Acidic soy protein gel foods and preparation method thereof

A soybean protein, acidity technology, applied in vegetable protein processing, food science, food preparation, etc., can solve the problems of no production, no method of forming a gel of soybean protein, weak solubility of soybean protein, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

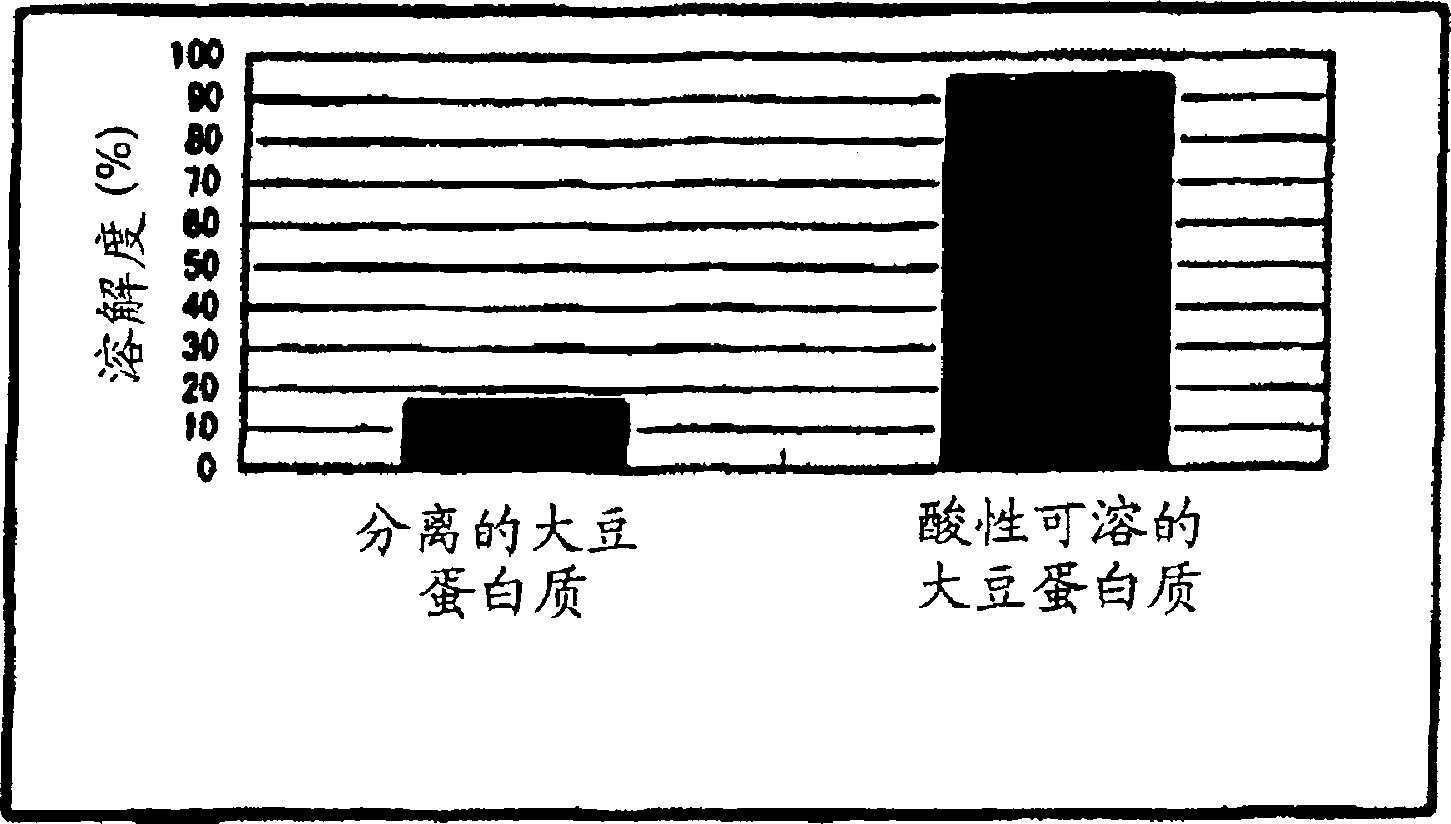

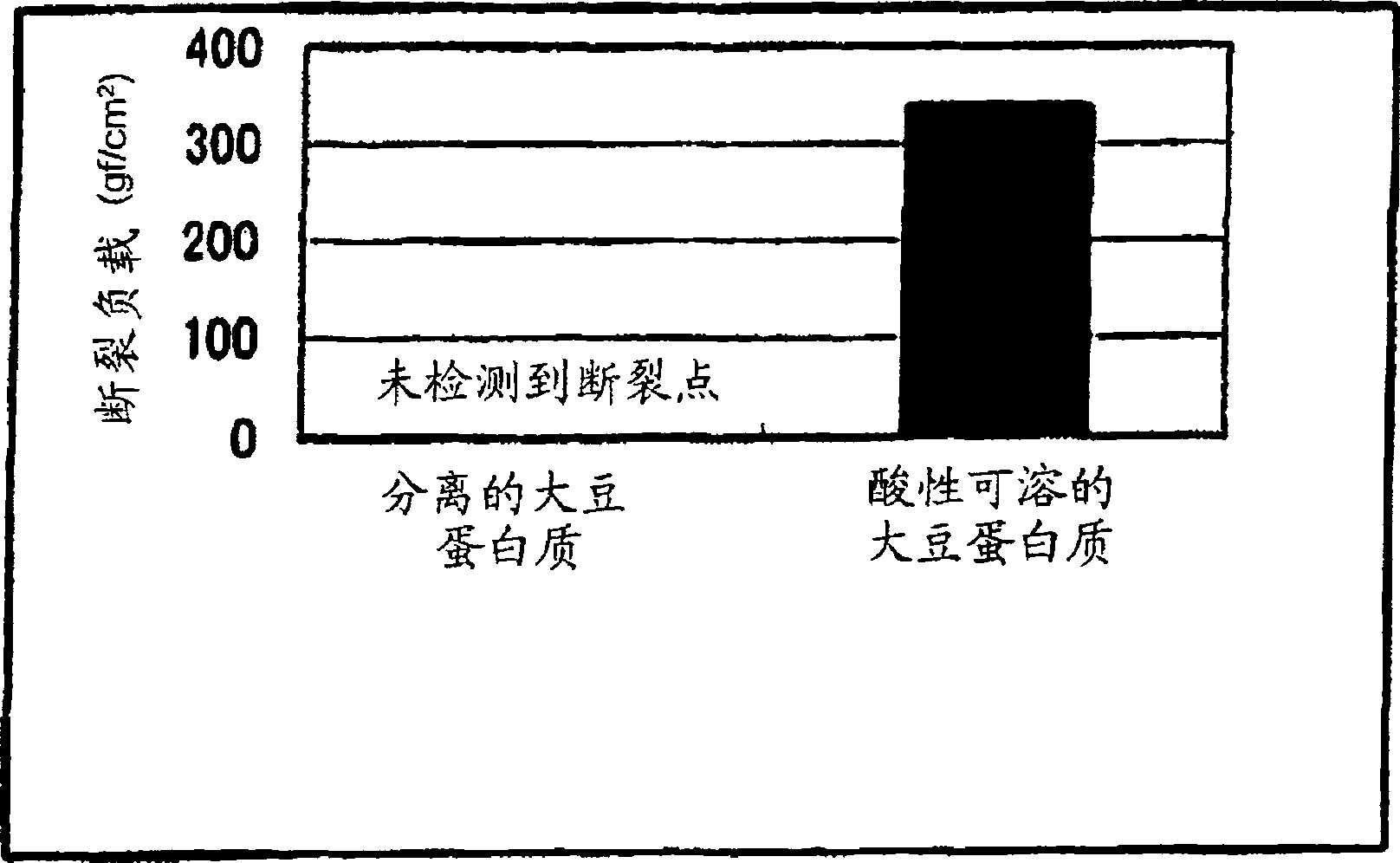

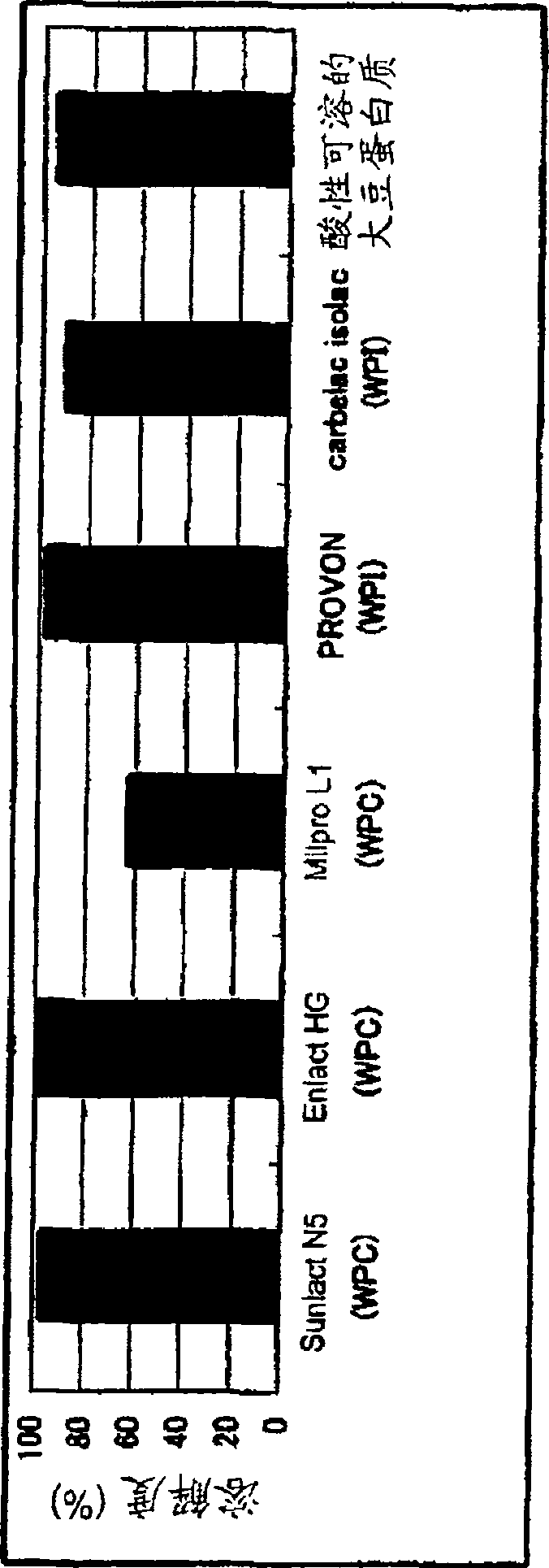

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1: high concentration gel

[0079] The acid-soluble soybean protein obtained in the above preparation example was cut with a food cutter to prepare a paste having a solid content of 14% by weight. To the paste was added 0.03% sucralose (San-Ei Gen F.F.I., Inc.) and 0.2% Orange Flavor (International Flavors & Fragrances Inc.) and the mixture was homogenized and defoamed. The mixture was placed in a heat-resistant container, and then heated at 80° C. for 30 minutes in a thermostat. The resulting gel treat was clear and the texture was suitably springy and desirable.

Embodiment 2

[0080] Example 2: pH adjustment and salt addition

[0081] The aqueous acid-soluble soybean protein solution (solid content: 9% by weight) obtained in the above Preparation Example was adjusted to pH 3.75 with 20% sodium hydroxide solution and sodium chloride was added to the solution so that the concentration was 50 mM. To the mixture were added 0.03% sucralose (San-EiGen F.F.I., Inc.) and 0.2% blueberry flavor (International Flavors & Fragrances Inc.). The mixture was stirred to obtain a homogeneous mixture, placed in a heat-resistant container, and then heated in a thermostat at 80°C for 30 minutes. The resulting gel food had a transmittance of 40%T and was clear. The gel food can be made spoonable and has sufficient shape-holding properties and proper elasticity.

Embodiment 3

[0082] Embodiment 3: adding of weak acid salt

[0083] The aqueous acidic soluble soybean protein solution (solid content: 12% by weight) obtained in the above Preparation Example was adjusted to pH 4 with sodium citrate and 0.02% sucralose (San-Ei Gen F.F.I., Inc. ) and 0.2% muscadine flavor (International Flavors & Fragrances Inc.). Stir the mixture to obtain a homogeneous mixture, place it in a heat-resistant container, and then heat it in a thermostat at 80°C for 1 hour to obtain a breaking load of 120gf / cm 2 gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com