Conductive cement and method for preparing same

A technology of conductive cement and cement, which is applied in the preparation of conductive cement and the field of conductive cement, can solve the problems of high price, low concrete strength, unstable conductivity, etc., achieve recycling, reduce cost, and reduce environmental impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

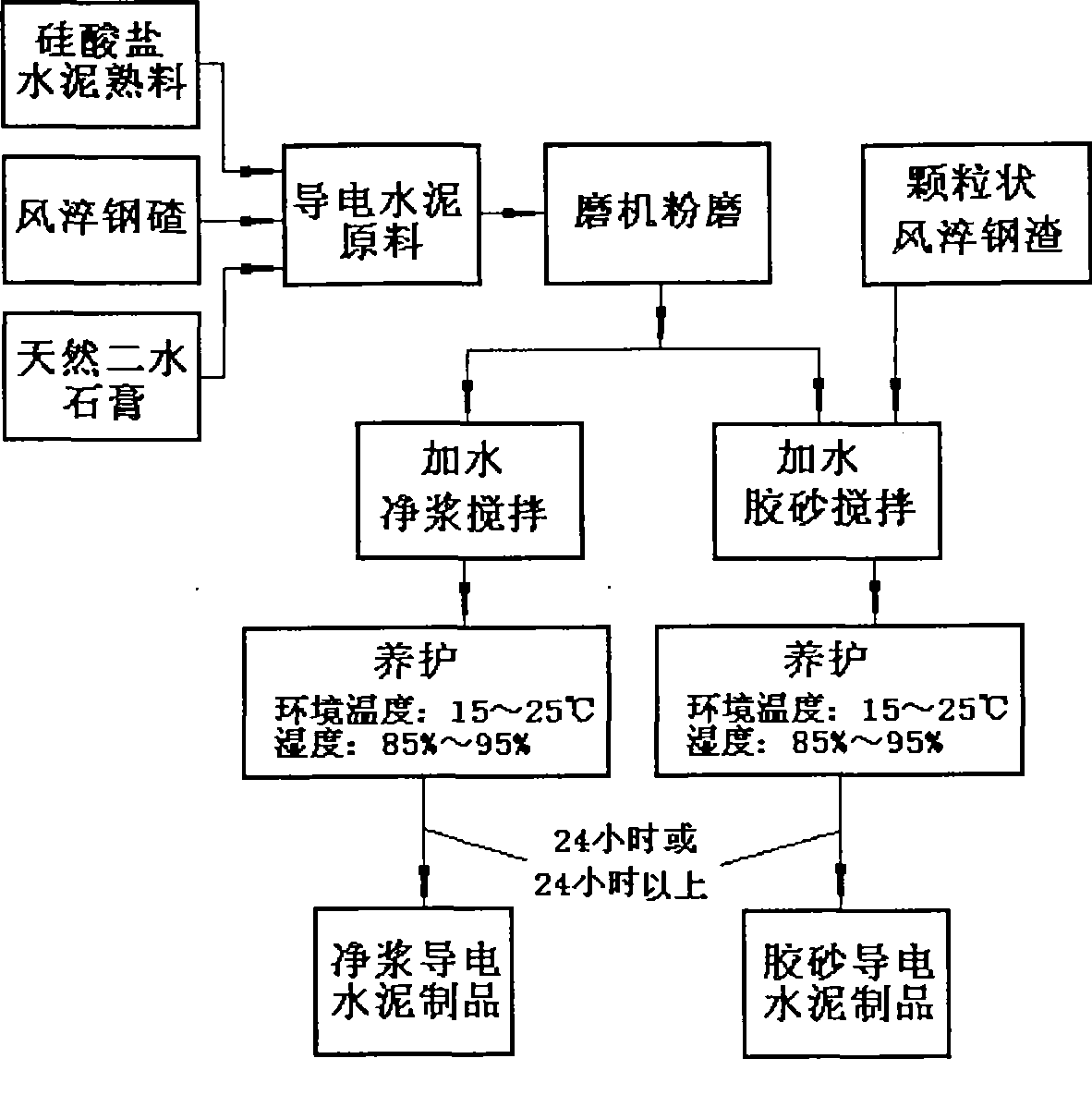

[0046] When the above-mentioned preparation method is used to make clean slurry conductive products, the mass ratio of water to the conductive cement raw materials is 0.3:1, the clean slurry is stirred and molded, and cured for 24 hours or more to condense.

[0047] In addition, when the above-mentioned preparation method is used to make plastic sand conductive products, the raw material of the above-mentioned conductive cement is used, and in the c) step of the process, granular wind-quenched steel slag is added, wherein water, the above-mentioned The mass ratio of the raw material of the conductive cement to the granular wind-quenched steel slag is 0.3:1:3.8, the mortar is stirred and molded, and cured for 24 hours or more to solidify.

[0048] The maximum particle size of the above-mentioned granular air-quenched steel slag is ≦20mm. Furthermore, the maximum particle size of the granular air-quenched steel slag is ≦10mm. The selection of particles of different sizes for ai...

Embodiment 1

[0050] Embodiment 1: The described conductive cement is to use 45% Portland cement clinker, 50% wind-quenched steel slag, and the rest are natural dihydrate gypsum to grind and mix to make the raw material clean paste conductive product of conductive cement with water and The mass ratio of the raw materials of the conductive cement is 0.3:1, the pure slurry is stirred and molded, and cured for 24 hours or more at an ambient temperature of 15-25°C and a humidity of 85%-95%. Its electrical conductivity is very good, but the setting time of cement is slightly longer and its strength is slightly lower.

[0051] The technical scheme of ambient temperature and humidity during specific implementation is: the described ambient temperature is 20° C.; the described humidity is 90%.

Embodiment 2

[0052] Embodiment 2: The conductive cement is made by mixing and grinding 78% Portland cement clinker, 20% wind-quenched steel slag, and 2% natural dihydrate gypsum. The clean slurry conductive product is formed by stirring the clean slurry with the mass ratio of water and conductive cement raw materials as 0.3:1, and curing for 24 hours or more under the ambient temperature of 15-25°C and the humidity of 85%-95%. Its electrical conductivity is good, but the setting time of cement is fast and its strength is high.

[0053] The environment for measuring various performance indexes of the conductive cement is: the ambient temperature is 20°C; the humidity is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com