A real stone paint for exterior walls prepared by using industrial waste liquid slag

A technology of liquid slag and real stone paint, which is applied in the coating and other directions, can solve the problems of imitation stone not being realistic enough, product fading, poor weather resistance, etc., and achieve excellent tensile bond strength, complete and firm particle structure, and excellent physical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1: The raw material composition ratio of the real stone paint for exterior walls prepared by using industrial waste liquid slag is calculated in parts by weight: 50 parts of water, 200 parts of pure acrylic polymer emulsion, 10 parts of film-forming aids, and 1 part of fungicide 1.5 parts of pH regulator, 10 parts of ethylene glycol, 2 parts of thickener, 700 parts of quartz sand, 20 parts of liquid slag, 10 parts of mica (silver white). It is shaped like sesame ash by scraping. The implementation performance is shown in Table 1.

Embodiment 2

[0014] Example 2: The raw material composition ratio of the real stone paint for exterior walls prepared by using industrial waste liquid slag is calculated in parts by weight: 100 parts of water, 150 parts of silicone acrylic polymer emulsion, 5 parts of film-forming aids, and 2 parts of fungicides 1 part, 1 part of pH regulator, 5 parts of propylene glycol, 1.5 parts of thickener, 300 parts of quartz sand, 350 parts of liquid slag, 100 parts of mica (black). It is formed by scraping to imitate diamond black. The implementation performance is shown in Table 1.

Embodiment 3

[0015] Example 3: The raw material composition ratio of the real stone paint for exterior walls prepared by using industrial waste liquid slag is calculated in parts by weight: 80 parts of water, 170 parts of pure acrylic polymer emulsion, 8 parts of film-forming aids, and 1.5 parts of fungicides 1.2 parts of pH regulator, 8 parts of ethylene glycol, 18 parts of thickener, 600 parts of quartz sand, 100 parts of liquid slag, 50 parts of mica (golden yellow). It is shaped like Kara Malikon by scraping coating. The implementation performance is shown in Table 1.

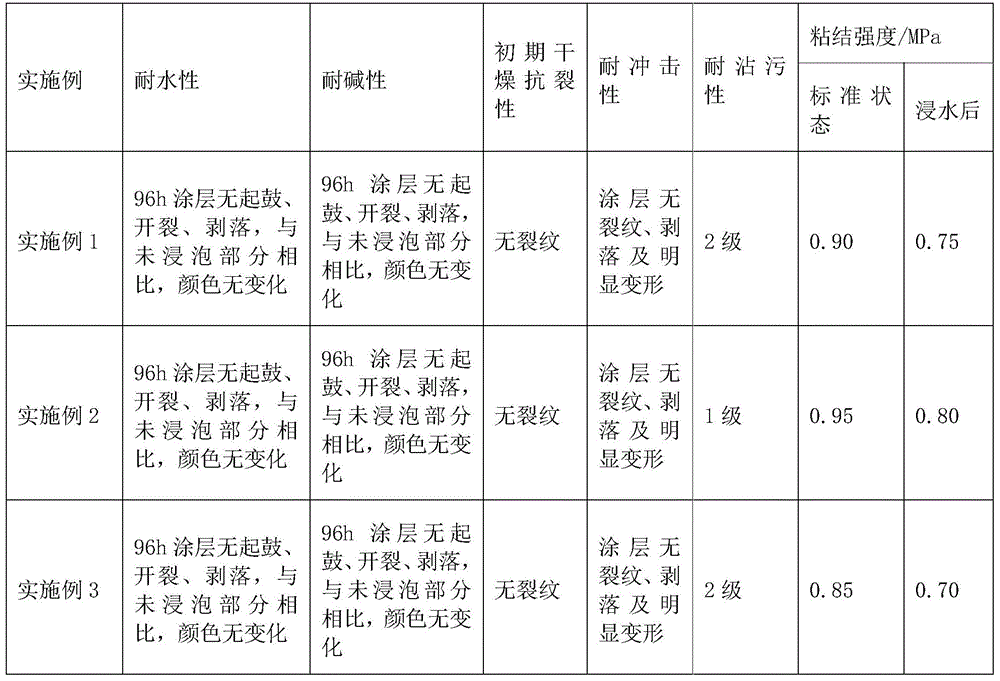

[0016] Table 1 The performance test results of the real stone paint for exterior walls prepared by using industrial waste liquid slag obtained in the examples

[0017]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com