Cavity filter with rotation adjustable loop

A cavity filter and loop technology, applied to waveguide devices, circuits, electrical components, etc., can solve the problems of difficult to obtain strong coupling, difficult cable assembly, inconvenient adjustment, etc., to achieve simple structure, convenient debugging, The effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

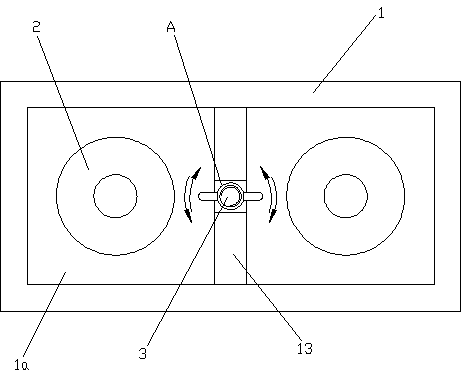

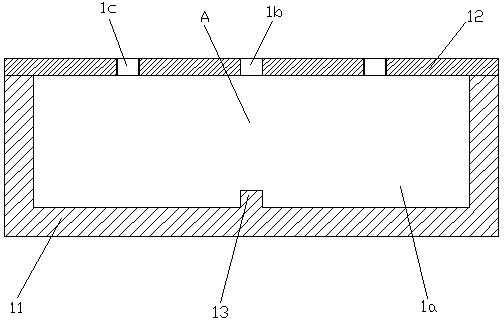

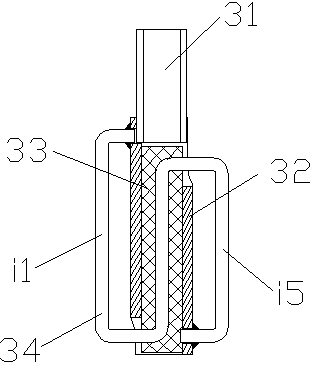

[0023] Figure 1 to Figure 6 Shown is the structural representation of the present invention.

[0024] The reference signs are: coupling window A, adjustment gap S, first coupling section i1, second coupling section i5, metal cavity box 1, dielectric resonator 1a, coupling adjustment screw hole 1b, tuning screw hole 1c, metal Shell 11, metal cover plate 12, partition 13, TM dielectric resonator 2, TM dielectric resonator rod 21, tuning screw 22, tuning nut 23, negative coupling adjustable loop 3, connection opening 3a, coupling adjustment screw 31, metal tube 32 , Medium pipe 33, coupling cable 34, set nut 4.

[0025] Such as Figures 1 to 6 As shown, a cavity filter with a rotary adjustable circuit of the present invention includes a rectangular metal cavity box 1 whose inner cavity is divided by a partition wall 13 to form at least two die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com