Prefabricated regenerated stone block for rockery, its fabrication process, regenerated stone rockery and its piling up method

A technology for pre-making and re-creating stone, which can be applied in decorative arts, patterns imitating three-dimensional effects, processes used to produce decorative surface effects, etc., and can solve problems such as re-creation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

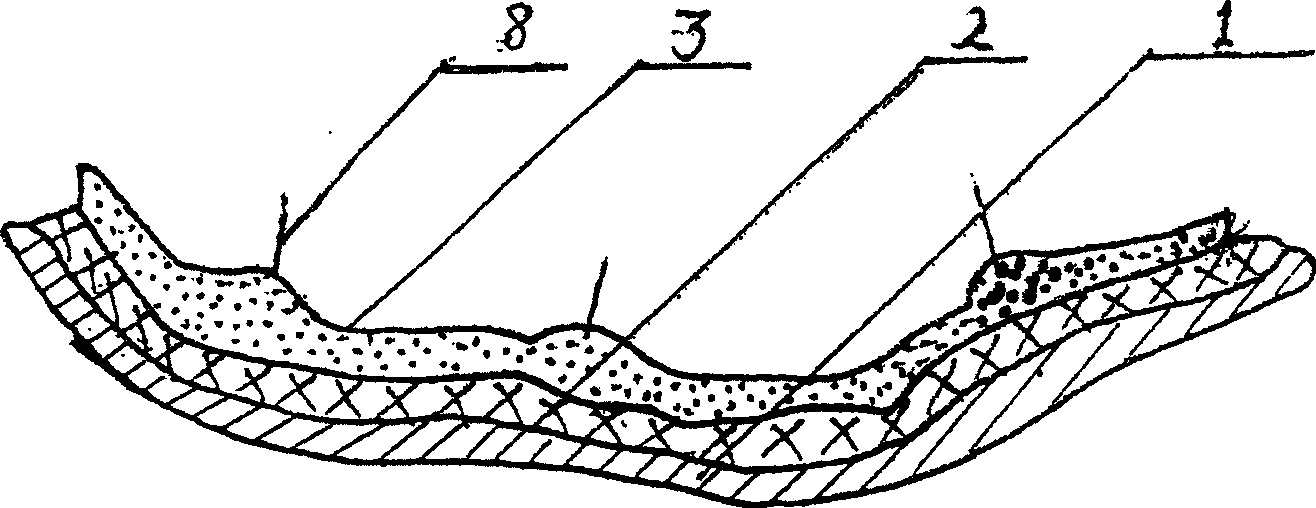

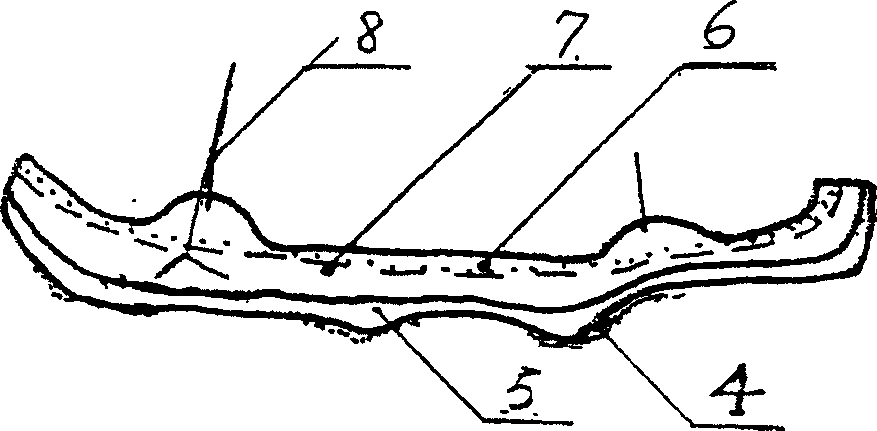

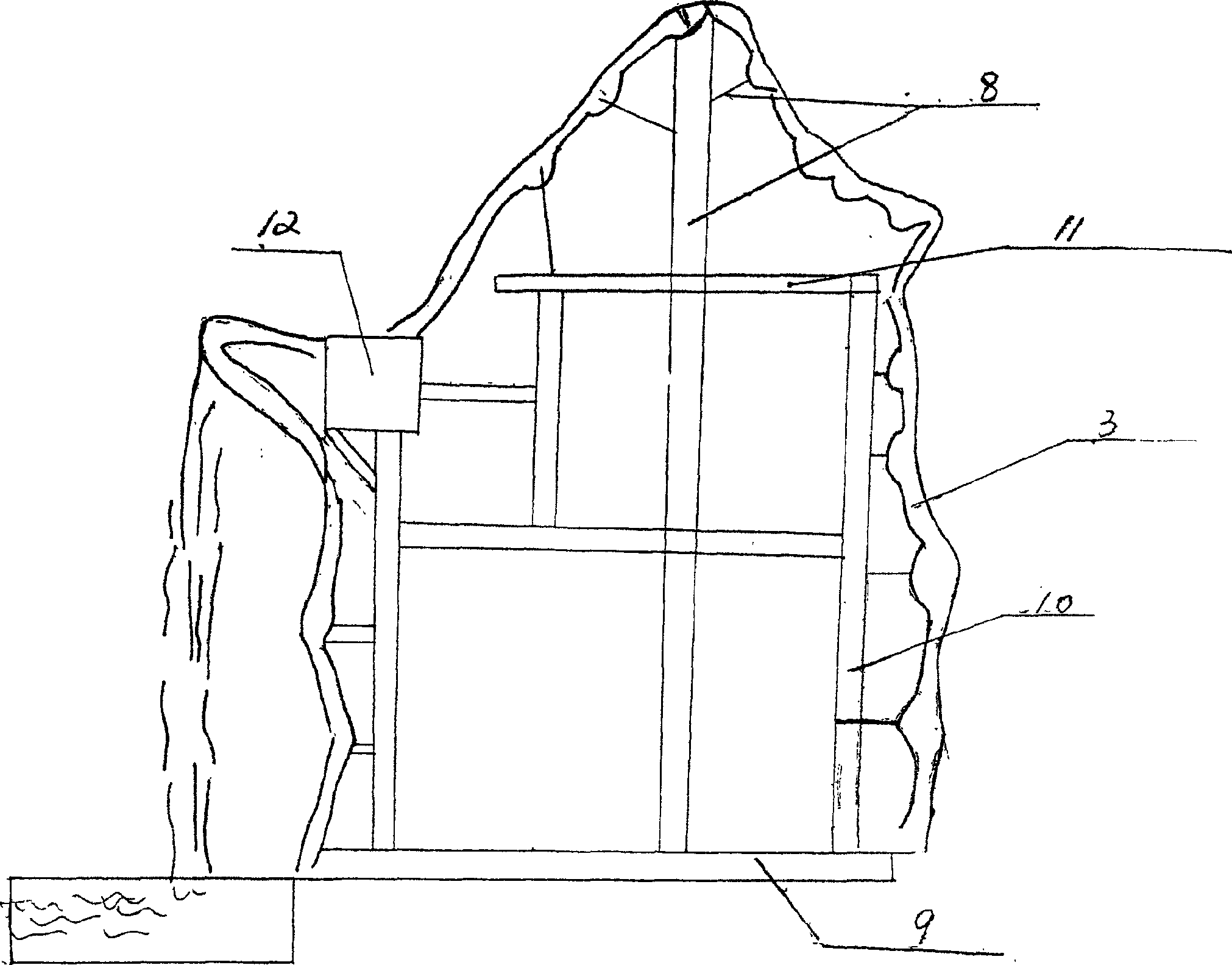

[0070] figure 1 It is a structural diagram of a prefabricated sheet of a reconstructed stone rockery, which includes: an outer mold layer 1, an inner mold layer 2 and rockery flakes 3. figure 2 It is a structural diagram of a reconstituted stone rockery sheet, which includes a mountain shadow layer 4, a decorative layer 5 and a structural layer 6, wherein the structural layer includes an alkali-resistant fiber net 7 and a support frame 8;

[0071] In the process of making the rockery flakes, the rockery prefabricated sheets are first made, and then the rockery prefabricated sheets are demoulded to obtain the rockery flakes 3 . The production process of the rockery prefabricated film includes mold making, painting the mountain shadow, spraying the decorative layer, filling the structural layer and cleaning. They are:

[0072] A Modeling process of reconstituted stone rockery prefabricated sheets:

[0073] (1) The master mold is cleaned, dried, and brushed with alkaline soap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com