Method and device for sticking tape

A sticking device, sticking roller technology, applied in the direction of bonding methods, adhesives, transportation and packaging, etc., can solve the problem of wafer warping and deformation that has not been completely solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

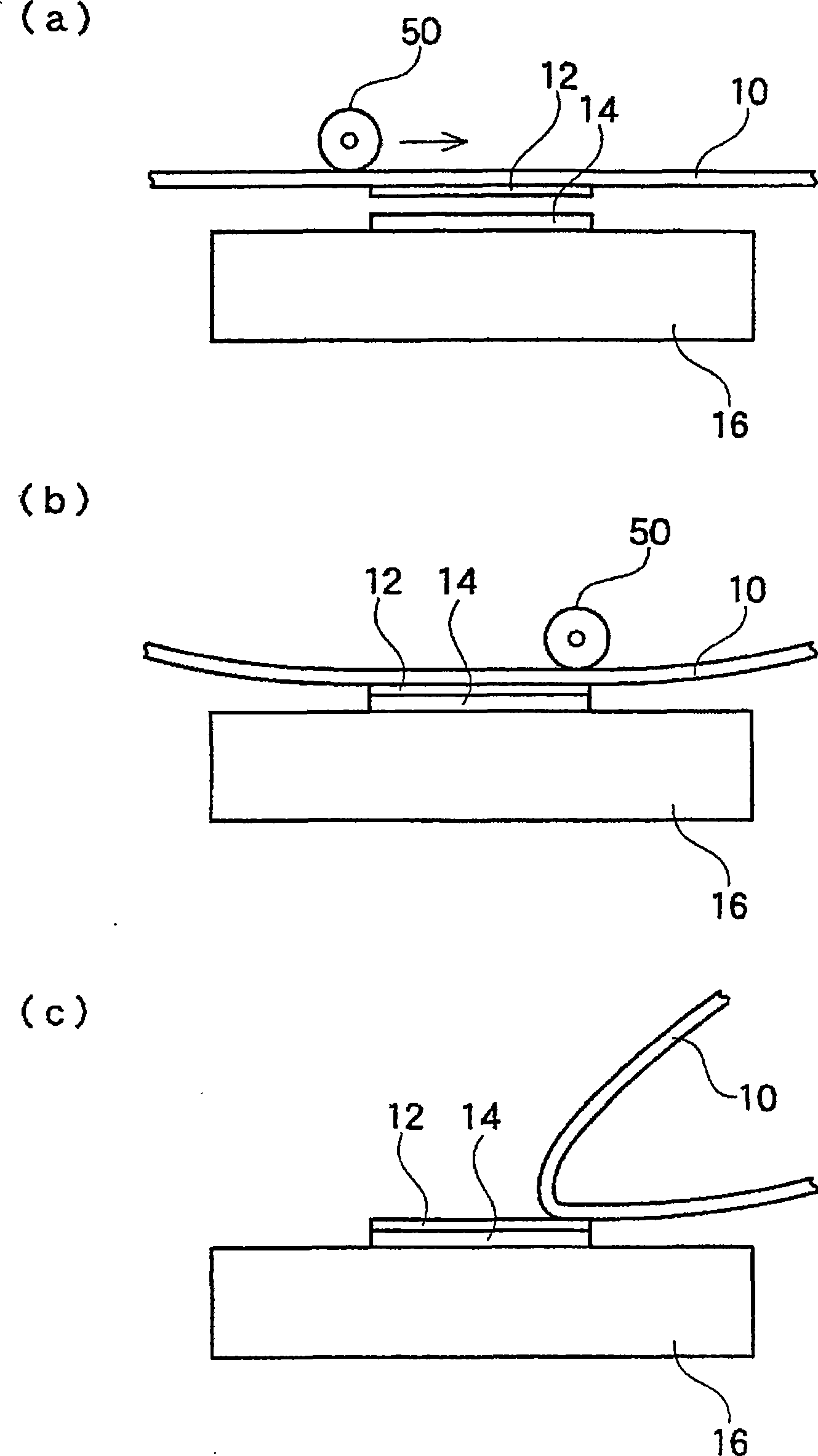

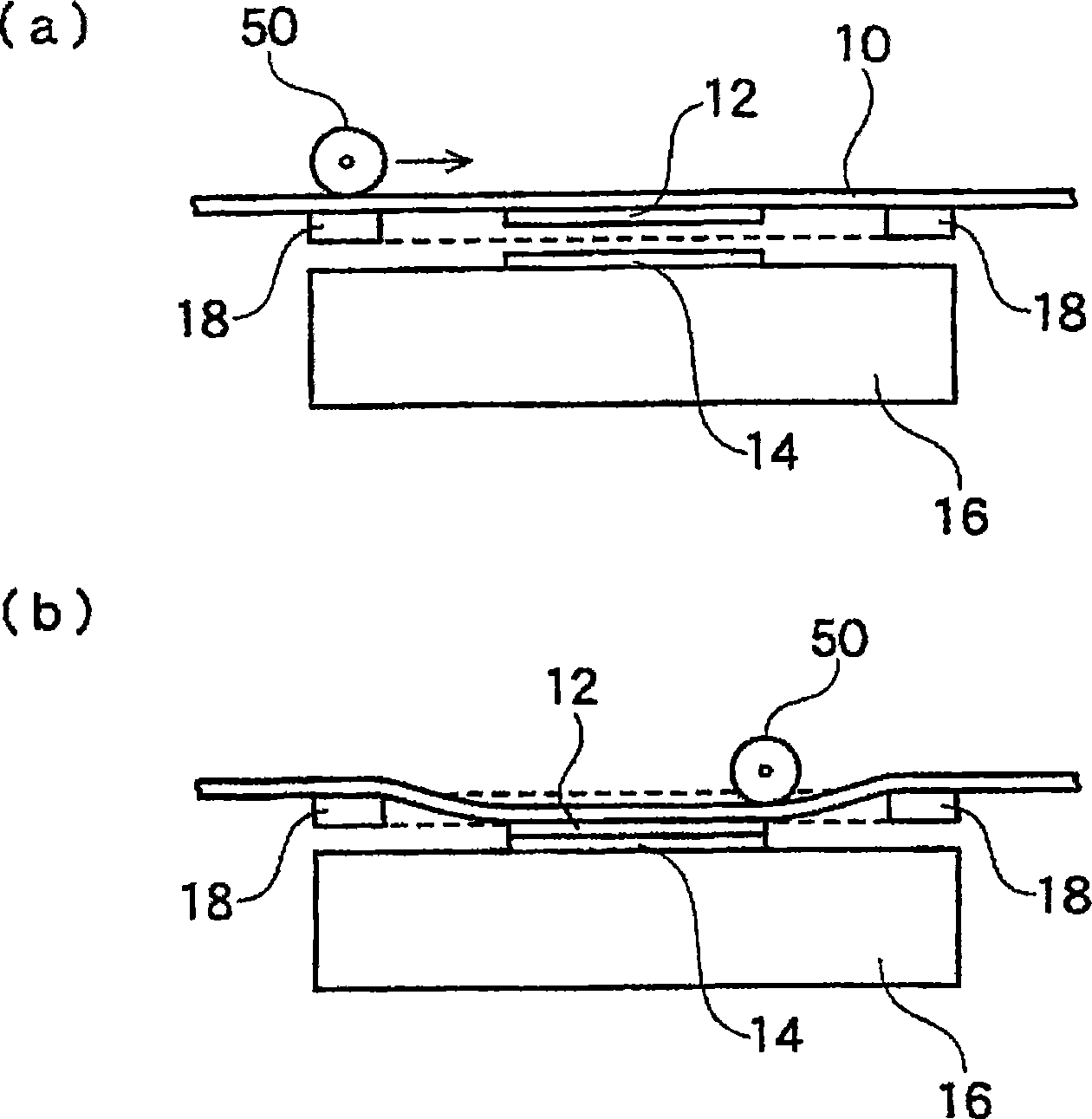

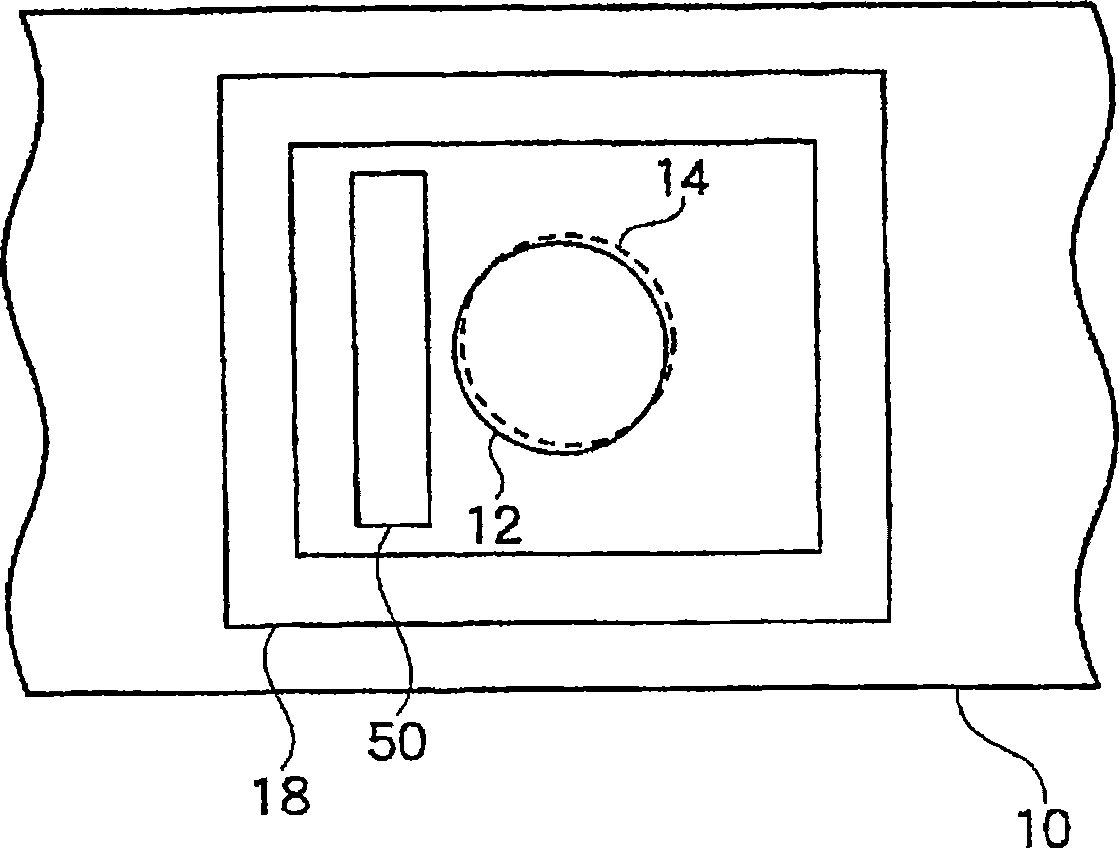

[0107] Embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 is a set of front views for illustrating the paste operation according to the method of the present invention. figure 2 is a set of front views involving the gluing of frame members for illustrating the method according to the invention. image 3 for figure 2 top view.

[0108] Such as figure 1 As shown, a tape having a size corresponding to the adherend 14 is prepared in advance, and by sticking the tape on the support film 10 , the support film is pressed to stick the tape 12 to the adherend 14 .

[0109] When the tape is attached to the adherend 14, the supporting film remains in a flat state with tension ( figure 1 (a)). In this state, the tape 12 affixed to the support film 10 remains under less tension as the tension is maintained on the thick laminate of the support film 10 and tape 12 and diffuses into the support film 10 .

[0110] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com