Weaving method of basalt fiber, glass fiber and polypropylene fiber woven fabric

A technology of basalt fiber and polypropylene fiber, which is applied in the direction of fabrics, textiles, papermaking, textiles, etc., to achieve the effect of improving the weaveability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

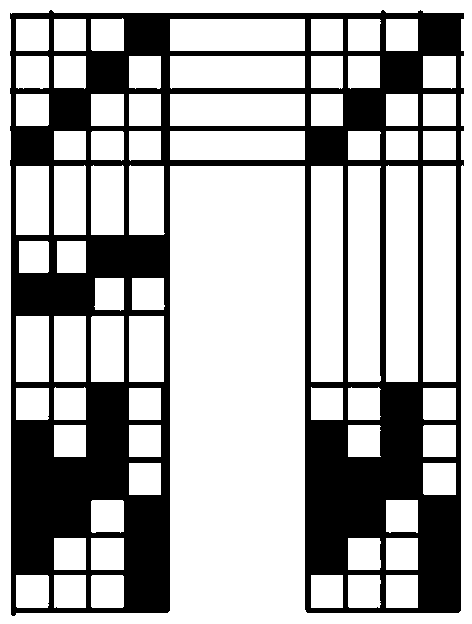

[0016] A weaving method of basalt fiber, glass fiber and polypropylene fiber woven fabric, the number of interweaving layers of warp yarns is 3 layers; According to the interweaving law of basalt fiber, glass fiber and polypropylene fiber three-dimensional orthogonal woven fabric, according to the interweaving law of each layer of warp and weft yarn, draw the structure schematic diagram of three-dimensional orthogonal woven fabric of basalt fiber, glass fiber and polypropylene fiber; According to the schematic diagram of the three-dimensional orthogonal woven fabric of basalt fiber, glass fiber and polypropylene fiber, draw the organization diagram of the three-dimensional orthogonal woven fabric of basalt fiber, glass fiber and polypropylene fiber, through the three-dimensional The weave diagram of the interlaced fabric The upper machine diagram of the three-dimensional orthogonal woven fabric of basalt fiber, glass fiber and polypropylene fiber is obtained, as shown in figur...

Embodiment 2

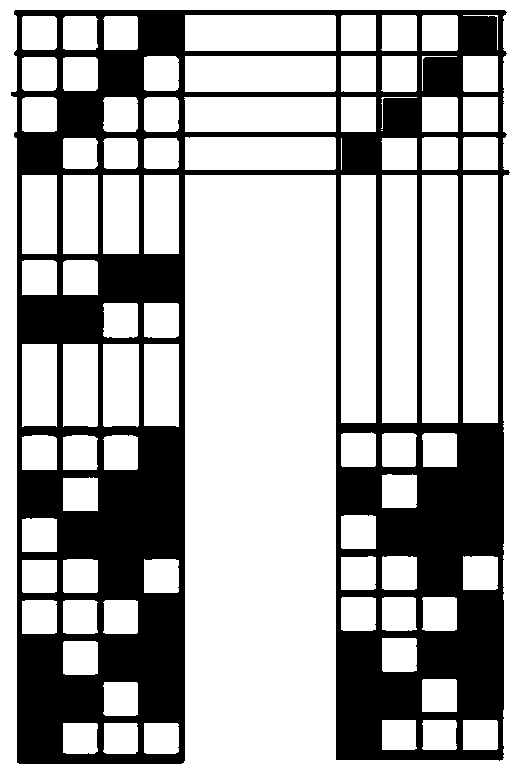

[0019] A weaving method of basalt fiber, glass fiber and polypropylene fiber woven fabric, the number of interweaving layers of warp yarns is 2 layers; According to the interweaving law of basalt fiber, glass fiber and polypropylene fiber three-dimensional angle interlocking woven fabric, draw the structure of basalt fiber, glass fiber and polypropylene fiber three-dimensional angle interlocking woven fabric according to the interweaving law of each layer of warp and weft yarn Schematic diagram; according to the structural schematic diagram of the three-dimensional angular interlocking woven fabric of basalt fiber, glass fiber and polypropylene fiber, the organization diagram of the three-dimensional angular interlocking woven fabric of basalt fiber, glass fiber and polypropylene fiber is drawn, and the The organization diagram of the three-dimensional angular interlocking woven fabric of acrylic fiber The upper machine diagram of the three-dimensional angular interlocking wove...

Embodiment 3

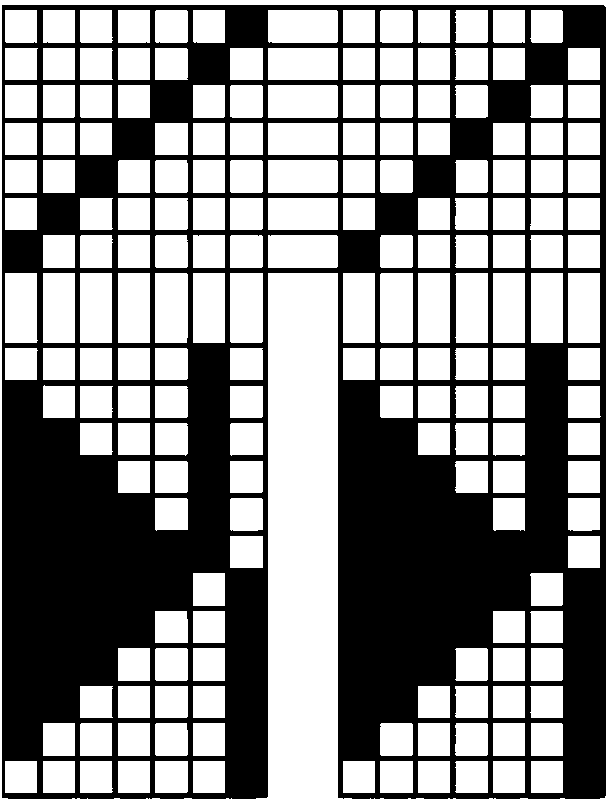

[0022] A weaving method of basalt fiber, glass fiber and polypropylene fiber woven fabric, the number of interweaving layers of warp yarns is 6 layers; According to the interweaving law of basalt fiber, glass fiber and polypropylene fiber three-dimensional orthogonal woven fabric, according to the interweaving law of each layer of warp and weft yarn, draw the structure schematic diagram of three-dimensional orthogonal woven fabric of basalt fiber, glass fiber and polypropylene fiber; According to the schematic diagram of the three-dimensional orthogonal woven fabric of basalt fiber, glass fiber and polypropylene fiber, draw the organization diagram of the three-dimensional orthogonal woven fabric of basalt fiber, glass fiber and polypropylene fiber, through the three-dimensional The weave diagram of the interlaced fabric The upper machine diagram of the three-dimensional orthogonal woven fabric of basalt fiber, glass fiber and polypropylene fiber is obtained, as shown in imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com