Cutter

A technology for cutting machines and cutting knives, which is applied in the direction of shearing devices, mechanical equipment, metal sawing equipment, etc. It can solve the problems of no tension adjustment, no deceleration function, and the transmission unit cannot transmit rotational force, etc., to achieve reduction The effect of failure rate, low repair cost and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

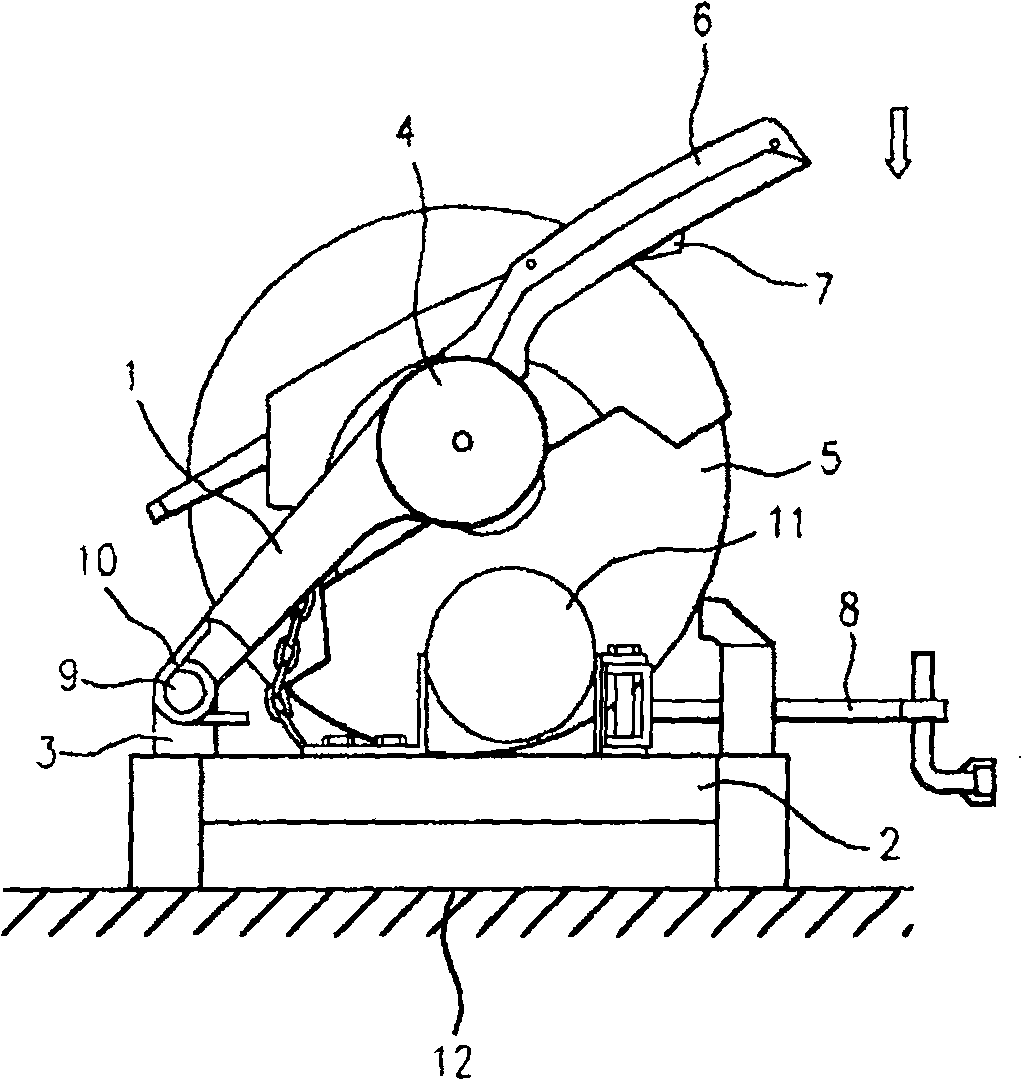

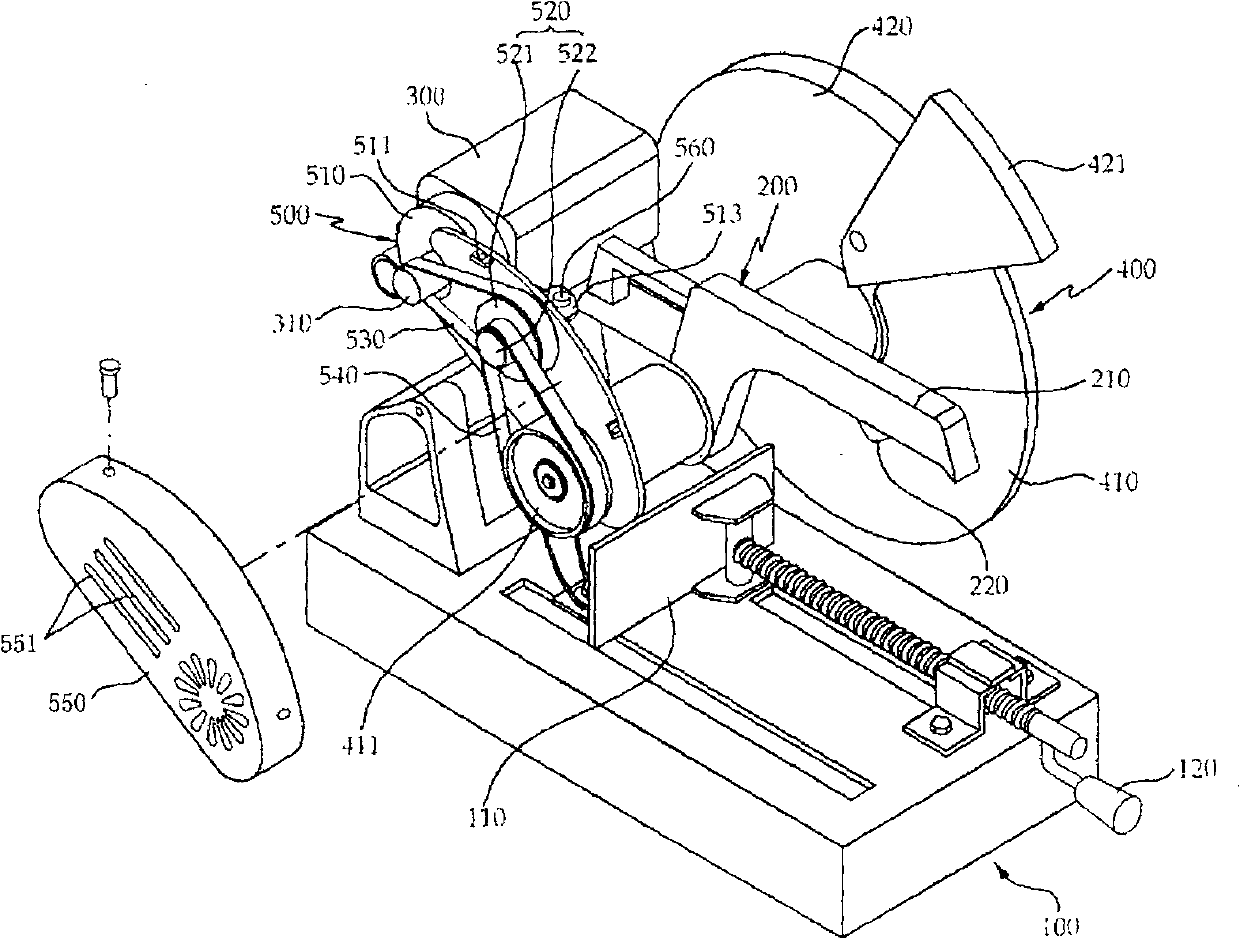

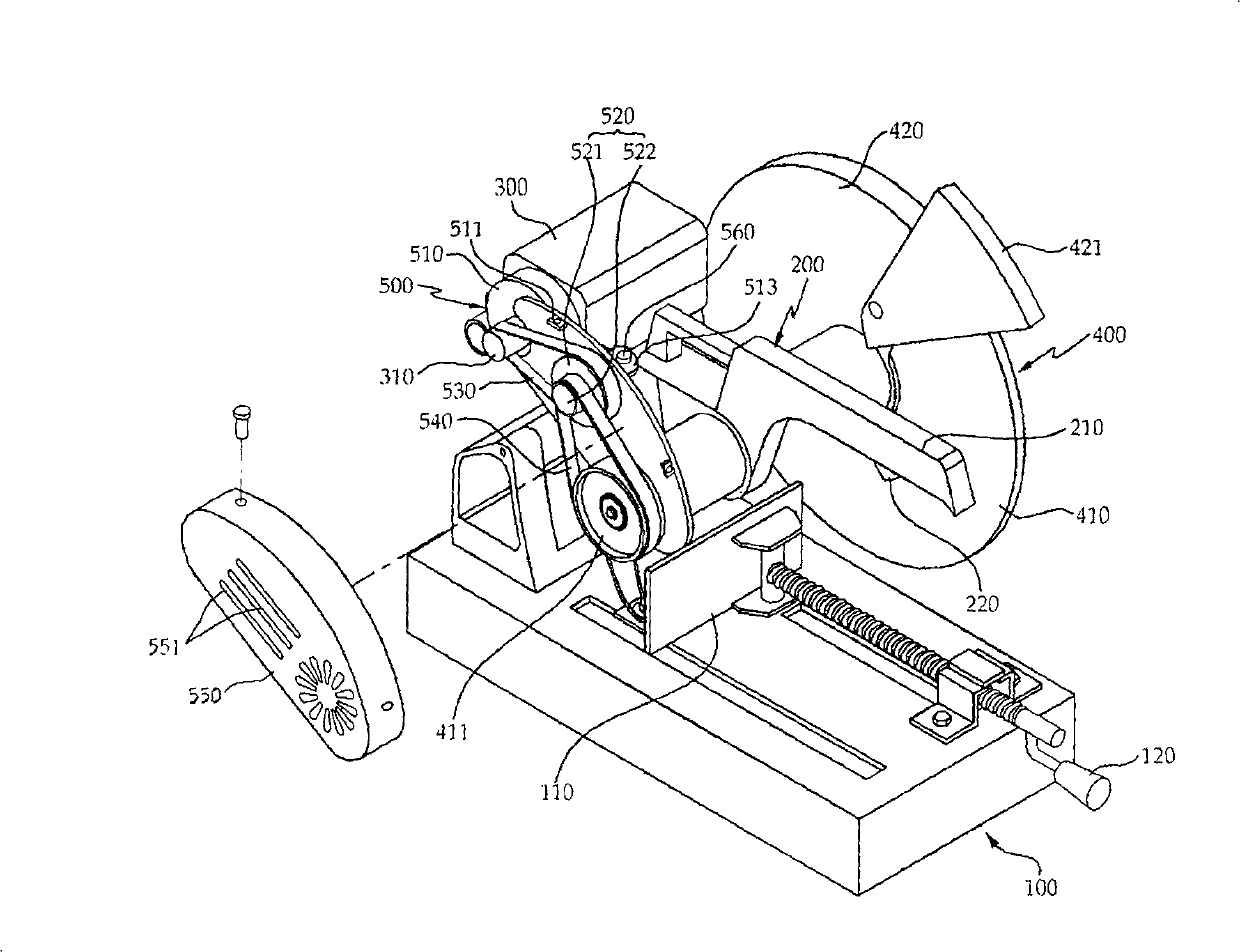

[0051]Below, refer to the attached Figure 2 to Figure 7 , the ideal embodiment of the present invention will be described in detail.

[0052] Such as Figure 2 to Figure 4 As shown, the cutting machine of the present invention cuts hard metal through a cutting knife rotating at a high speed, and it includes: an operating table 100 arranged on the ground; a frame 200, one end of which is rotatably fixed on the above-mentioned operating table 100, The other end is provided with a switch; the motor 300 is arranged on one end of the above-mentioned frame 200; the cutting part 400 is arranged on the side of the above-mentioned frame 200, and is provided with a cutting knife; the transmission part 500 connects the above-mentioned motor 300 and the cutting knife.

[0053] The above-mentioned console 100 is used to place workpieces, one end of which is rotatably hinged with a frame 200, on which a vise 110 is arranged, the above-mentioned vise can be moved back and forth by the rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com