Controllable hot melt adhesive spinning method and device

A technology of spinning device and hot-melt adhesive, applied in the direction of ejecting device, liquid ejecting device, etc., can solve the problems of easy entanglement, flashing, and large amount of glue consumption of rubber threads, saving compressed air, good sealing performance, The effect of saving glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below according to the drawings and specific embodiments.

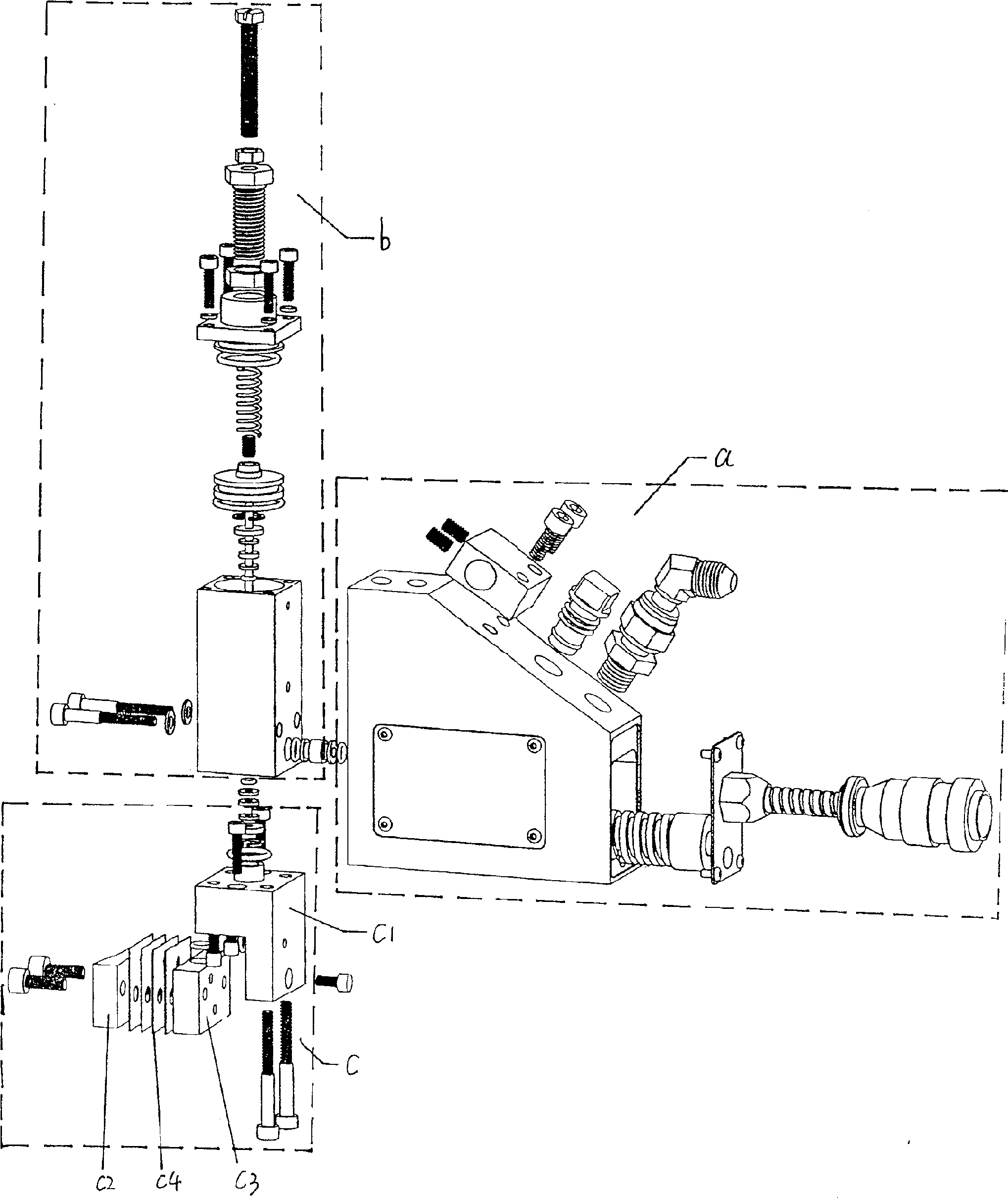

[0033] figure 1 Shown is a device for implementing the method of the present invention, a controllable hot-melt adhesive spinning device, including a heating seat a, used to heat each part of the hot-melt adhesive controllable spinning device and the hot melt adhesive and compression Air. The heating seat a also includes a heating rod, on which a spiral compressed air channel is processed to increase the heat exchange area of the compressed air and increase the temperature of the compressed air.

[0034] The needle valve body b is used to control the supply of hot melt adhesive, and the pneumatically controlled hot melt adhesive flow valve controls the on-off of the glue channel to complete the intermittent coating of the sprayed glue. The needle valve body b includes a cylinder plug and a striker, etc., which can realize the action of air opening and air clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com