High-tension steel plate with excellent toughness for high heat energy welding heat influence part

A technology of steel plate and heat input, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of difficulty in miniaturization, and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

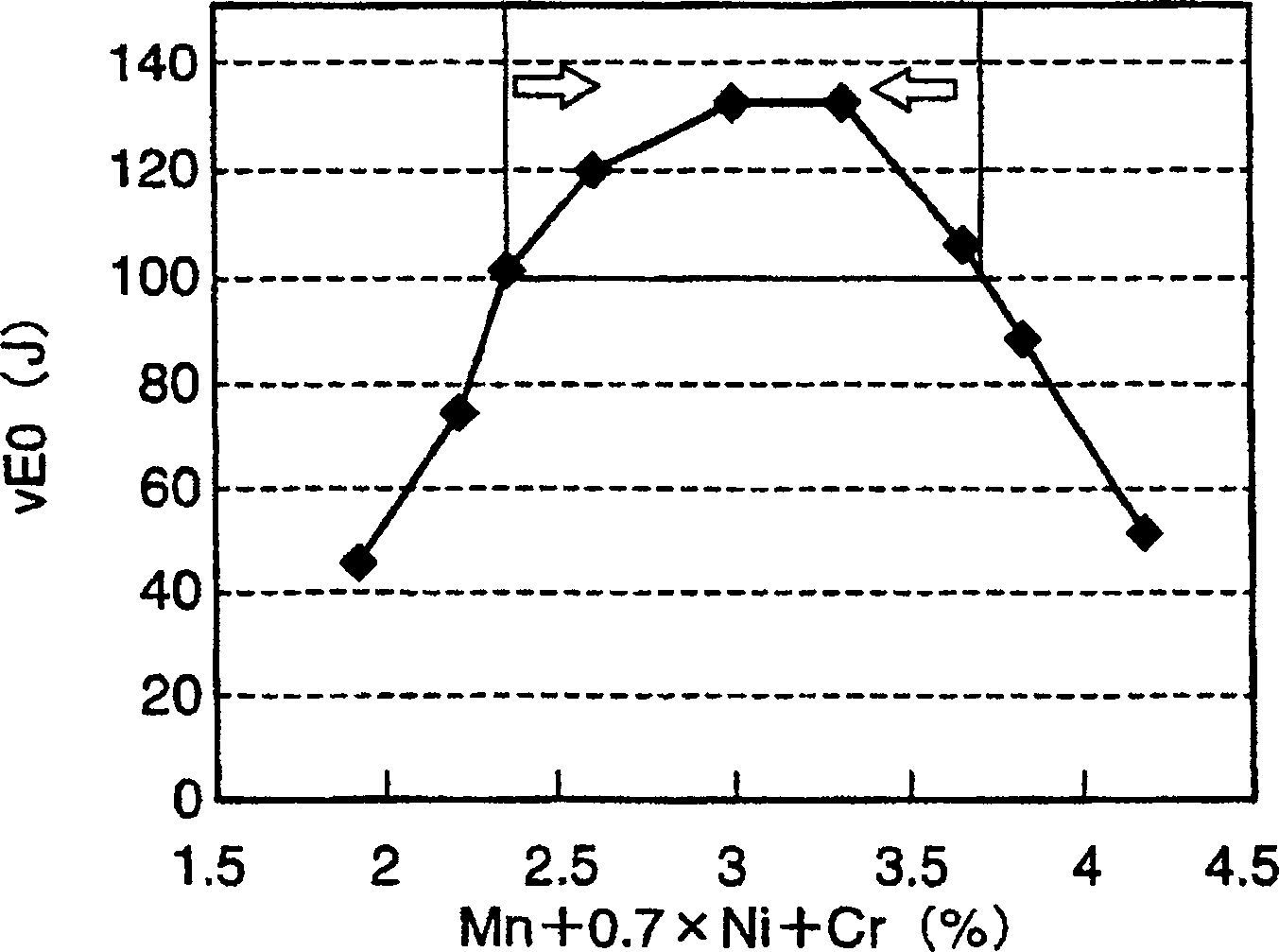

[0025] The inventors of the present invention have intensively studied to obtain a high-tensile steel sheet excellent in HAZ toughness (hereinafter simply referred to as "HAZ" toughness) when welding with high heat energy exceeding 500 kJ / cm. As a result, it was found as follows, thereby conceiving the present invention:

[0026] (i) In order to stabilize and ensure the high toughness of the heat-affected zone, it can be realized according to the following points:

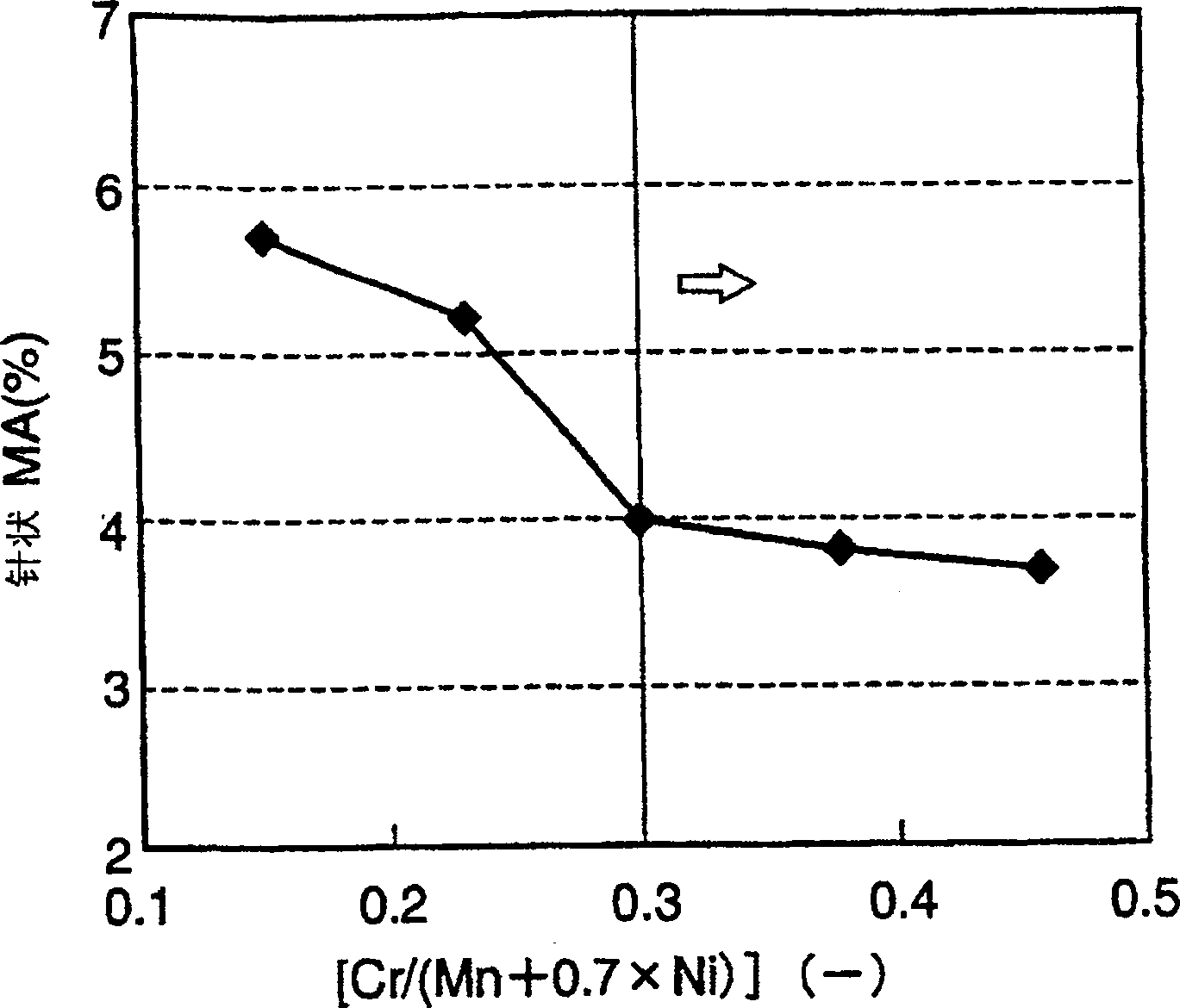

[0027] Not only use extremely low C to inhibit MA, but also control the form of MA (specifically, inhibit the formation of needle-like MA);

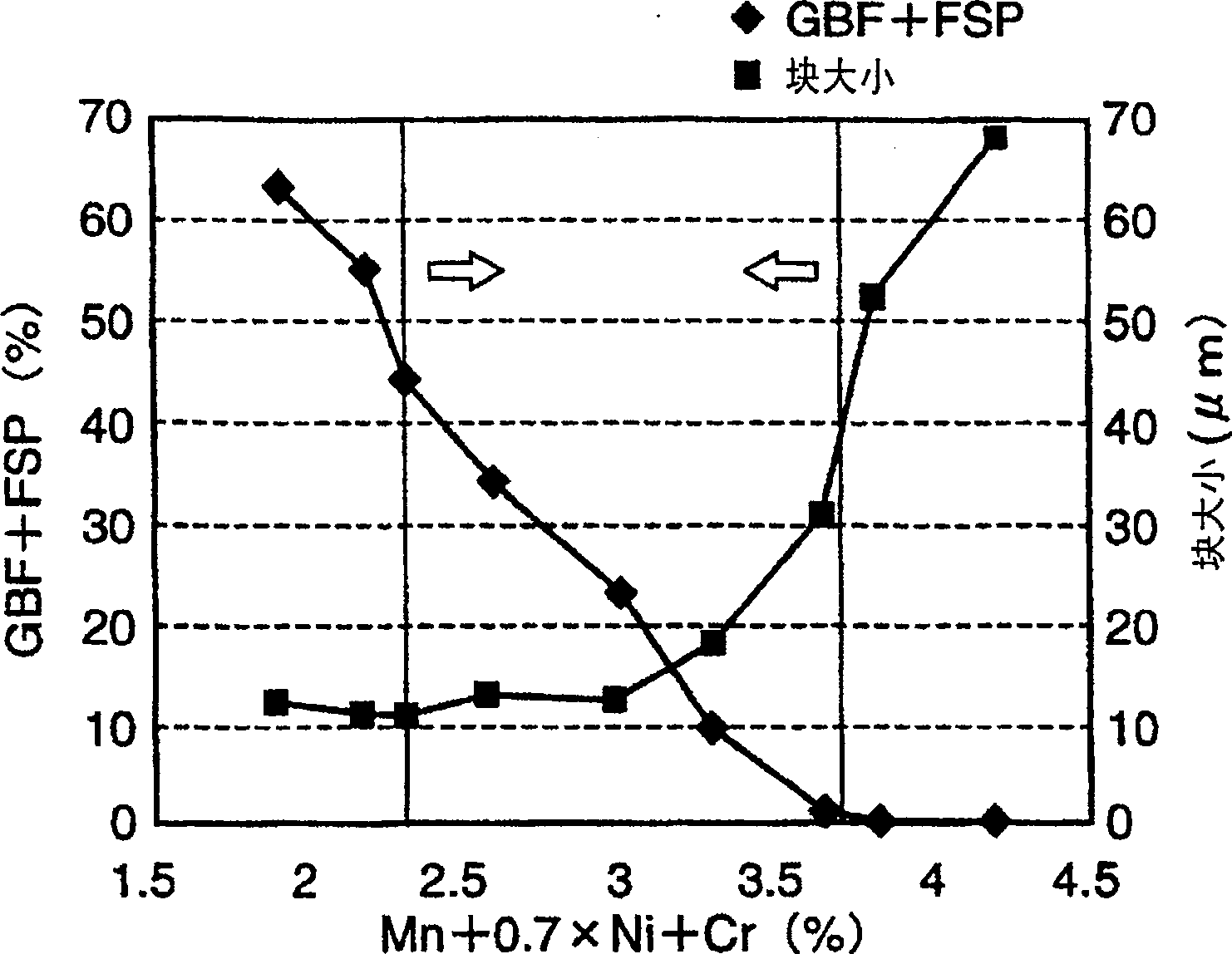

[0028] Coarse structure that inhibits growth at γ grain boundaries [grain boundary ferrite (GBF) + side lath ferrite (FSP)];

[0029] · It is necessary to realize the miniaturization of the block size of the transformation structure in the γ grain. In the present invention, Mn, Ni, and Cr, which are hardenability improving elements, are appropriately contained,

[0030] (ii...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com