Three-dimensional reinforced hydrophobic rock wool insulation board

A thermal insulation board, three-dimensional technology, applied in the direction of thermal insulation, building components, etc., can solve the problems of low tensile strength, reduced thermal insulation performance, poor wind resistance, etc., to achieve high tensile strength, low water absorption, and good impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

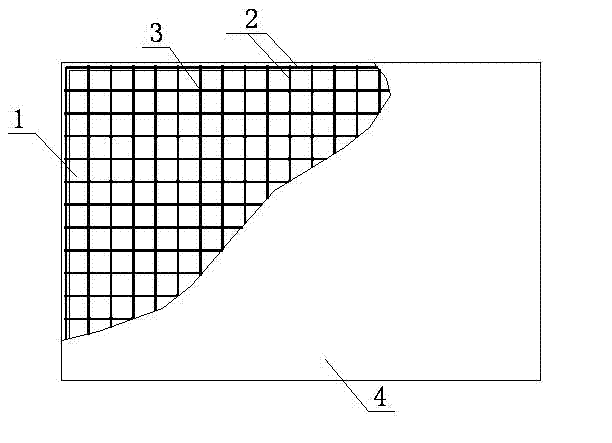

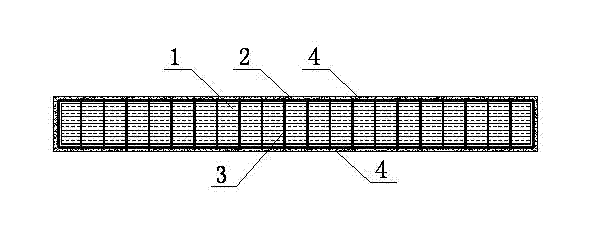

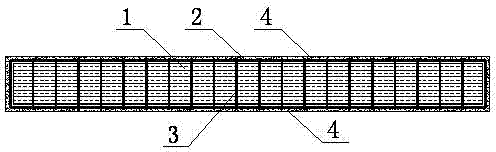

[0023] Example 1: The rock wool insulation board 1 used has a thermal conductivity of 0.045 W / (m.K), a thickness of 50mm, and a combustion performance grade of A, while the high-temperature-resistant reinforcing fiber adopts a glass phase, and the spacing is 10mm, Glass fibers with a diameter of 50 μm are woven into a grid as two-dimensional high-temperature-resistant reinforcing fibers 2, and the horizontal plane of the rock wool insulation board 1 is two-dimensionally reinforced in the horizontal direction; High-temperature reinforcing fiber 3 is used to vertically reinforce the rock wool insulation board 1 perpendicular to the horizontal plane; use hydrophobic cement slurry as the hydrophobic material to paint on the surface of the rock wool insulation board 1 to make a hydrophobic protective layer with a thickness of 2 mm 4.

Embodiment 2

[0024] Example 2: The rock wool insulation board 1 used has a thermal conductivity of 0.042 W / (m K), a thickness of 100mm, and a combustion performance grade of A, while the high-temperature-resistant reinforcing fiber adopts a glass phase, and the spacing is 60mm, Glass fibers with a diameter of 220 μm are woven into a grid as two-dimensional high-temperature-resistant reinforcing fibers 2, and the horizontal surface of the rock wool insulation board 1 is two-dimensionally reinforced in the horizontal direction; High-temperature reinforcing fiber 3 is used to vertically strengthen the rock wool insulation board 1 perpendicular to the horizontal plane; use hydrophobic cement slurry as the hydrophobic material to brush on the surface of the rock wool insulation board 1 to make a hydrophobic protection with a thickness of 2.5mm. Layer 4.

Embodiment 3

[0025] Example 3: The rock wool insulation board 1 used has a thermal conductivity of 0.048 W / (m.K), a thickness of 20mm, and a combustion performance grade of A, while the high-temperature-resistant reinforcing fiber adopts a glass phase, and the spacing is 90mm, Glass fibers with a diameter of 400 μm are woven into grids as two-dimensional high-temperature-resistant reinforcing fibers 2, and the horizontal plane of the rock wool insulation board 1 is two-dimensionally reinforced in the horizontal direction; High-temperature reinforcing fiber 3 is used to vertically reinforce the rock wool insulation board 1 perpendicular to the horizontal direction; use hydrophobic cement slurry as the hydrophobic material to paint on the surface of the rock wool insulation board 1 to make a hydrophobic protective layer with a thickness of 4mm 4.

[0026] The main properties of the three-dimensional reinforced hydrophobic rock wool insulation board formed according to the above three embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com