General model connecting system of air separation tower and method thereof

A model control, air separation tower technology, applied in the direction of distillation adjustment/control, refrigeration and liquefaction, liquefaction, etc., can solve the problems of not being able to adapt to the dynamic characteristics of air separation operation, not getting good control effect, strong nonlinearity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

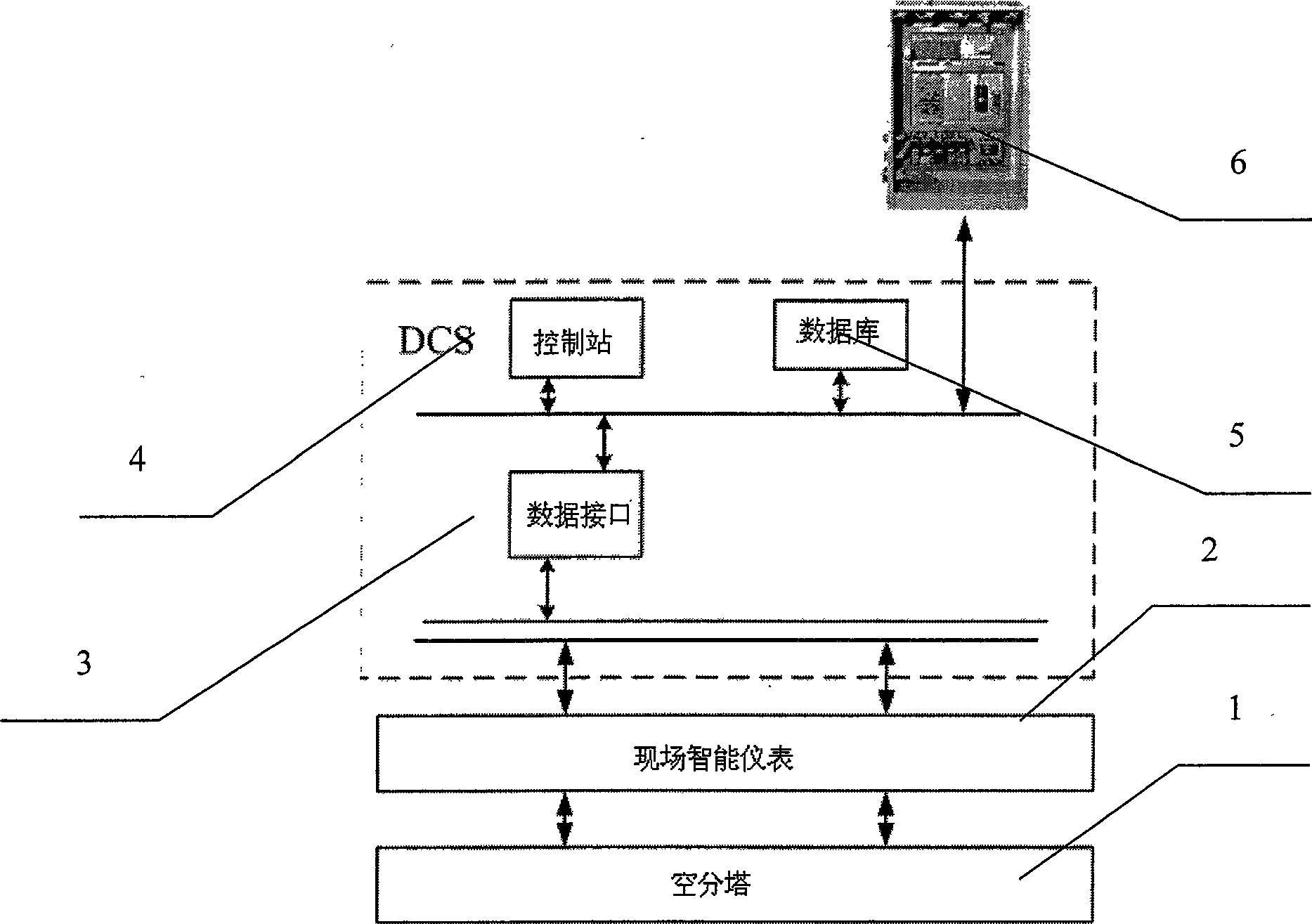

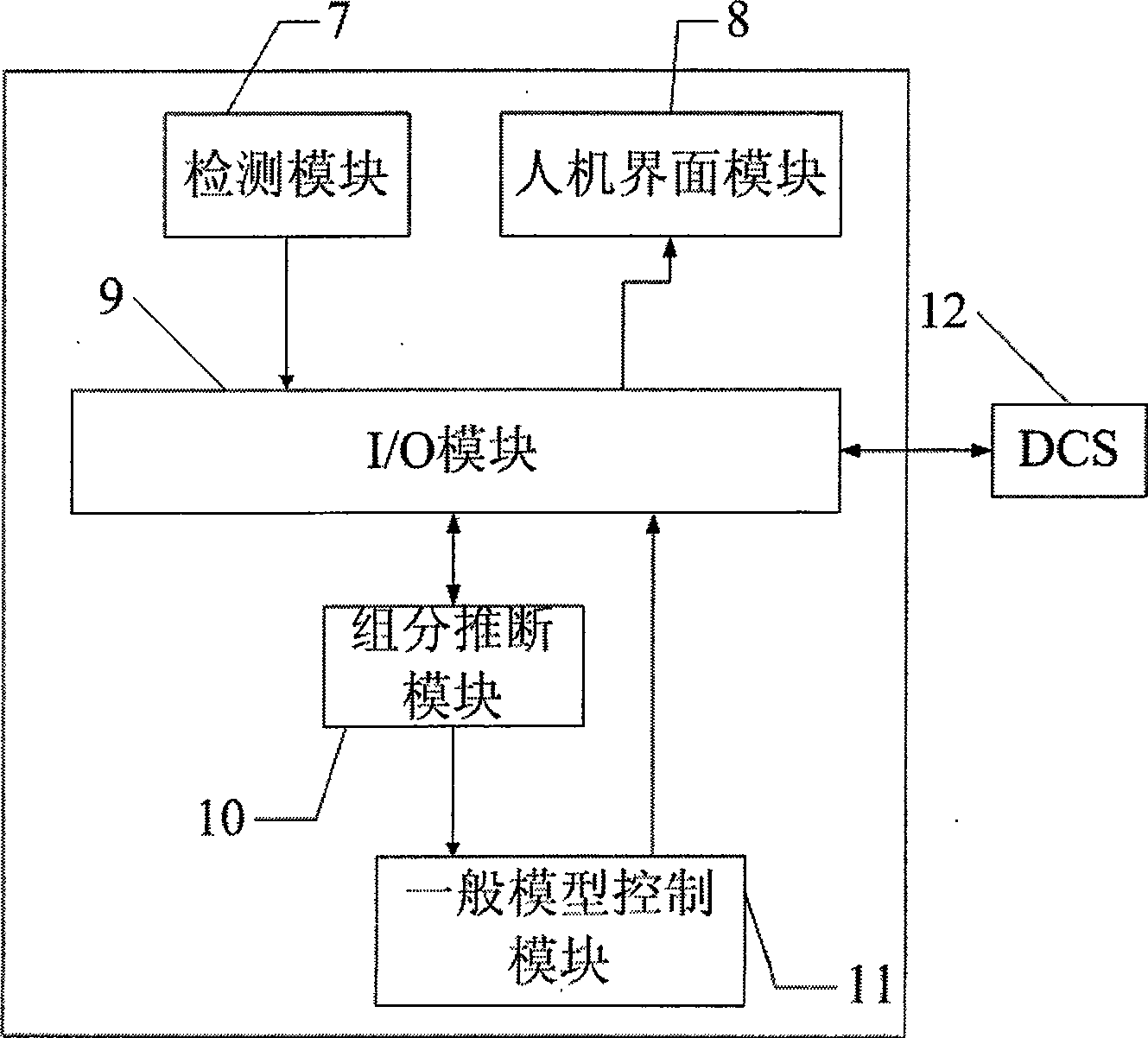

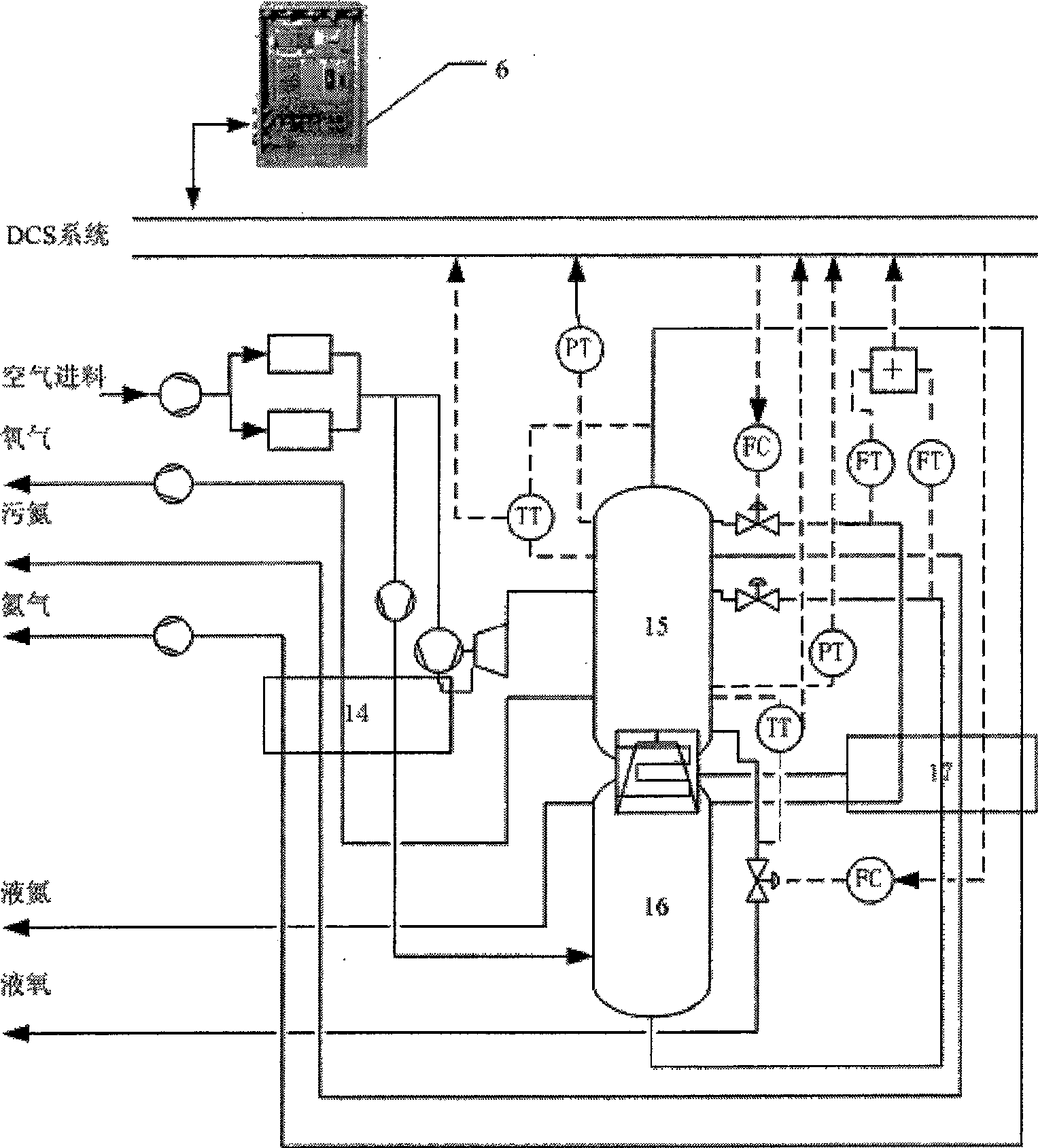

[0055] refer to Figure 1 to Figure 4 , a general model control system for an air separation tower, including an on-site intelligent instrument 2 directly connected to an air separation tower 1, a data storage device for storing historical data, and a host computer 6, an intelligent instrument 2, a data storage device, and an upper computer 6 are connected in sequence, and the host computer 6 is a general model controller, and the general model controller includes a composition inference control part and a general model control part, and the composition inference control part includes: a detection instrument module 7, Including temperature detection element and pressure detection element, used to detect the temperature and pressure of the upper tower of the air separation tower; I / O element module 9, used for electrical signals, and data signals in the controller and between the controller and DCS Transmission, component deduction module 10, used to infer components according ...

Embodiment 2

[0117] refer to Figure 1 to Figure 4 , a kind of control method realized with the general model control system of described air separation tower, described control method comprises the following steps:

[0118] (1) Determine the two-component set value Y of the air separation tower 1set 、X nset , and the sampling period T;

[0119] (2) After doing a step test around the set value, the historical data is obtained from the data storage device, obtained through the quadratic curve fitting module, and the nitrogen component Y in the nitrogen gas 1 The quadratic equation about the reflux R of the lower tower liquid nitrogen and liquid oxygen to the upper tower: Y 1 (k)=a 1 ×R(k) 2 , and the quadratic equation of the nitrogen component Xn in the product liquid oxygen with respect to the output flow L of the liquid oxygen product: X n (k)=a 2 ×L(k) 2 ;

[0120] (3) At each sampling time KT, the composition is inferred based on the temperature and pressure data obtained from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com