Process for enbancing surface by high-pressure water jet-flow

A high-pressure water jet and surface strengthening technology, which is applied in the field of strengthening the surface of metal materials, can solve the problems of complex process method, unsatisfactory surface quality, and complex equipment structure of high-pressure water impact strengthening equipment, and achieves easy digital control and good materials. Surface quality, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Strengthen the 7075T651 aluminum alloy.

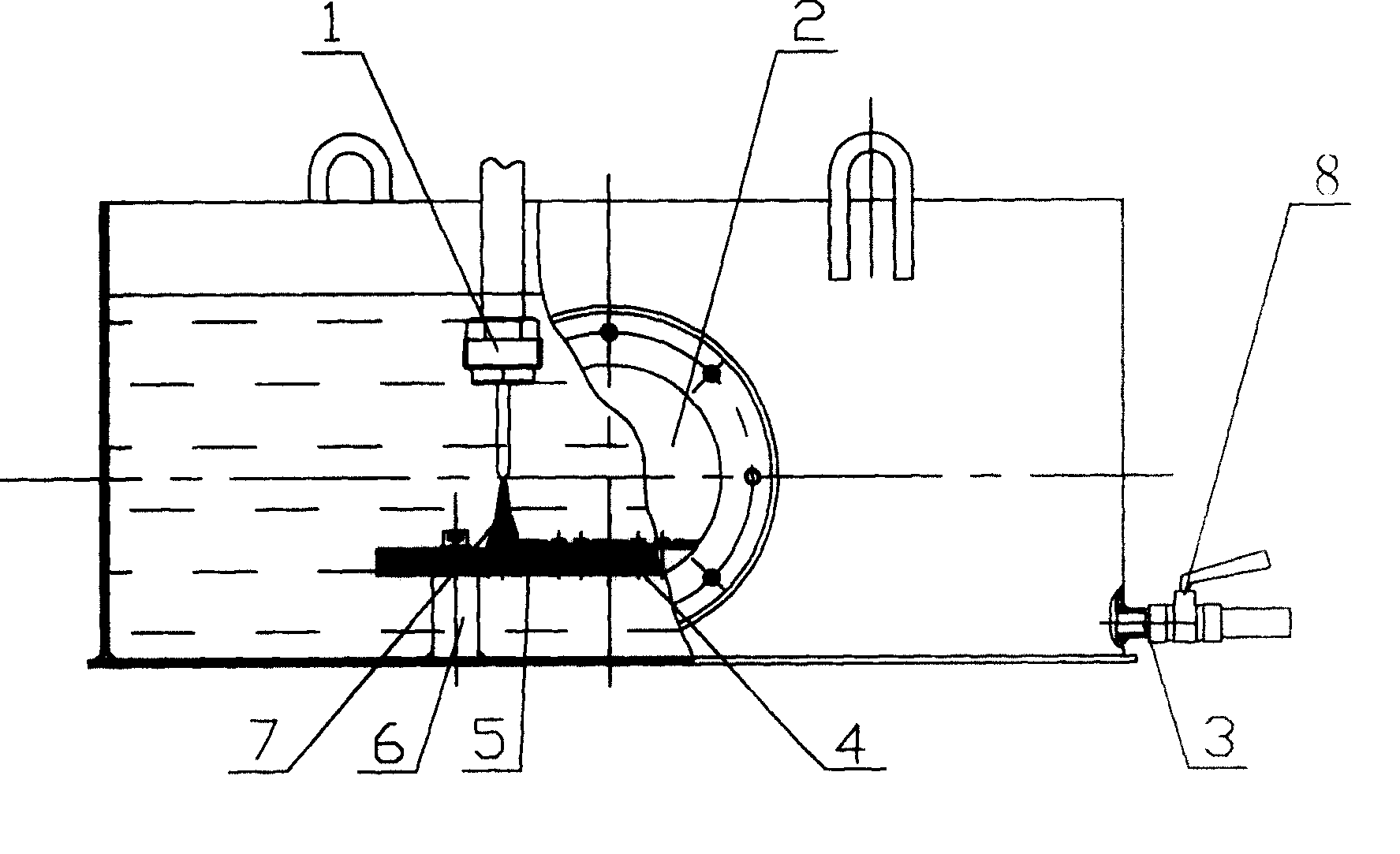

[0028] 1) Place the high-pressure water impact strengthening auxiliary test device (unsealed water tank) on the working table of the two-coordinate high-pressure water cutting machine and adjust it to a suitable position.

[0029] 2) Clamp the test piece on the working platform in the water tank through special fixtures such as the test piece bead, splint, and cushion block to ensure that the position of the test piece is fixed.

[0030] 3) Through the operation on the console of the two-coordinate high-pressure water cutting machine, move the high-pressure water nozzle into the water tank so that the distance from the test piece is 5mm. Close the butterfly valve on the outlet pipe of the water tank, inject water into the water tank, make the water submerge the high-pressure water nozzle, and make the distance between the horizontal plane in the water tank and the nozzle of the high-pressure water nozzle 120mm.

[0031] 4) First adj...

Embodiment 2

[0043] Strengthen the surface of TC4 titanium alloy.

[0044] 1) Place the high-pressure water impact strengthening auxiliary test device (unsealed water tank) on the working table of the two-coordinate high-pressure water cutting machine and adjust it to a suitable position.

[0045] 2) Clamp the test piece on the working platform in the water tank through special fixtures such as the test piece bead, splint, and cushion block to ensure that the position of the test piece is fixed.

[0046] 3) Through the operation on the console of the two-coordinate high-pressure water cutting machine, move the high-pressure water nozzle to the water tank so that the distance from the test piece is 5-10mm. Close the butterfly valve on the outlet pipe of the water tank, and inject water into the water tank so that the water is submerged in the high-pressure water nozzle, and the distance between the horizontal plane in the water tank and the high-pressure water nozzle mouth is 130mm.

[0047] 4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com