Consumption-reducing and life-prolonging method for engine and device therefor

An engine and supercharger technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve the problems of mechanical interaction damage of metal parts, affect engine performance, load increase, etc., and achieve significant economic and social benefits. , The effect of reducing energy consumption and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

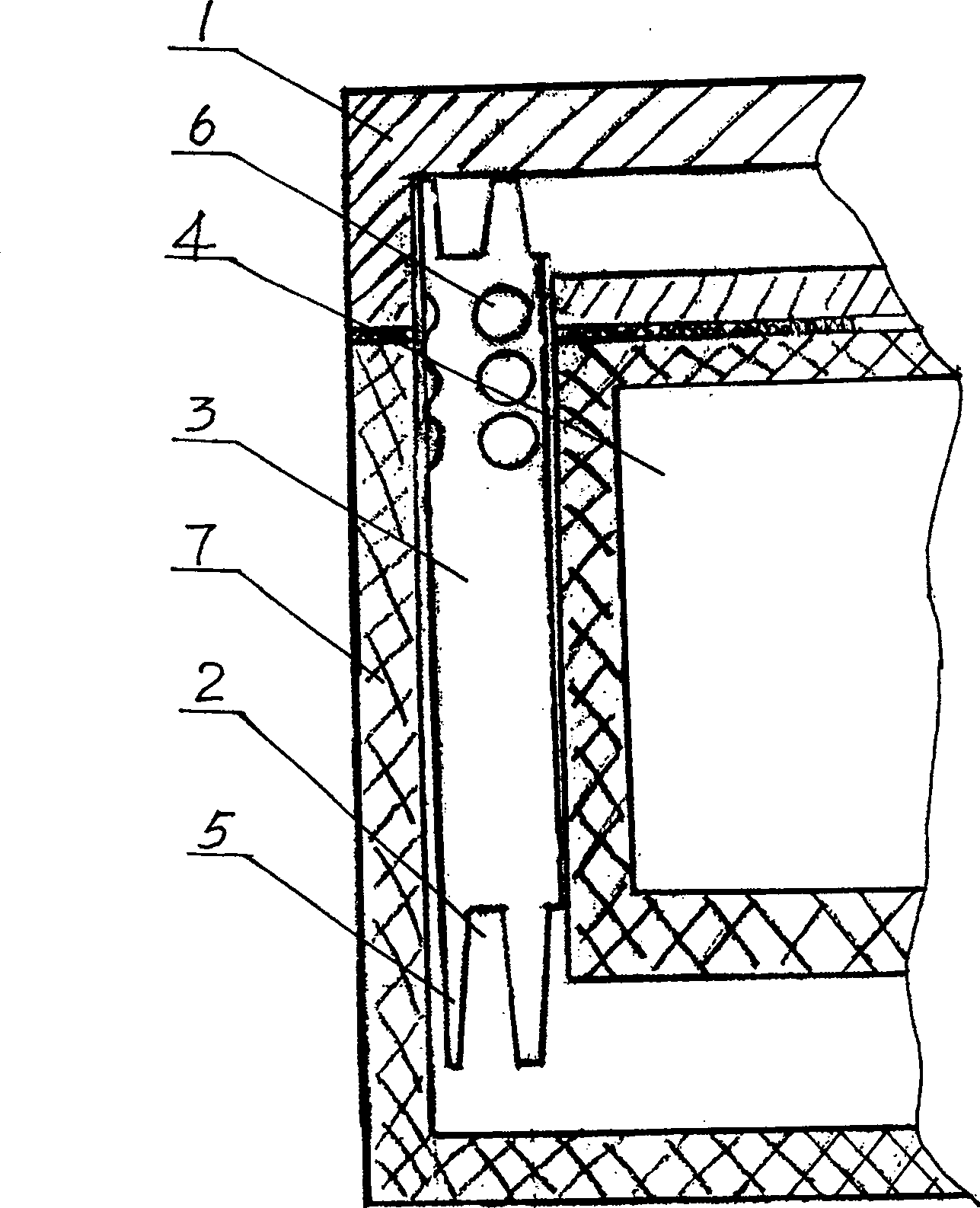

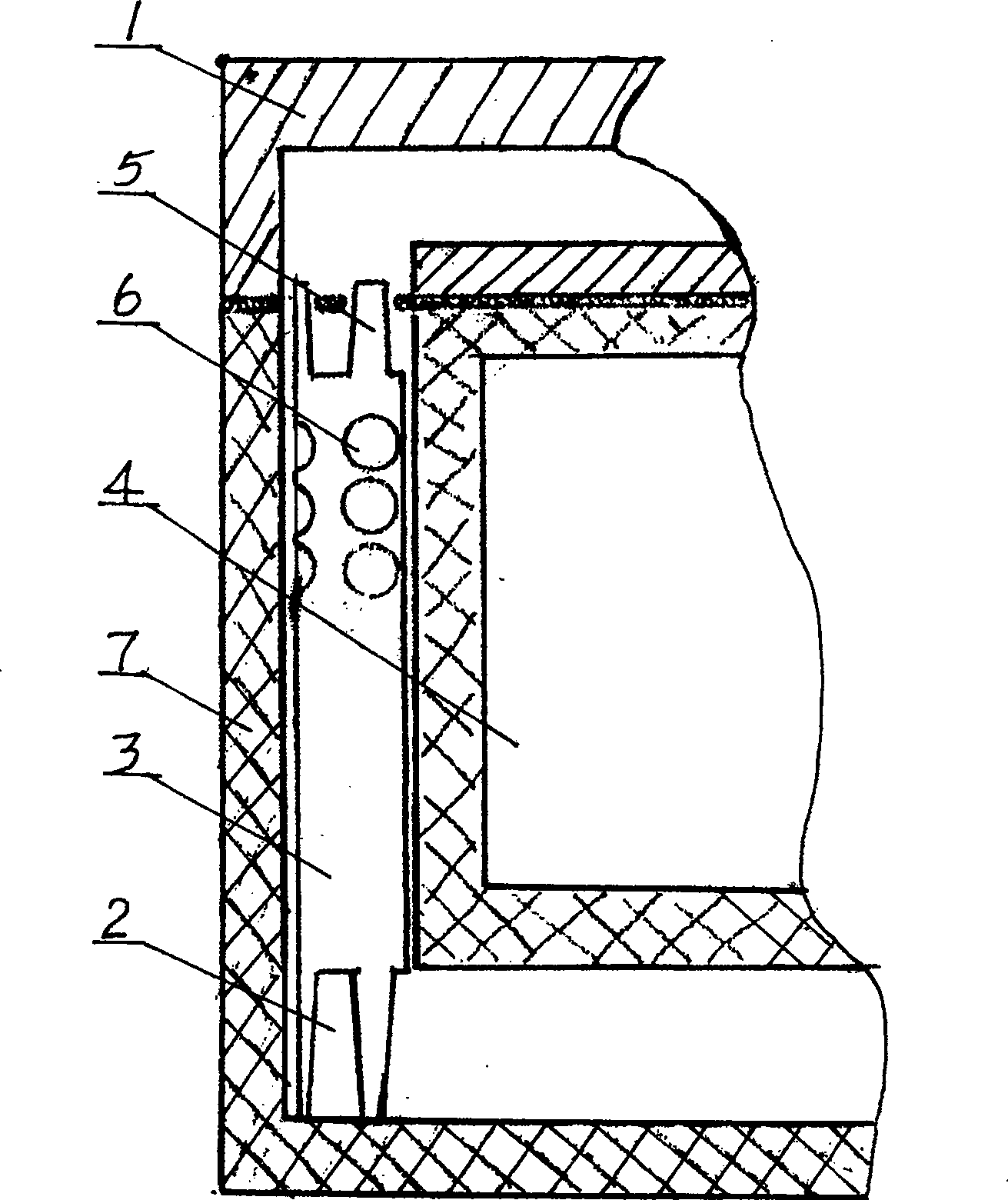

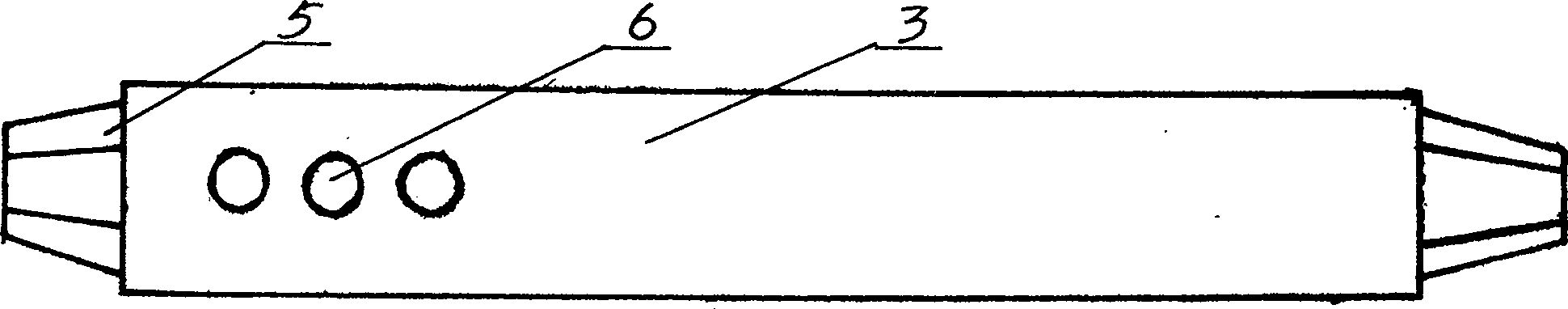

[0011] The method of the present invention is to insert a tubular supercharger 3 in the output main oil passage 2 where the cylinder block 7 of the engine is connected to the cylinder head 1; For the claw formed by platform 3, several groups of through holes 6 are arranged at intervals around the tube wall near the claw at one end; the supercharger 3 is made of aluminum alloy tube, and the thickness of the tube wall is controlled at 1.5-2.5mm; the two ends of the tubular supercharger 3 The spaced bosses can be composed of two bosses 5 or three bosses 5, each boss 5 is equidistantly spaced, and each boss 5 has a taper in the axial direction; the supercharger 3 tube wall has a through hole 6 at one end. The diameter of the output port of the spaced boss 5 is smaller than the diameter of the input port of the spaced boss 5 at the other end; the tube wall of the supercharger 3 has a through hole, and the height of the boss 5 at one end is 2-3mm smaller than the diameter of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com