Resin molding machine

A molding machine and resin technology, applied in the coating and other directions, can solve the problem of increasing the number of residual materials, and achieve the effect of reducing the scope, reducing the cost, and simplifying the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

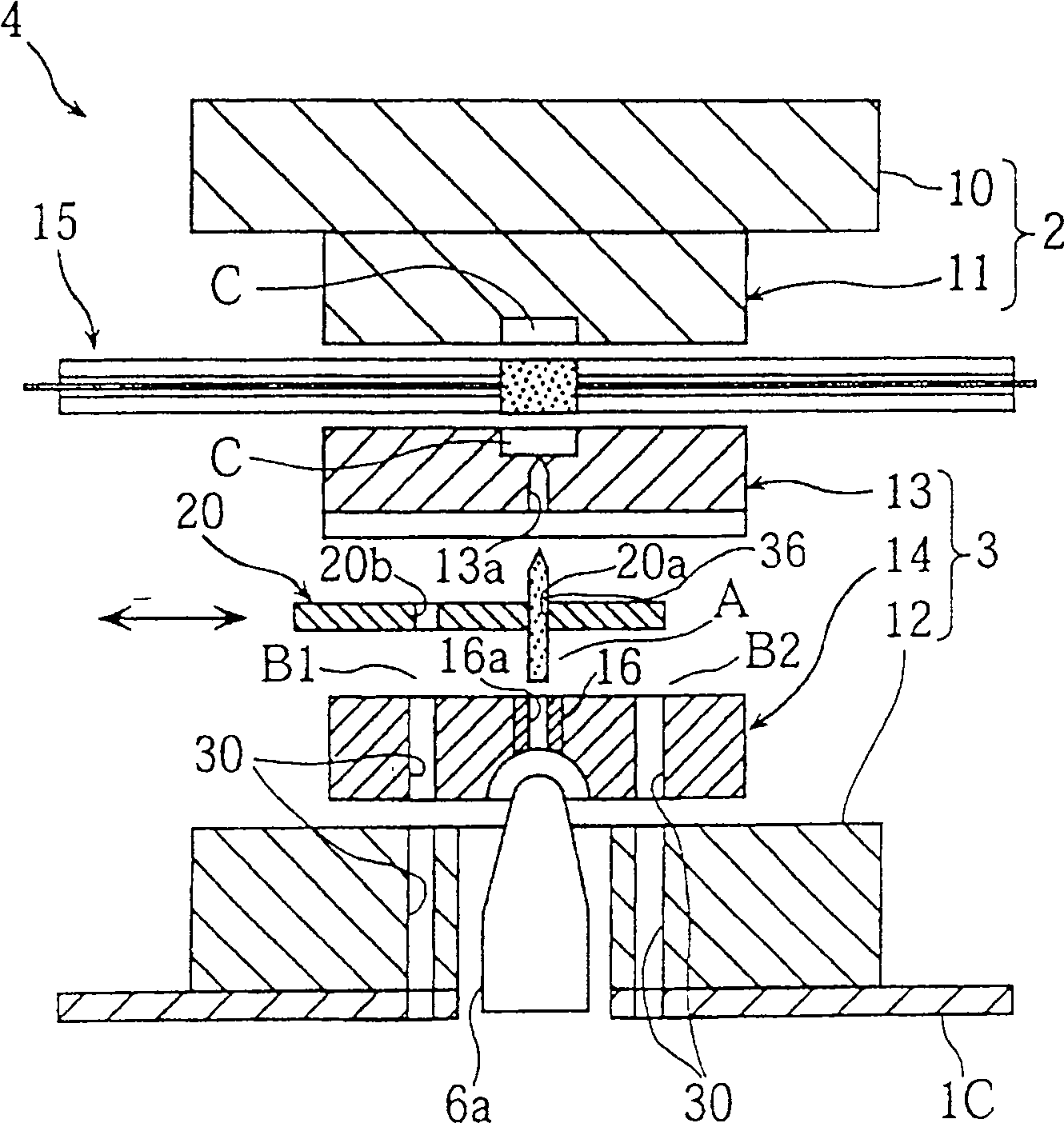

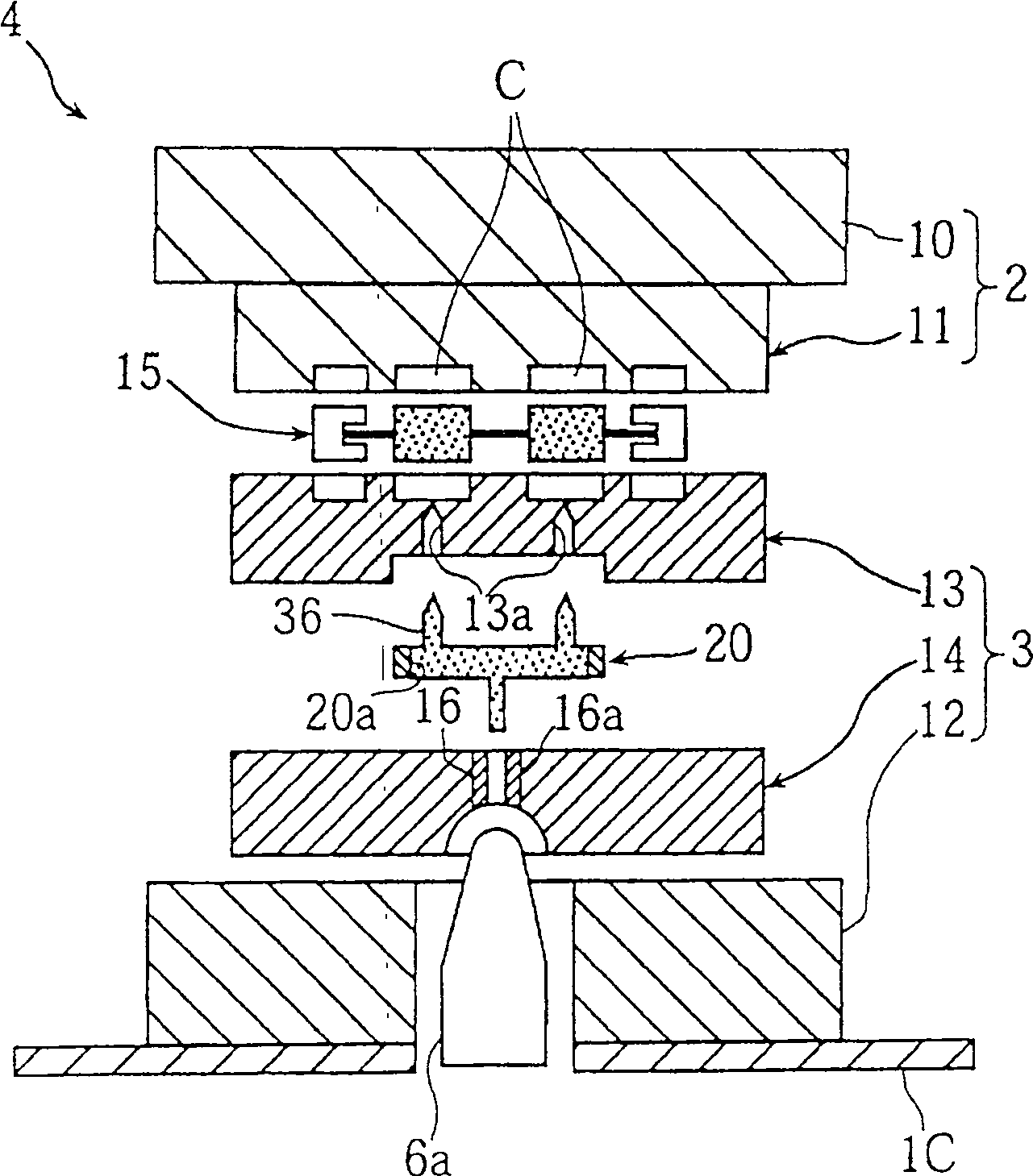

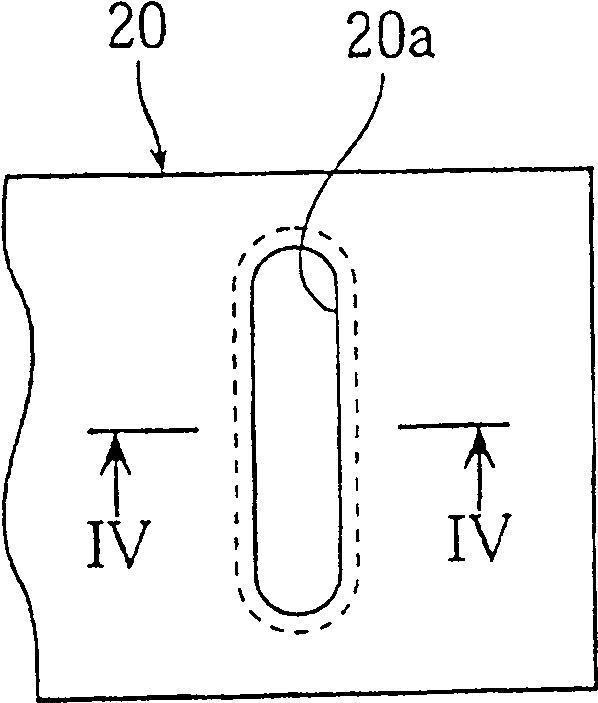

[0049] Figures 1 to 9 A resin molding machine is shown. Figures 1 to 2 are a front sectional view and a side sectional view showing a mold in an open state, respectively. image 3 and 4 Respectively, a plane view and a section view of the channel plate ( image 3 section IV-IV). Figure 5 and 6 is a schematic diagram showing a drive unit of the flow channel plate. Figure 7 This is an overview of the resin molding machine. Figure 8 (a) to (d) and Figure 9 (e) to (g) show a molding process using the mold.

[0050] In these figures, reference numeral 1 denotes a resin molding machine for producing an electronic component made of a thermoplastic resin or a thermosetting resin by injection molding.

[0051] The resin molding machine 1 has a fixed bed 1a on which a mold 4, a mold clamping unit 5, and a molding material delivery unit 6 are provided. The mold 4 includes a movable mold unit 2 and a fixed mold unit 3, The mold clamping unit 5 moves the movable mold unit 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com