Minisize ultrasonic transducer with flexible base plate

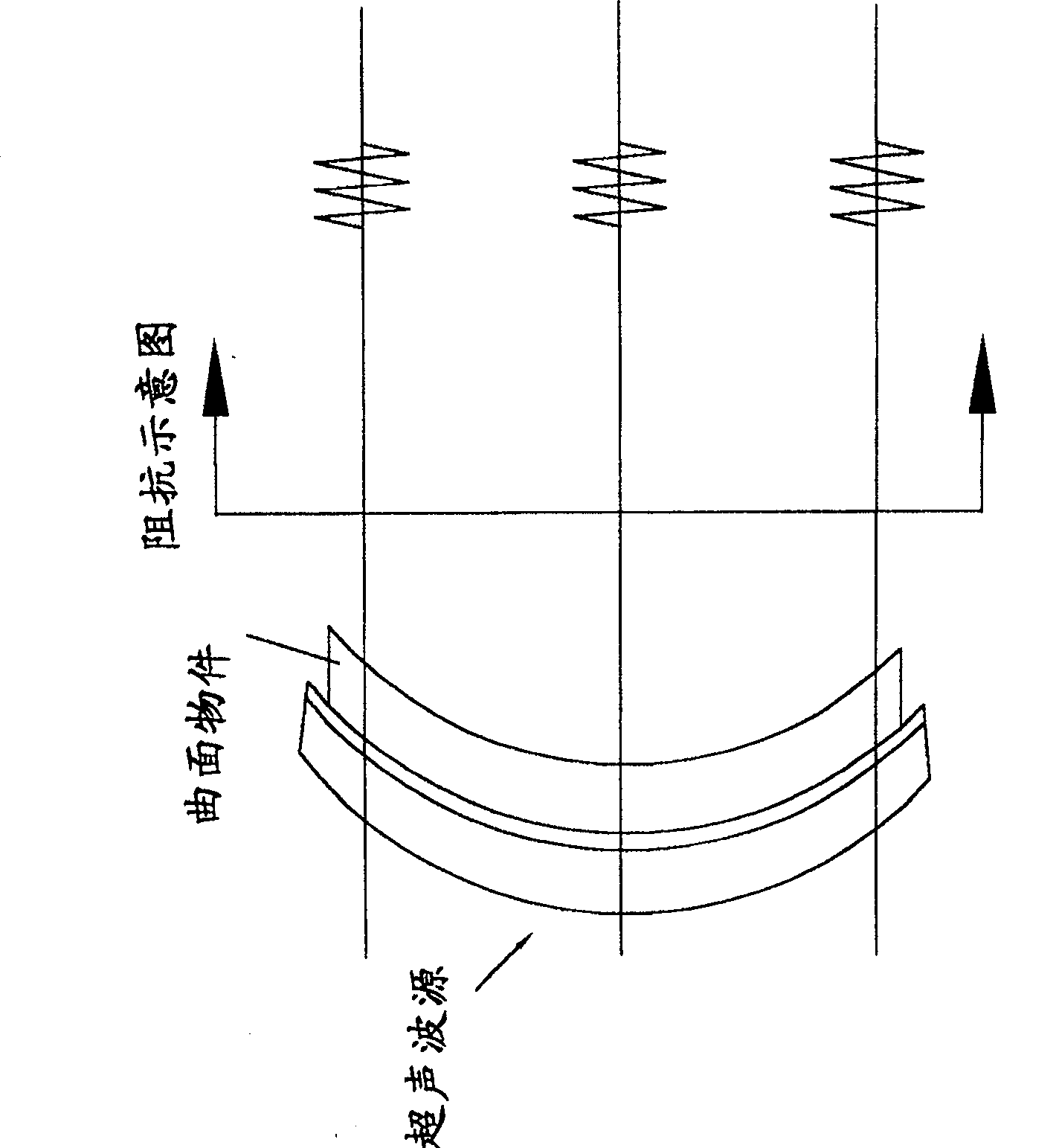

An ultrasonic and transducer technology, applied in the field of miniature ultrasonic transducers, can solve the problems of reducing the resolution and characteristics of components, increasing the attenuation coefficient of components, and unable to produce flexible deformation, so as to achieve improved sensing sensitivity and efficiency, Reduce the effect of impedance and matching layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

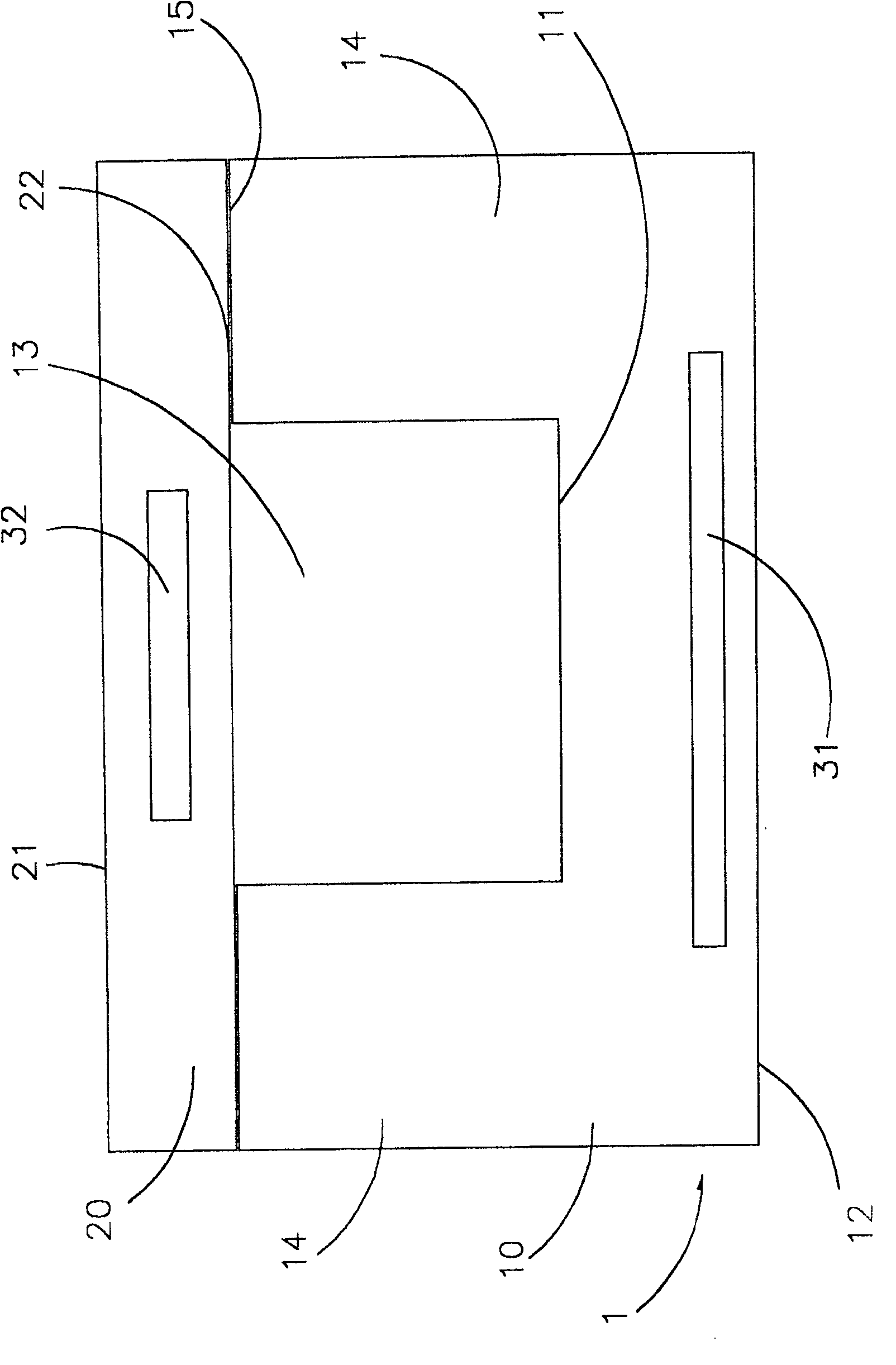

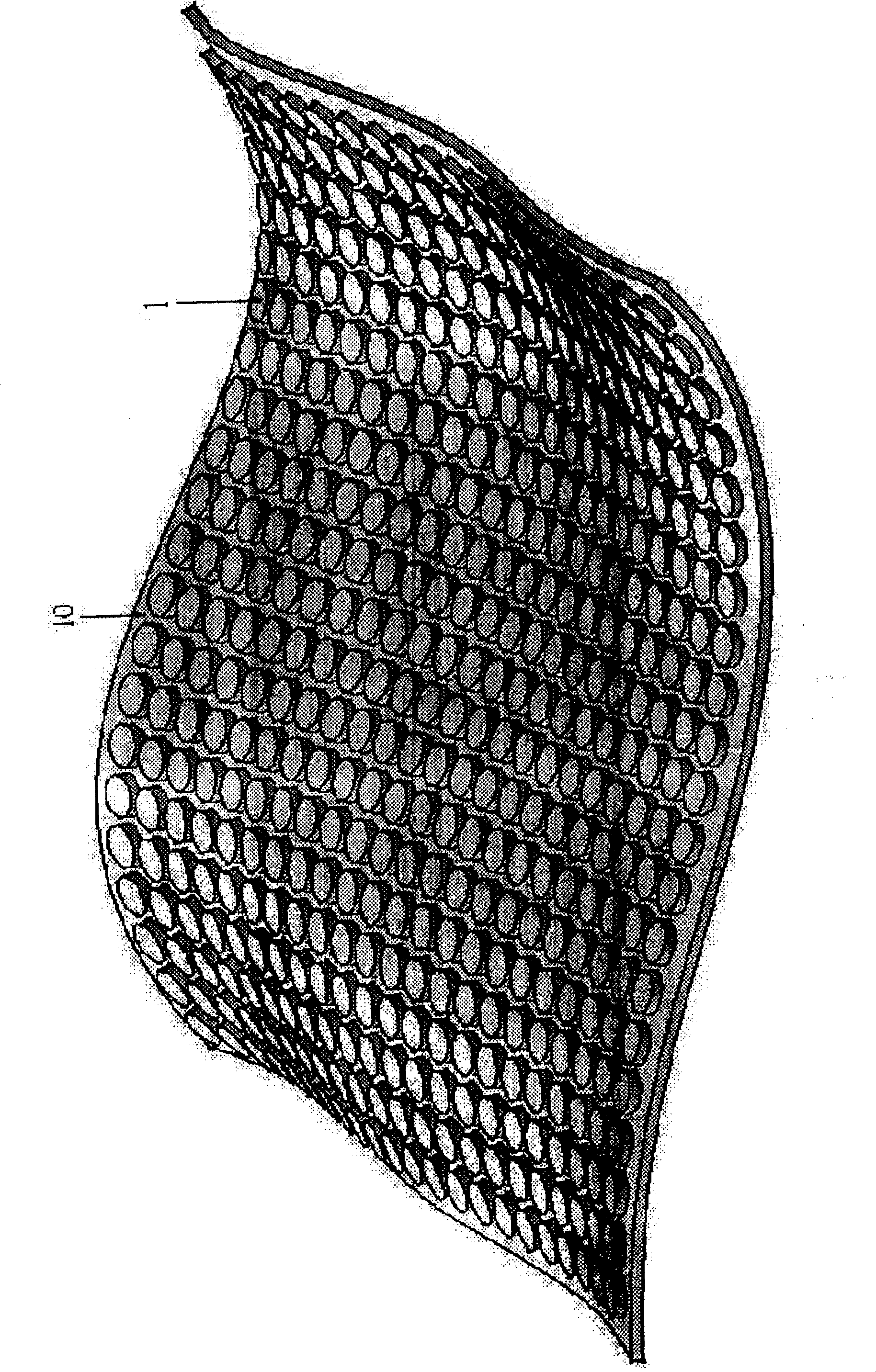

[0029] Such as Figure 1~2 As shown, the micro ultrasonic transducer unit 1 includes a substrate 10, an oscillating film 20, a plurality of first electrodes 31 and second electrodes 32, and the micro ultrasonic transducer is composed of a plurality of micro ultrasonic transducer units 1. , Where: a substrate 10 is made of flexible material, on which is provided a first surface 11 and a second surface 12; the upper end of the first surface 11 is formed with a groove 13, and on both sides The support 14 can be made of a flexible material or a non-flexible material. The materials of the substrate 10, the support 14 and the oscillating film 20 are Silicone (silicone) Si3N4 (silicon nitride) Polysilicon (polysilicon), kapton, Ni( Nickel) Telflon (Teflon), resin, plastic, polyester, polyimide, photoResist (photoresist) or polymer materials, etc., wherein the bracket 14 and the substrate 10 can also be integrated with the same material, which also belongs to the scope of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com