Pin shaft milling special-purpose milling machine

A special milling machine, milling technology, applied in milling machine equipment, milling machine equipment details, large fixed members, etc., can solve the problems of cumbersome operation, low work efficiency, backward design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

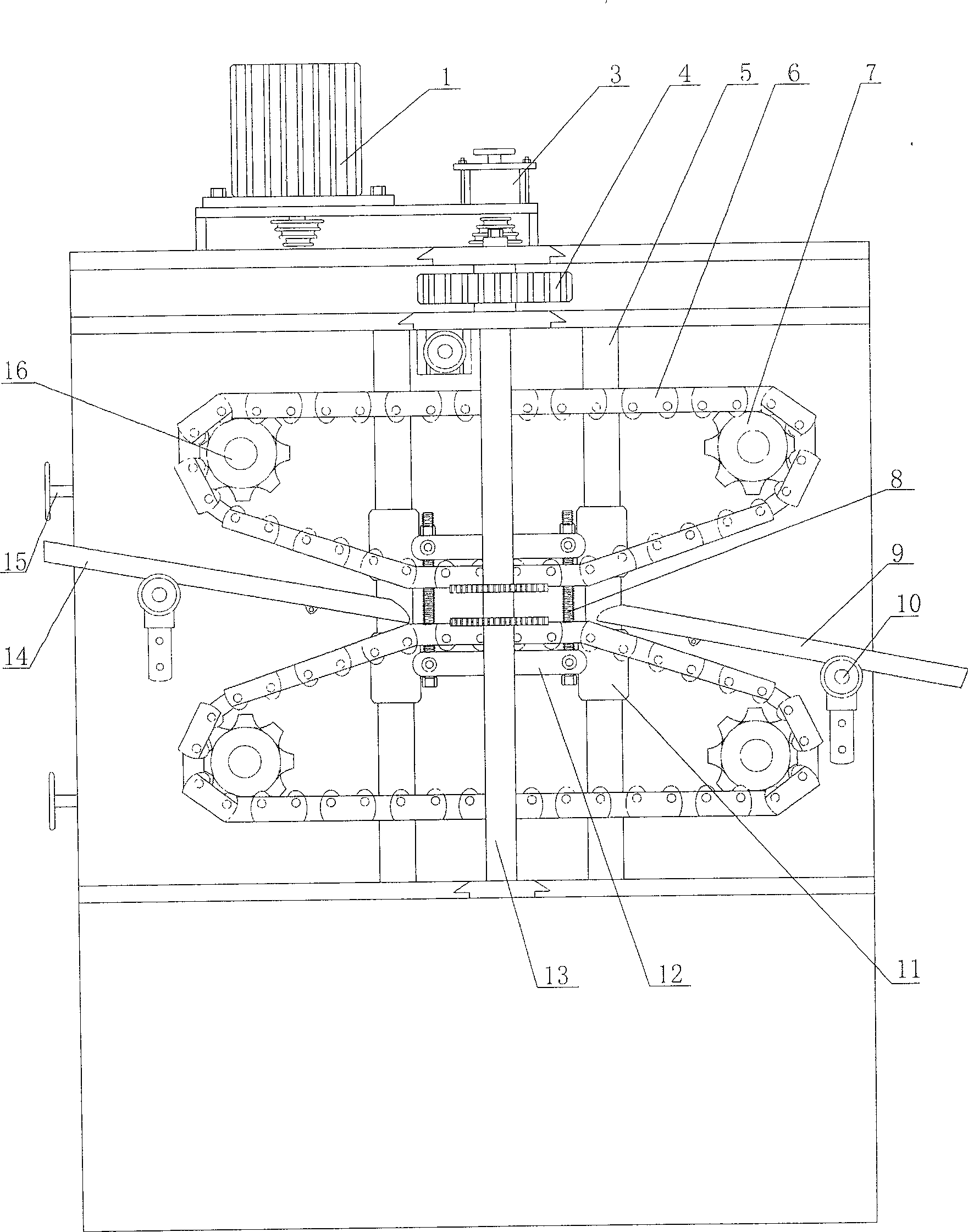

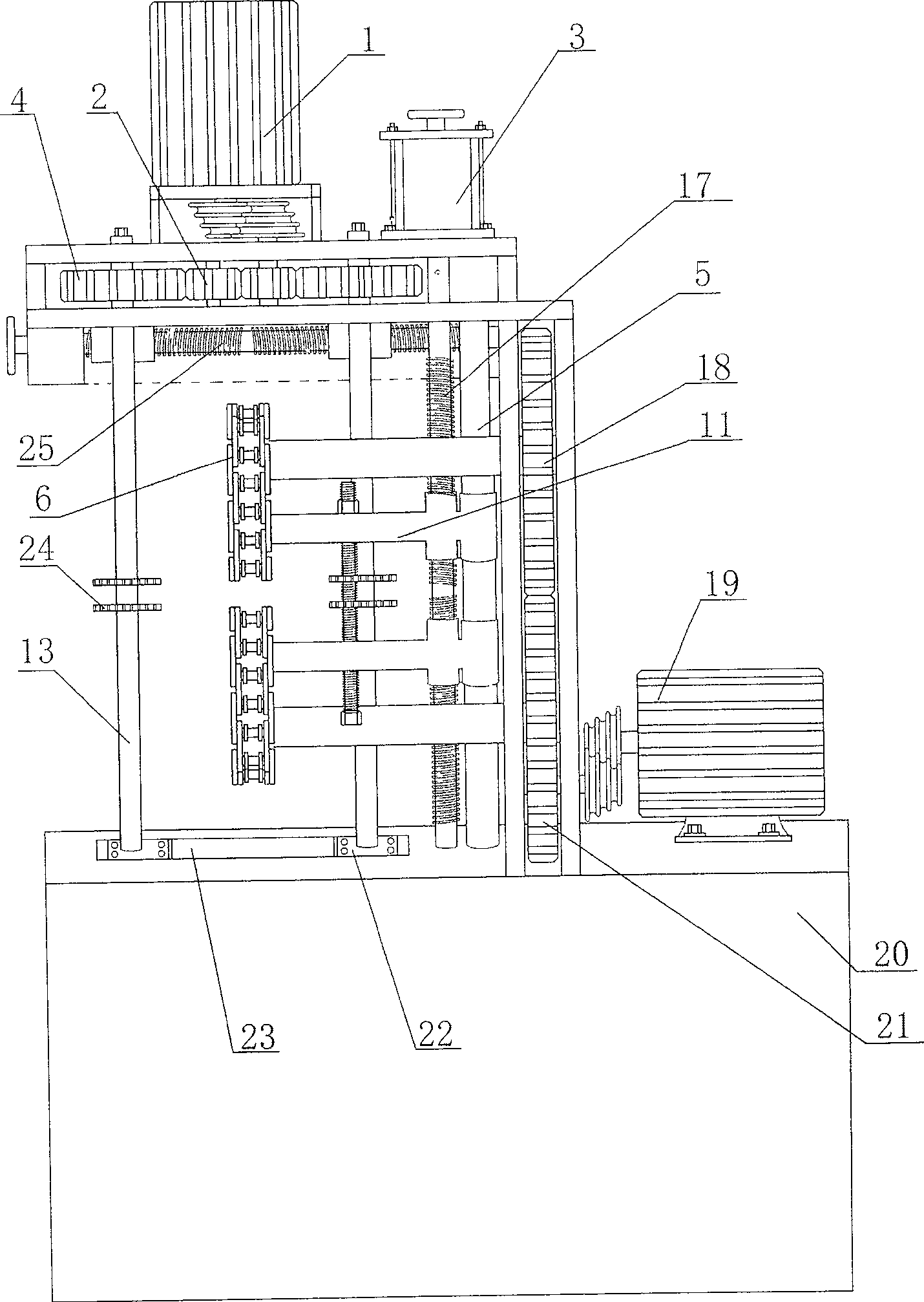

[0011] Such as figure 1 , 2 A special milling machine for pin shaft milling is shown, which mainly includes a bed 20, a positioning feeder 14, a positioning discharger 9, a chain clamp transmission device, a guide rail clamp locking transmission device, and a double-spindle cutter bar transmission device , the chain clamp transmission device includes a motor 19 through a belt drive pinion 21, the pinion drives the meshed main sprocket coaxial bull gear 18, and the main sprocket coaxial coaxial bull gear is coaxially connected to a group of spaced apart main gears. Sprocket 7, the main sprocket drives the auxiliary sprocket 16 through the chain clamp 6, and the auxiliary sprocket adjusting screw 15 adjusts the distance between the auxiliary sprocket 16 and the main sprocket 7, controls and locks the tightness of the chain clamp, and the auxiliary chain The outside of wheel 16 is equipped with location feeder 14, and the outside of main sprocket 7 is equipped with location feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com