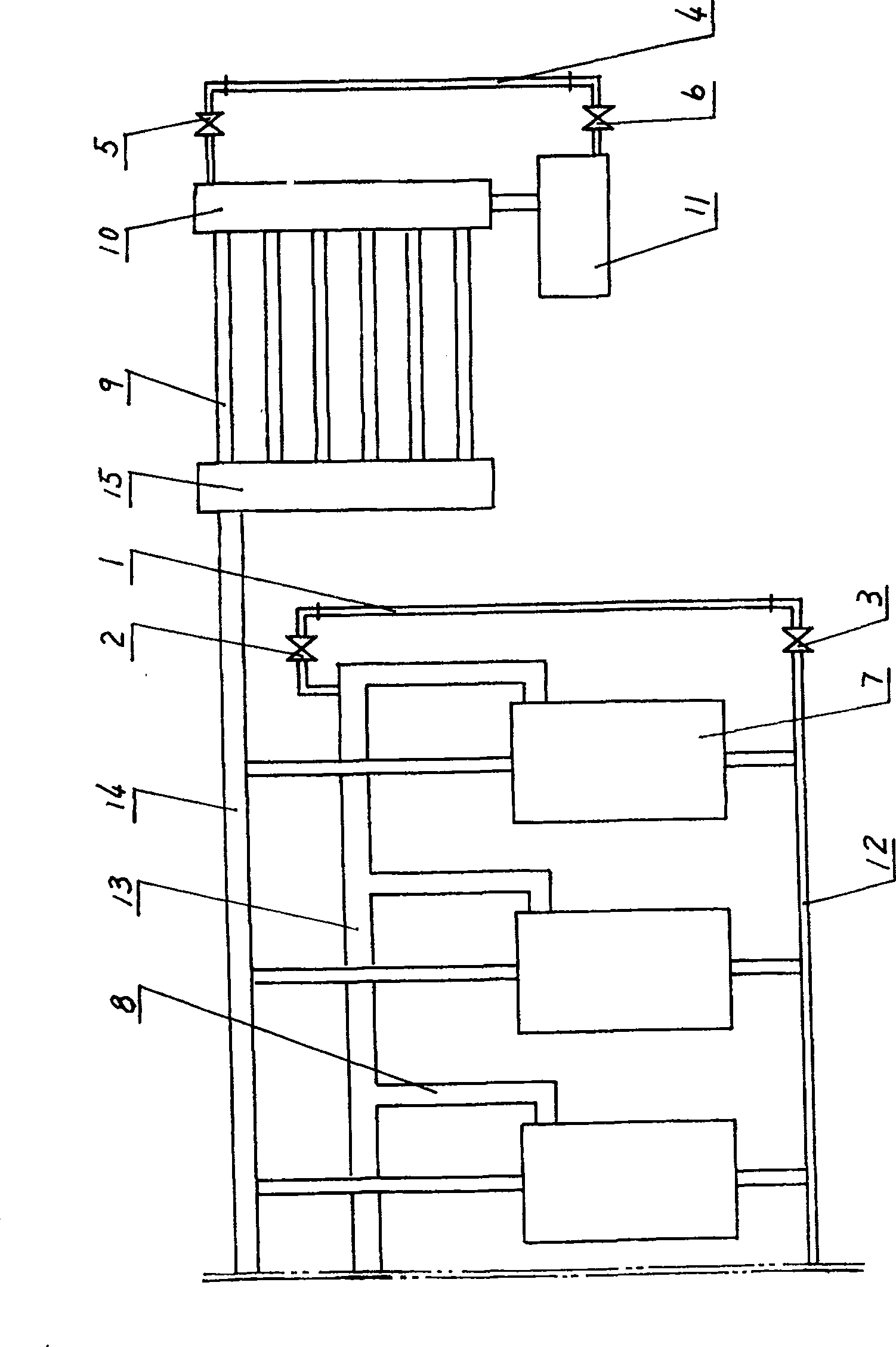

[0016] Embodiment four (see attached figure 2 )

[0017] This embodiment is that the present invention is used for multiple parallel refrigeration compressor units 7. Generally, when a cold store uses multiple parallel refrigeration compressor units 7, its condenser 9 is still one, and multiple parallel refrigeration compressor units 7 pass through The gas header 14 communicates with the gas distribution pipe 15 of the condenser 9 . At this moment, the bottoms of the oil passages of multiple refrigeration compressor units 7 can be communicated with the connecting oil pipe 12, and the air return pipe 8 is communicated with the return air manifold 13; The communication of the gas header 13, the lower valve I3 at the lower end of the oil level pipe 1 communicates with the communication oil pipe 12 at the bottom of the oil circuit of the refrigeration compressor unit 7 through a metal pipe. The upper valve II5 at the upper end of the liquid level pipe 4 communicates with the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com