Rail-guided transport system

A conveying system and track-guided technology, which is applied in transportation and packaging, electric vehicles, power collectors, etc., can solve complex and expensive problems, and achieve the effects of reducing costs and costs, reducing wear and maintenance costs, and reducing radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

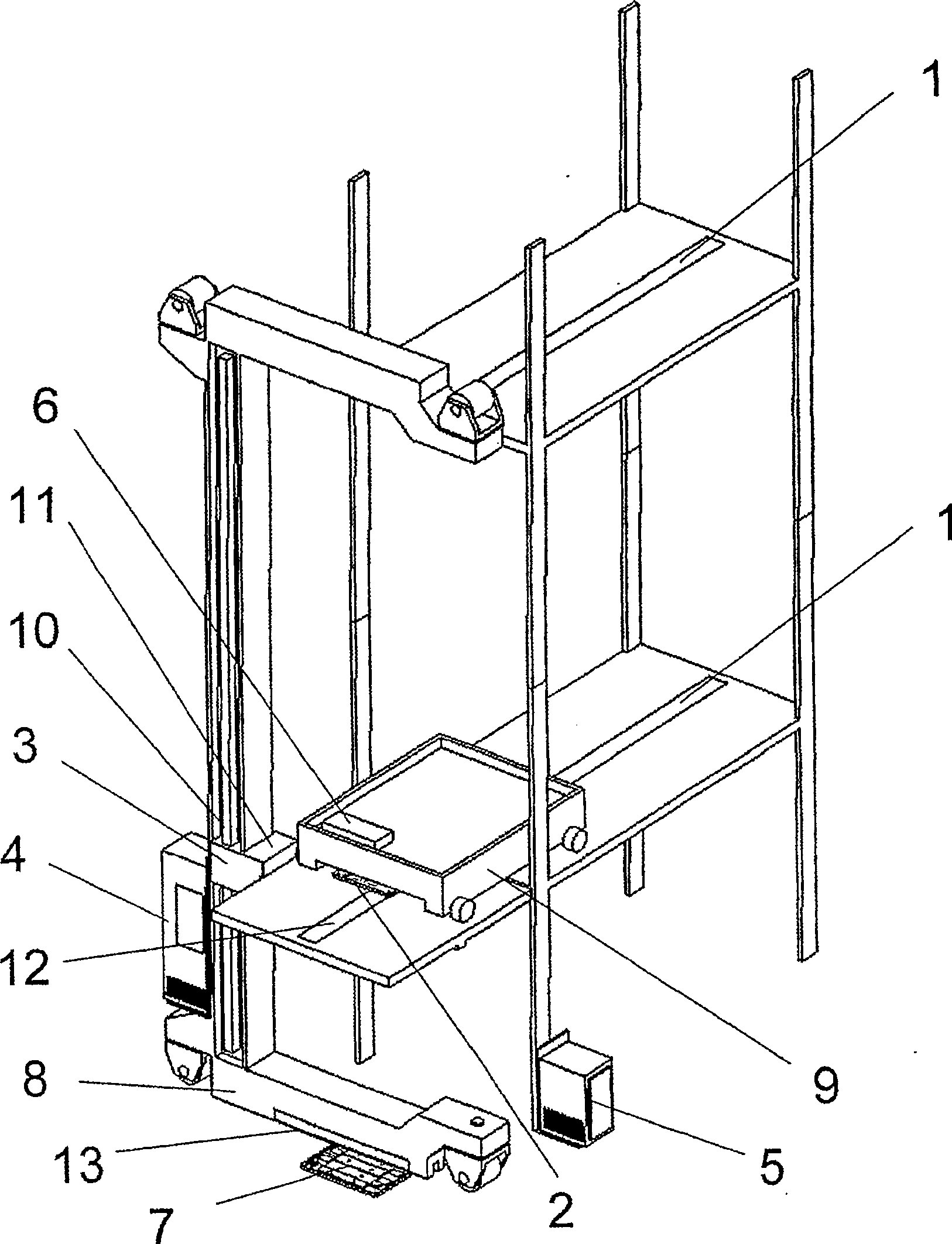

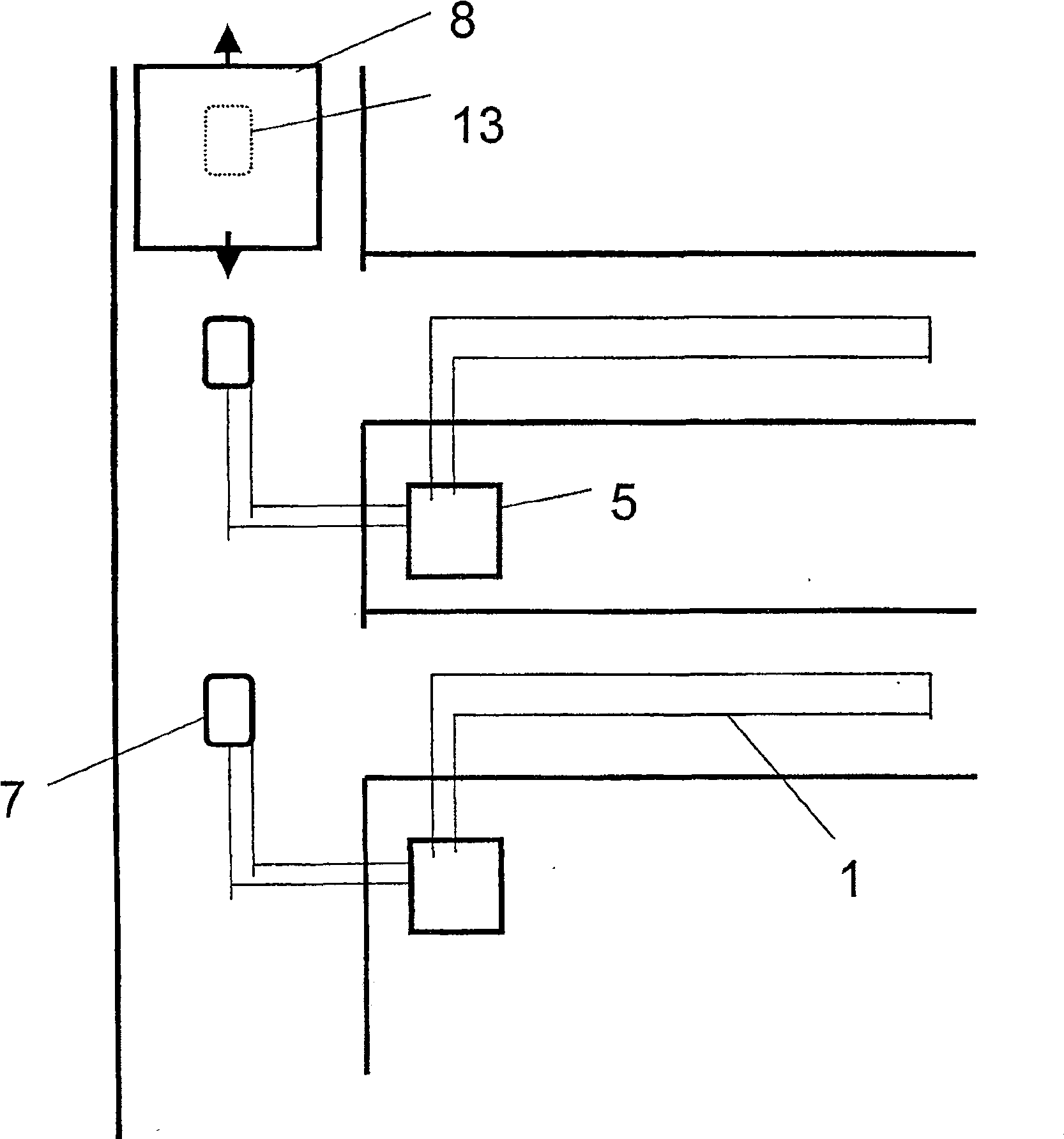

[0036] The invention will be explained in detail below with the aid of the drawings:

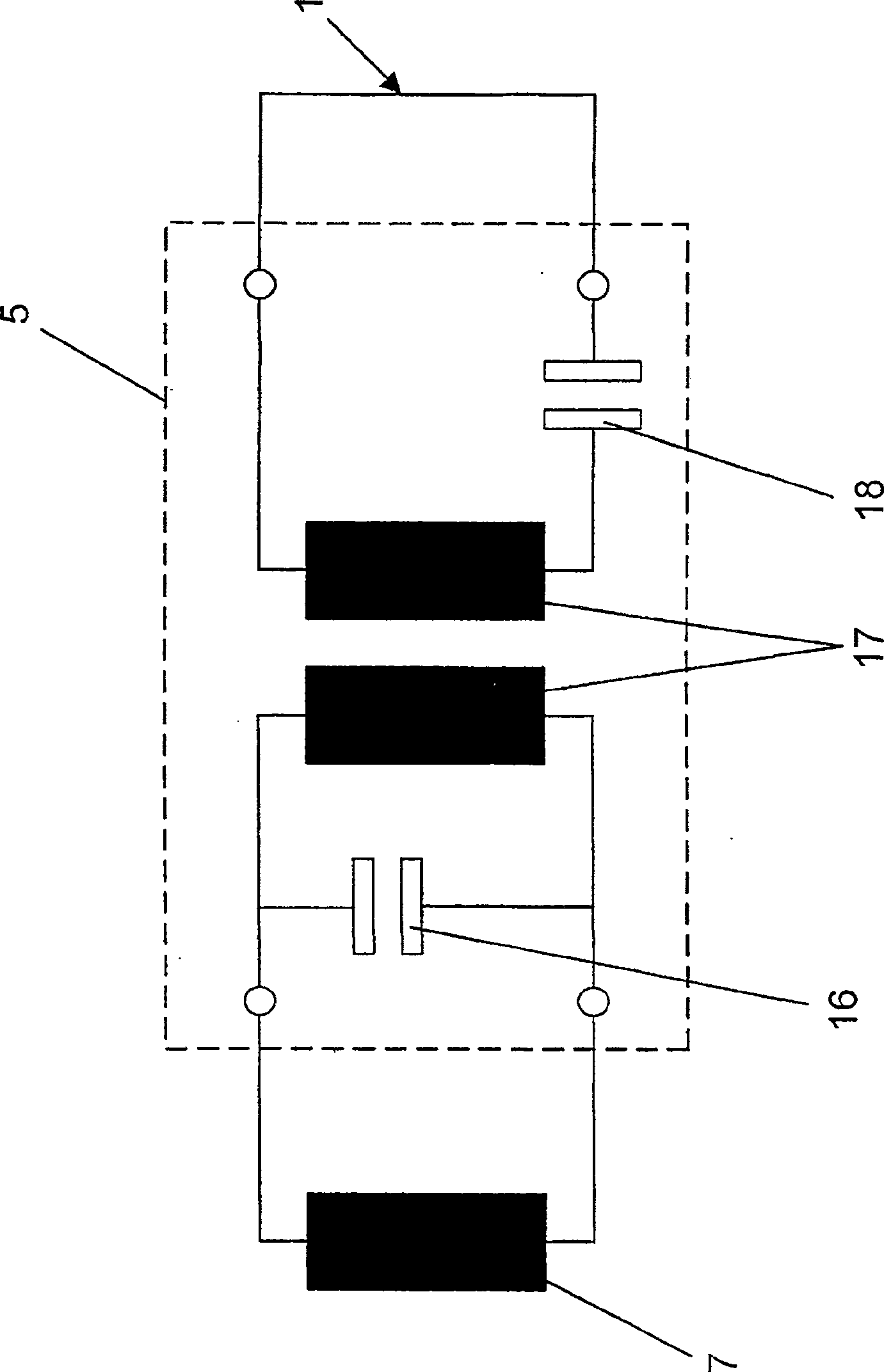

[0037] The present invention includes a system for non-contact energy transmission, as shown in the prior art, where a transmission head including at least one winding is particularly provided on the moving part. The non-moving part of the system includes at least a linear conductor and a loop as the primary conductor. The loop can be arranged in the profile or designed as a straight conductor. The transmission head is inductively coupled with the linear conductor. If the loop is arranged in the profile, the transmission head is designed such that at least its ferrite core at least partially surrounds the linear feeder. Therefore, the transmission head is designed to be U-shaped or C-shaped. The secondary windings—that is, the windings of the transmission head—are arranged around U-shaped or C-shaped branches. If the loop is designed as a straight conductor, the ferrite core is advantageously de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com